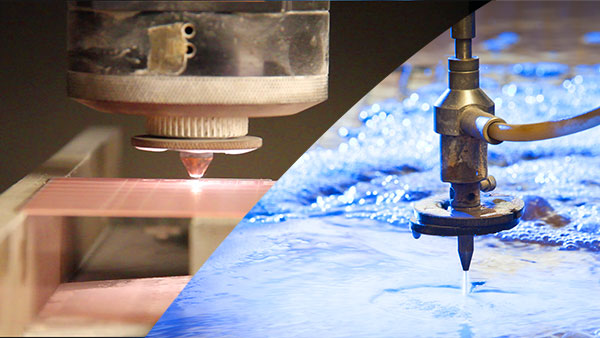

Differences Between Laser Cutting and Waterjet Cutting- A brief introdction

The differences between these two approaches don’t just lie in their methods but in their results and applications, too. When choosing between laser vs. waterjet cutting in your applications, consider the following:

Methods: Water jet cutting is a cutting method in which high-pressure water is paired with an abrasive, such as garnet, to erode materials at a fast rate, thus creating a cut. On the other hand, a laser cutter uses a CO2 gas for laser energy, making a rapid heating process that melts or vaporizes the material. The laser beam is focused on an area by adjusting the lens to create a better cut.

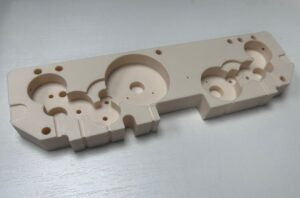

Materials: Both laser and waterjet are excellent choices to cut metals. Waterjet cutting is better suited for thicker, more rigid materials than laser cutting because of its high-pressure capabilities. Any required secondary operations will help determine the best technology for the job.

Precision: Laser cutting delivers exceptionally high accuracy, reaching tolerances of +/-0.005″, depending on the speed of the laser. Waterjet cutting typically holds a tolerance of +/- 0.03″.

Speed: Laser cutting is generally faster than waterjet cutting and cuts more inches per minute.

Costs: In terms of laser vs. waterjet cost, laser cutting is a more economical option as it can cut parts faster. Waterjet cutting is comparatively expensive, requiring many components to run properly, including a high-pressure pump, abrasive materials, and cutting heads.

Component cleanup: Laser cutting can sometimes leave a few burrs on the cut surfaces of the components. The components then require deburring for optimal smoothness, functionality, and safety. On the other hand, waterjet cutting generally necessitates minimal cleanup after cutting — the cut components are smooth and ready to go.

The point of this article is not to decide which is best between laser cutting and waterjet cutting but to point out their differences and to help you decide which one is best for your application.

To learn more cutting information, click HERE for a detailed article.