What is Cutting Speed, Feed Rate and Depth of Cut in CNC machining?

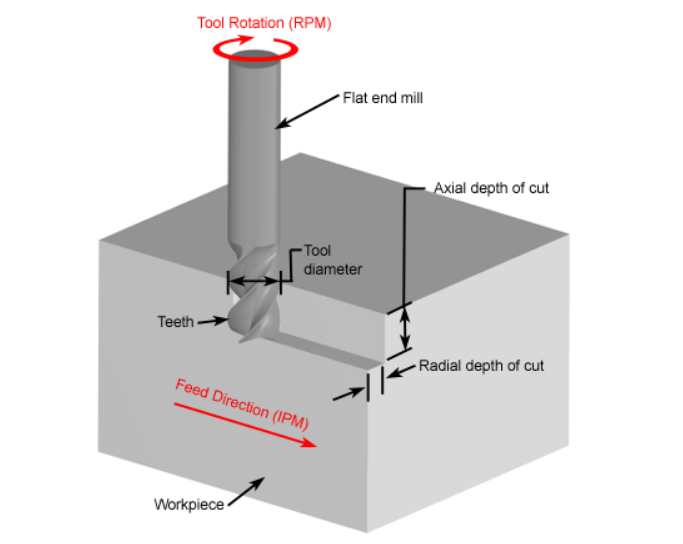

CNC machining is a material reduction manufacturing process that involves cutting off material fragments until the final product is obtained. Therefore, first of all, the mechanic needs to know the amount of material that the machine will shear in one rotation and the movement speed of the CNC machine.

When designing products, considering Cutting speed, feed rate and depth of cut in advance will optimize the entire processing process. This article will provide a detailed explanation of their principles

What is cutting speed?

When using CNC machines, cutting speeds are important to understand as they can determine the efficiency your production can achieve. Having a cutting speed that is too high can incur extra costs as the cutting edge deteriorates quickly, but conversely, a low speed can reduce productivity and production rates.

Cutting speed is defined as the speed (in meters per minute (m/min) or in feet per minute (ft/min.)) of a tool when it is cutting the work.

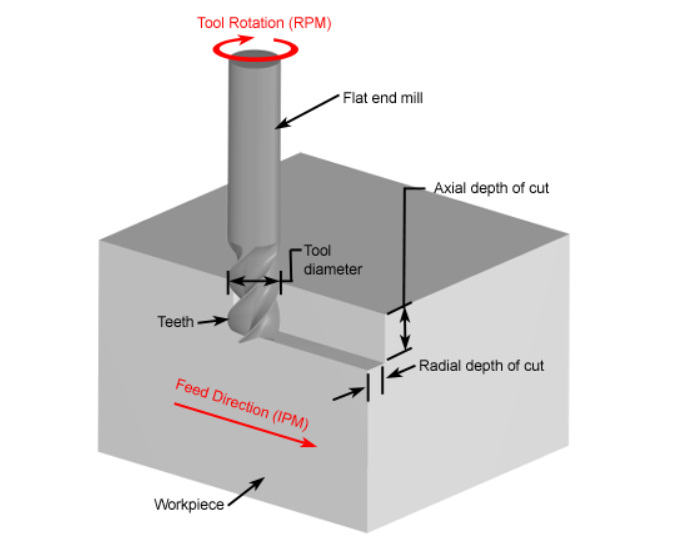

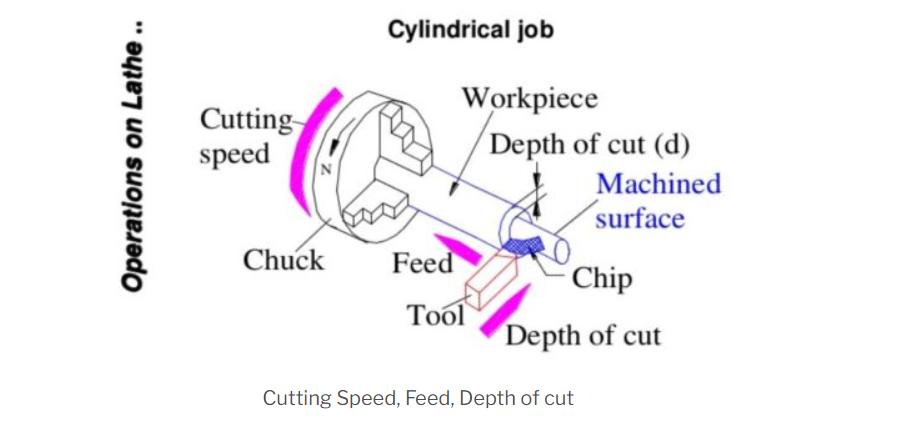

On a rotary tool such as a drill or end mill, this is a measure of how fast its periphery spins relative to the workpiece clamped to the table. It’s essentially the same with the tools used on lathes, except that their cutting speeds are measured by how fast the spinning material moves past the edge of the (stationary) turning tool.

How to Determine Cutting Speed?

Cutting speed formula

Cutting speed (V)=π X D X S / 1000

π=The circular constant

D=Diameter of (the workpiece for turning machine/ the tool for milling machine)

S=Spindle Speed

Factors should be considered

The proper cutting speed for a given job depends upon the hardness of the material being machined, the material of the tool bit, and how much feed and depth of cut is required.

The softer the work material, the faster the recommended cutting speed. The hardness of the cutting tool material has a great deal to do with the recommended cutting speed. The harder the cutting tool material, the faster the cutting speed. The softer the cutting tool material, the slower the recommended cutting speed.

What is Feed rate?

Feed rate is defined as tool’s distance travelled during one spindle revolution.

Feed rate formula

That value is determined by another calculation: the recommended chip load per tooth X the number of the teeth X spindle rpm. On a four-flute end mill with a 0.005-inch chip load running at 2,000 rpm, that comes out a sedate 40 IPM(inches per minute) feed rate.

Factors should be considered, feed rate is dependent on the:

- Type/size of the tool

- Surface finish desired

- Power available at the spindle

- Rigidity of the machine and tooling setup

- Strength of the work piece set up

- Characteristics of the material being cut, chip flow depends on material type and feed rate

What is depth of cutt

Depth of Cut

It is the total amount of metal removed per pass of the cutting tool. It is expressed in mm. It can vary and depending upon the type of tool and work material. Mathematically, it is half of difference of diameters.

Depth of cut (t) = D-d/2 mm