Precision 5-Aixs CNC Milling — Fast, Accurate, and Versatile

High-quality machining for prototypes, functional parts, and production runs. Tolerances up to ±0.003mm (±0.0001in).

What is CNC Milling?

CNC (Computer Numerical Control) milling is a subtractive manufacturing process where material is removed from a solid block using rotating cutting tools. It produces high-precision parts with tight tolerances and excellent surface finishes. CNC milling is suitable for metals, plastics, composites, and more.

- High precision and tight tolerances

- Multi-axis machining (3, 4, or 5-axis)

- Suitable for prototypes, small-batch, or production parts

- Wide material compatibility

- Fast turnaround and consistent quality

CNC Milling Materials

We offer over 60+ CNC Machining materials and a wide range of surface finishes, and we also support customized materials for special projects.

Surface Finishes For Metal Casted Parts

Improve durability and performance with a selection of finishesAnodizing

Black Oxide

Polishing

Tumbling

Brushing + Electropolishing

Smooth Machining

Electroless Nickel Plating

Sandblasting / Shot Peening

Part Marking / Laser Engraving

Color Matching / Painting

Heat Treatment

Insert, Thread Tapping

Vapor Polishing

Why IN3DTEC For CNC Milling

From idea to production, we help you get there faster.

100+ Industrial Printers

– HAAS, FANUC, BROTHER & more.

Maximum Part Size

– As large as 960mm cubic/ 37.8inch cubic.

Broad Material Options

– 60+ Plastics, metals, composites, and custom materials.

Fast Turnaround

– Speed without compromising quality.

Expert Support

– Design optimization & engineering guidance.

Strict Quality Control

– Certified processes, reliable results.

Scalable Production

– From prototypes to mass production.

Global Service

– Worldwide delivery & logistics support.

Competitive Pricing

– Flexible and cost-effective solutions.

Walls are too thin, minimum recommended thickness value is 1.0

Show thin walls

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

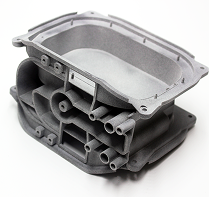

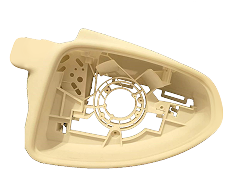

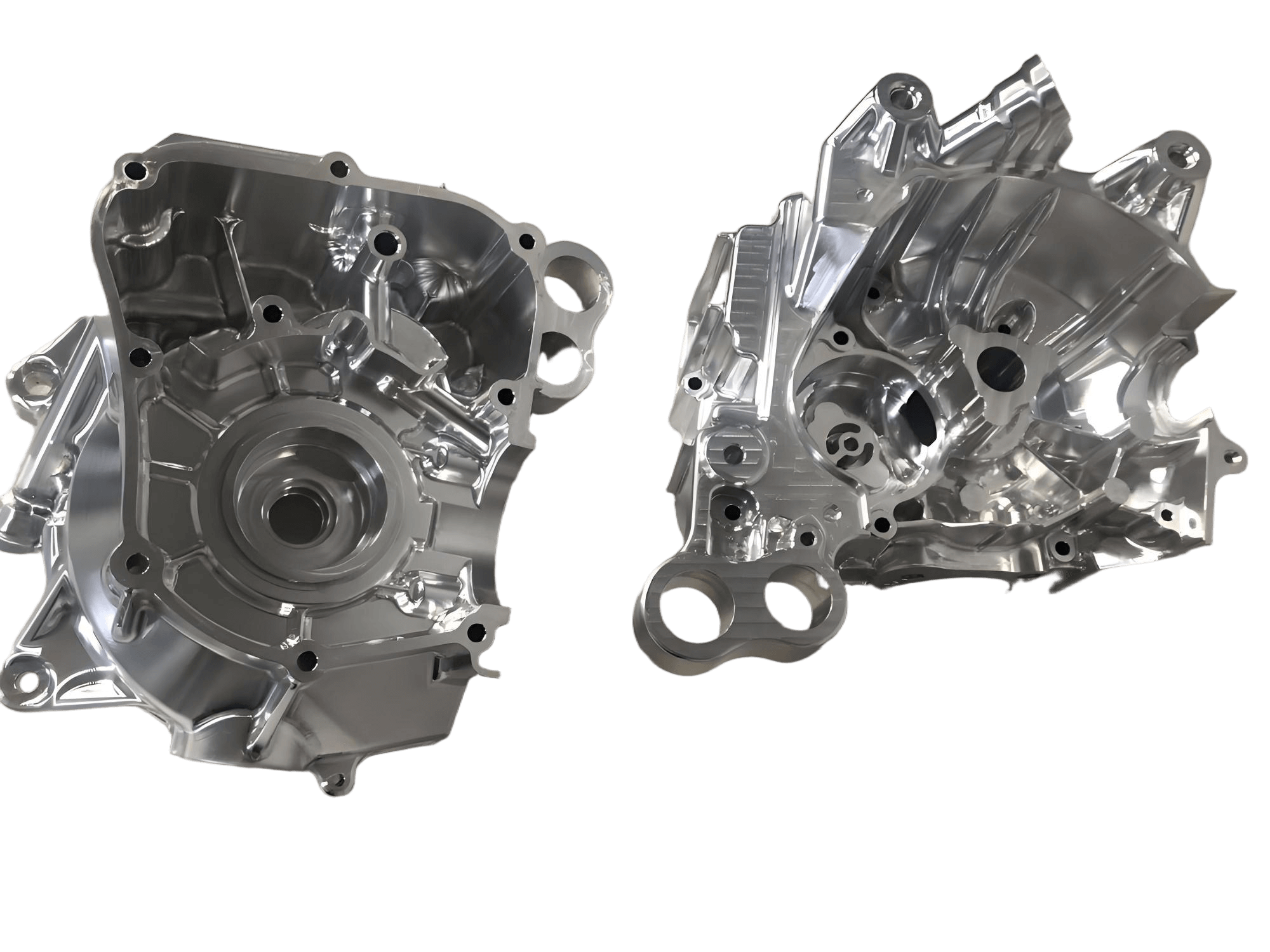

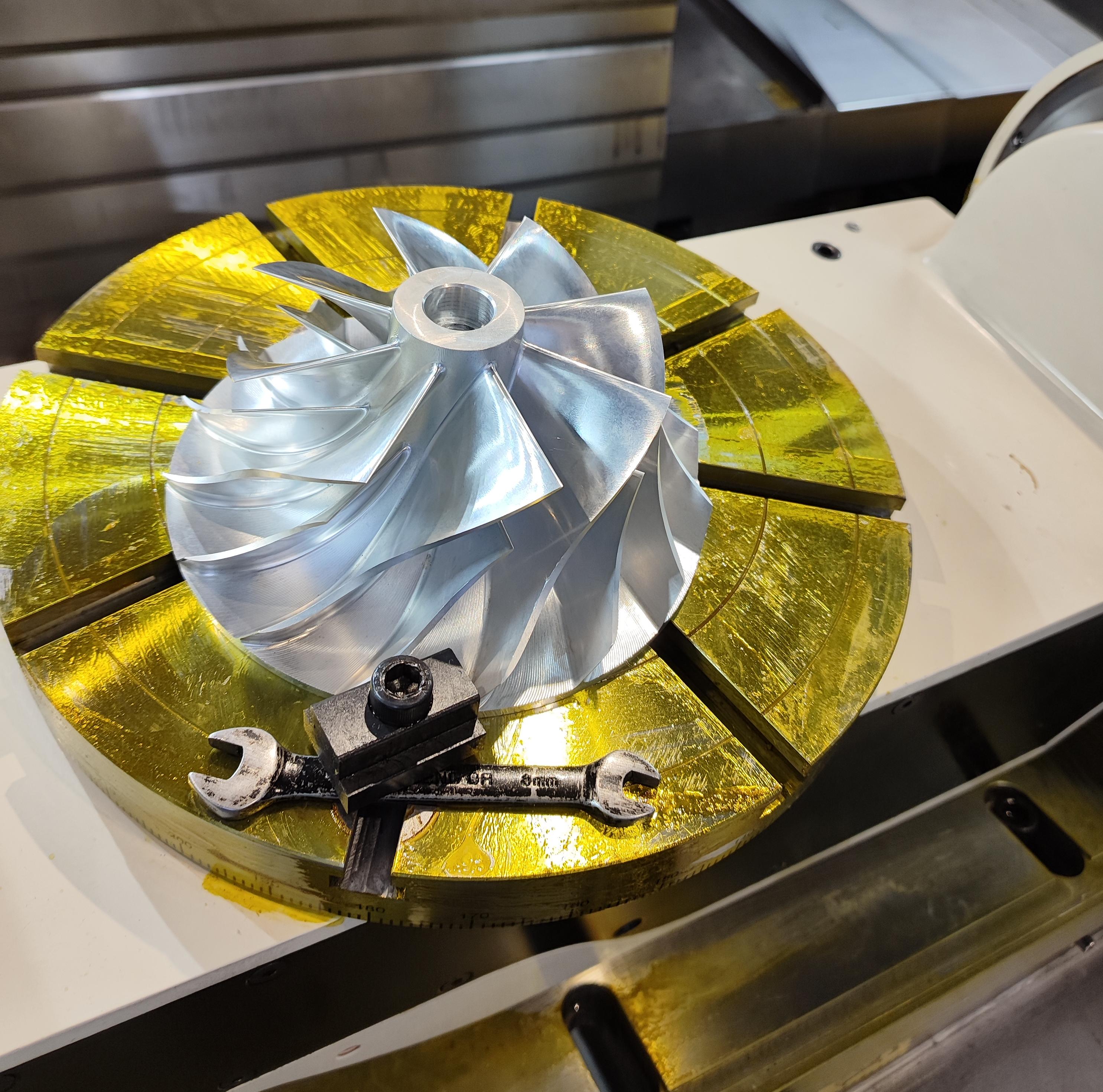

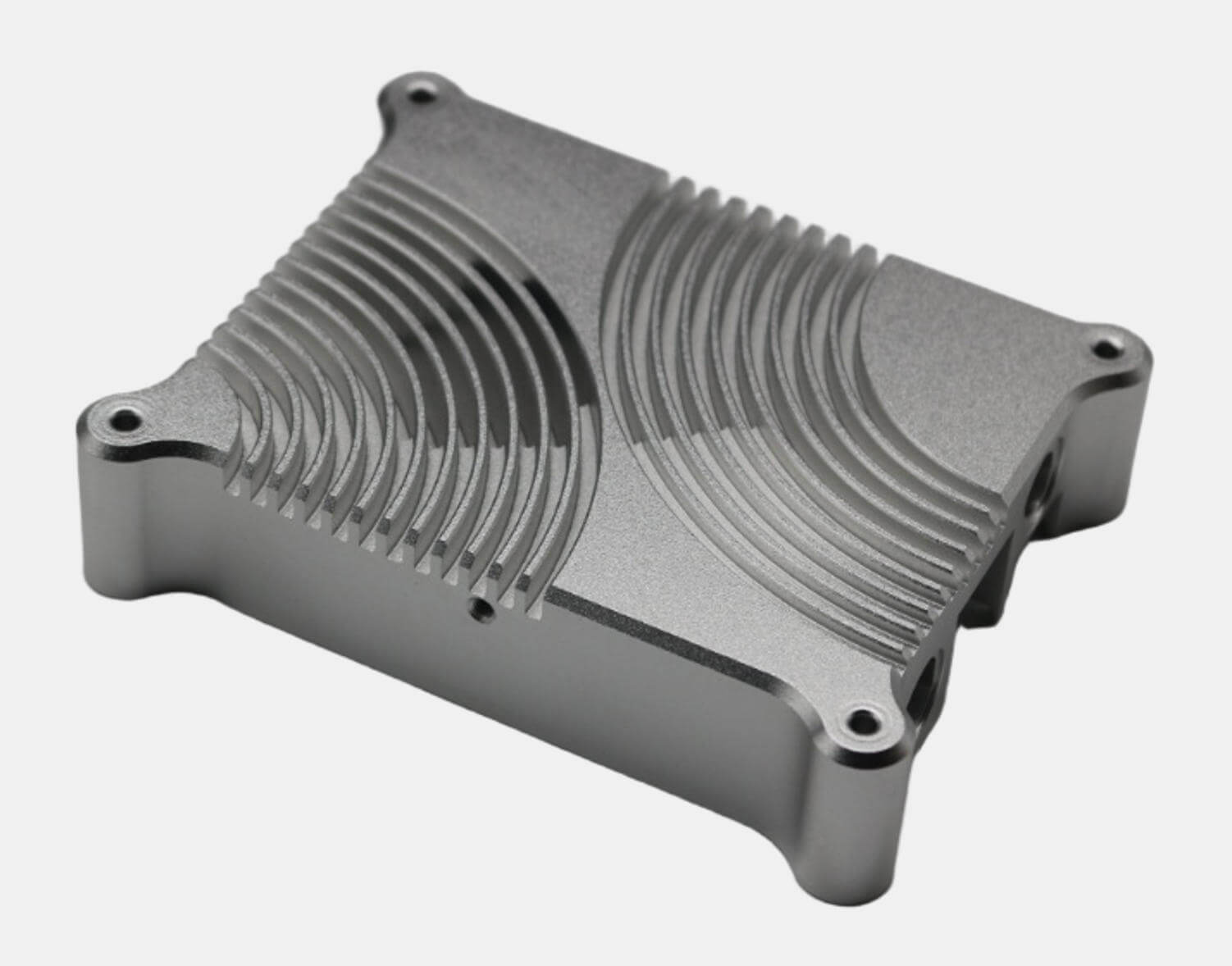

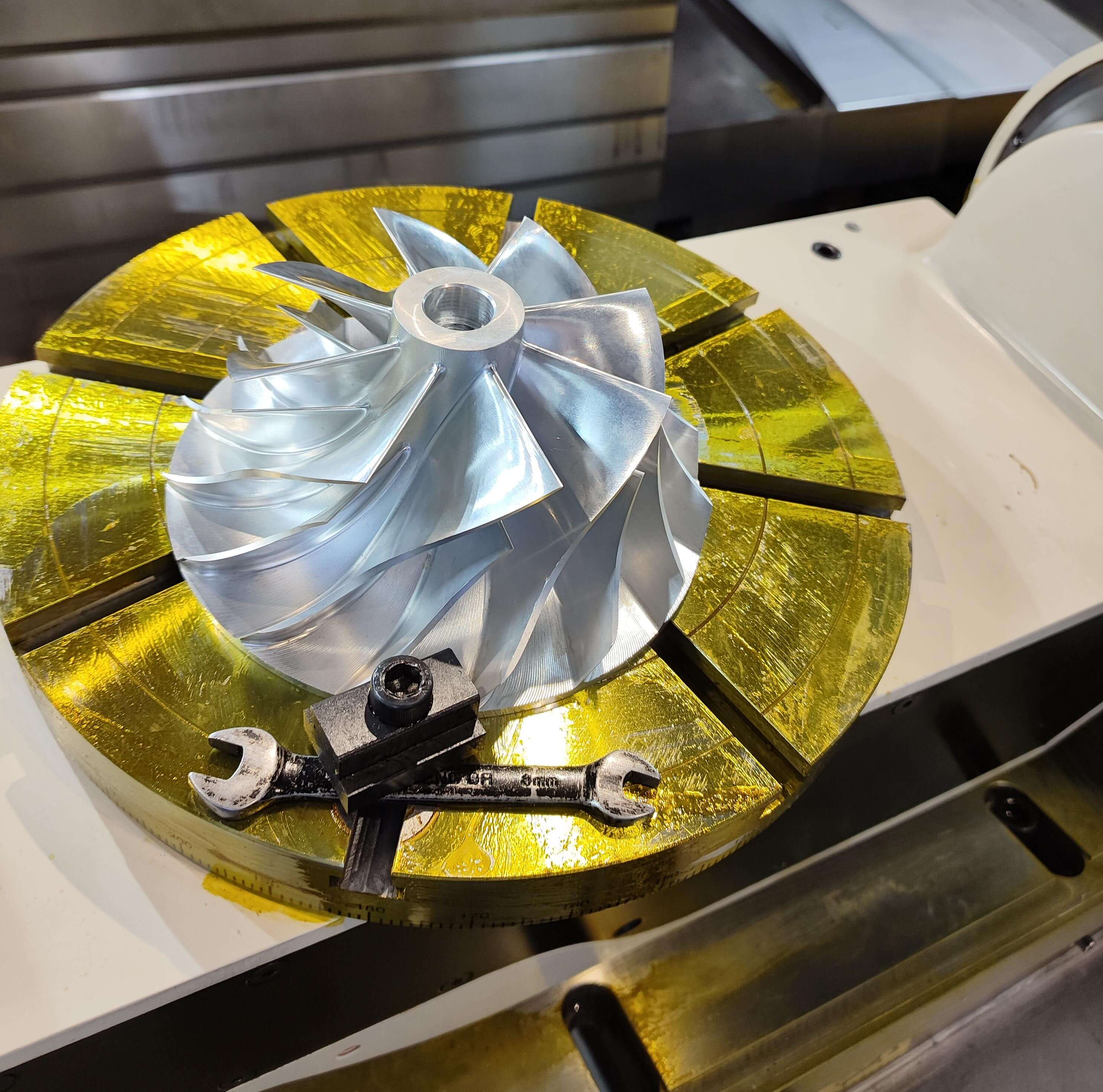

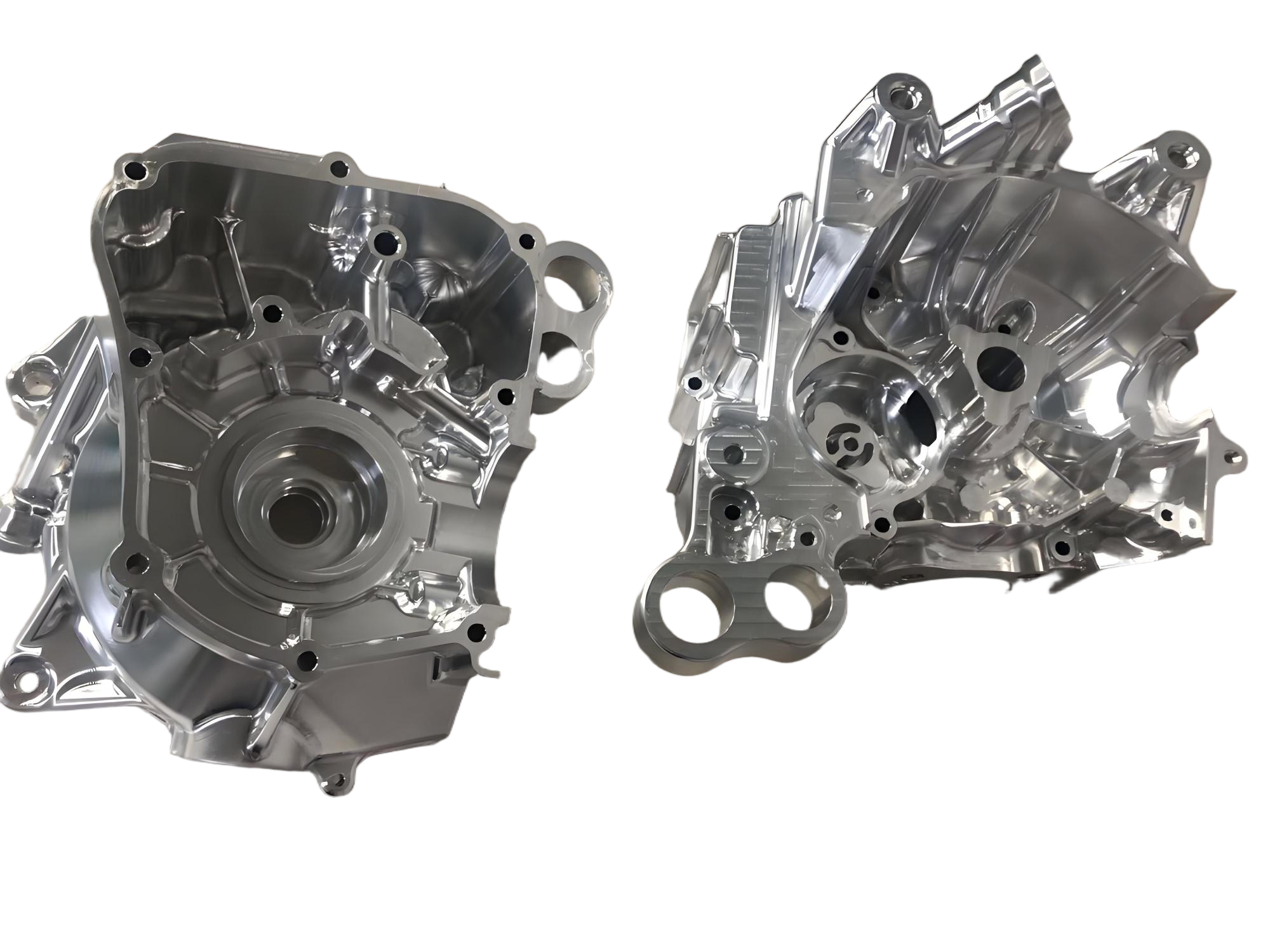

Gallery Of 3D Prints

How CNC Milling Works?

CAD & CAM Preparation – Import CAD model and generate toolpaths using CAM software.

Setup Material – Secure the workpiece on the milling machine.

Milling – Rotating cutters remove material layer by layer.

Quality Check – Inspect dimensions and tolerances during and after machining.

Finishing – Optional polishing, coating, or secondary machining operations.

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Put your Parts into Production Now

Manufacturing Resources

View All

CNC Machining Basics You Need to Know

CNC machining has been with us for a long time, but few people are aware of this technology. Have you wondered after seeing zigzag geometries and appealing designs on automobiles and equipment? Do you think technology is behind these artifacts?

Read MoreQ & A

A: Max. 1000mm cubic

A: Lead times range from 3–7 days for prototypes, longer for complex or high-volume orders.

A: STEP, IGES, and native CAD files are generally supported for CNC milling.

A: ±0.003mm (±0.0001in).

A: Yes, please click Get Instant Quote and see price within seconds

A: Yes, CNC milling is excellent for prototypes and low-volume runs due to flexibility and no tooling cost.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文