From Prototype to Production: Empowering Robotics with High-Precision Manufacturing

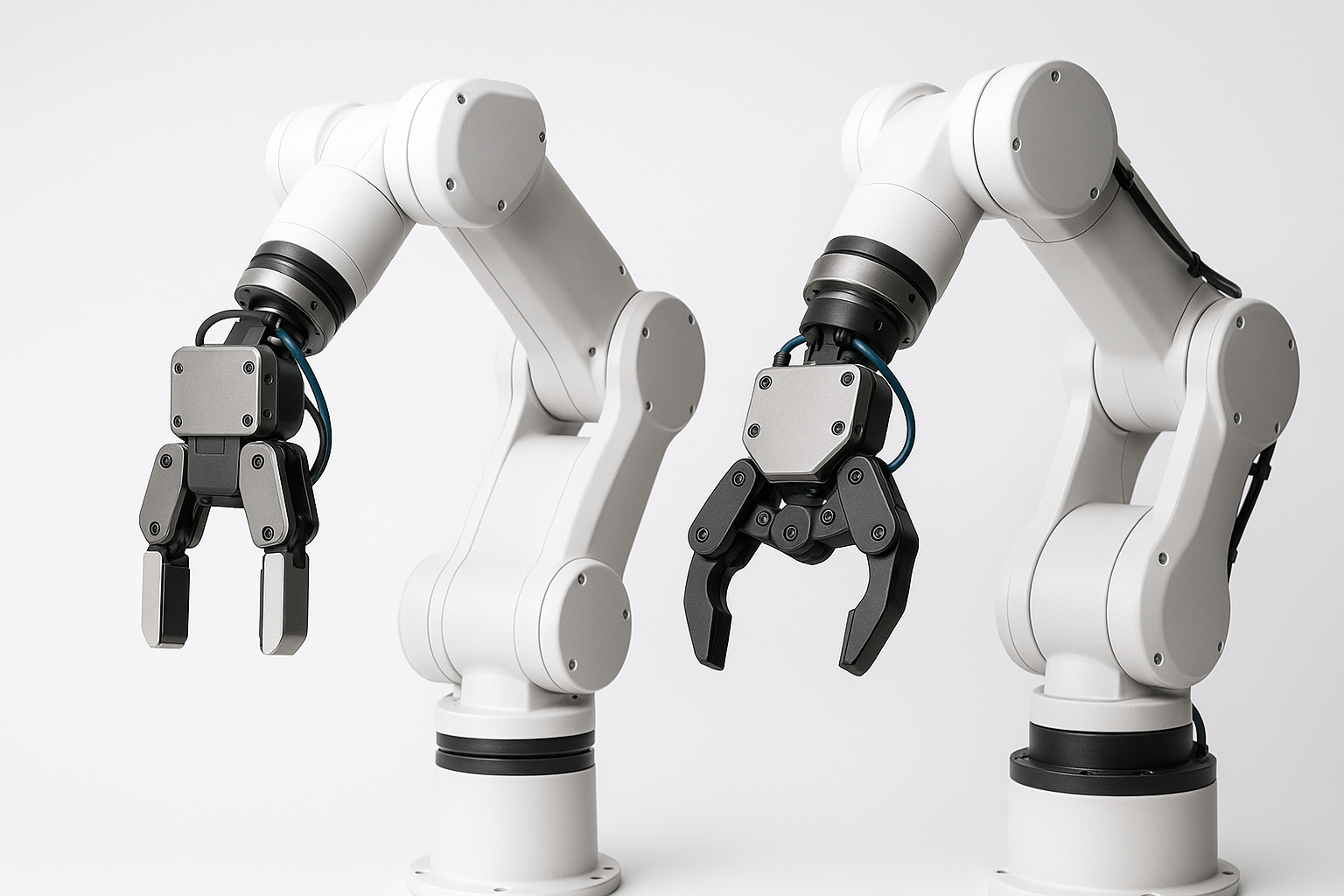

From lightweight prototypes to production-ready components, IN3DTEC delivers the precision, strength, and speed required for cutting-edge robotics.

All uploads are in confidential, view our IP protection policy>>

How We Support the Design Agencies

Rapid Prototyping

Accelerate innovation with fast, high-precision prototyping. We help robotics engineers validate designs, test complex geometries, and optimize performance using 3D printing, CNC, molding, and composite materials.

Low-Volume Production

We provide low-volume manufacturing with consistent quality. Whether it’s lightweight metal parts, custom housings, or structural elements, our flexible production ensures cost efficiency without compromising performance.

On-demand & Mass Production

Scale your Robotics projects with confidence. From urgent replacement parts to large-batch runs, we delivers on-demand solutions and reliable mass production that meet your standards.

Maintenance, Repair, and Operations

On-demand custom parts for MRO applications, ensuring robotics equipment stays up and running without interruption.

Why choose us for Robotics Parts

From idea to production, we help you get there faster.

Various Of Materials

– We provide over 160+ materials, including plastics, metals, composites, and high-performance polymers. Our wide selection ensures you get the right material for every project.

High Precision Parts

– Equipped with sharp edge equipments, we achieve tolerances up to ±0.02mm. This ensures every part meets strict dimensional accuracy and functional requirements.

Quick Turnaround

– Speed matters in Robotics. With our streamlined processes , we provide rapid prototyping and fast delivery, helping you accelerate development cycles and stay ahead of deadlines.

IN3DTEC Manufacturing Capabilities To Meet Your Needs

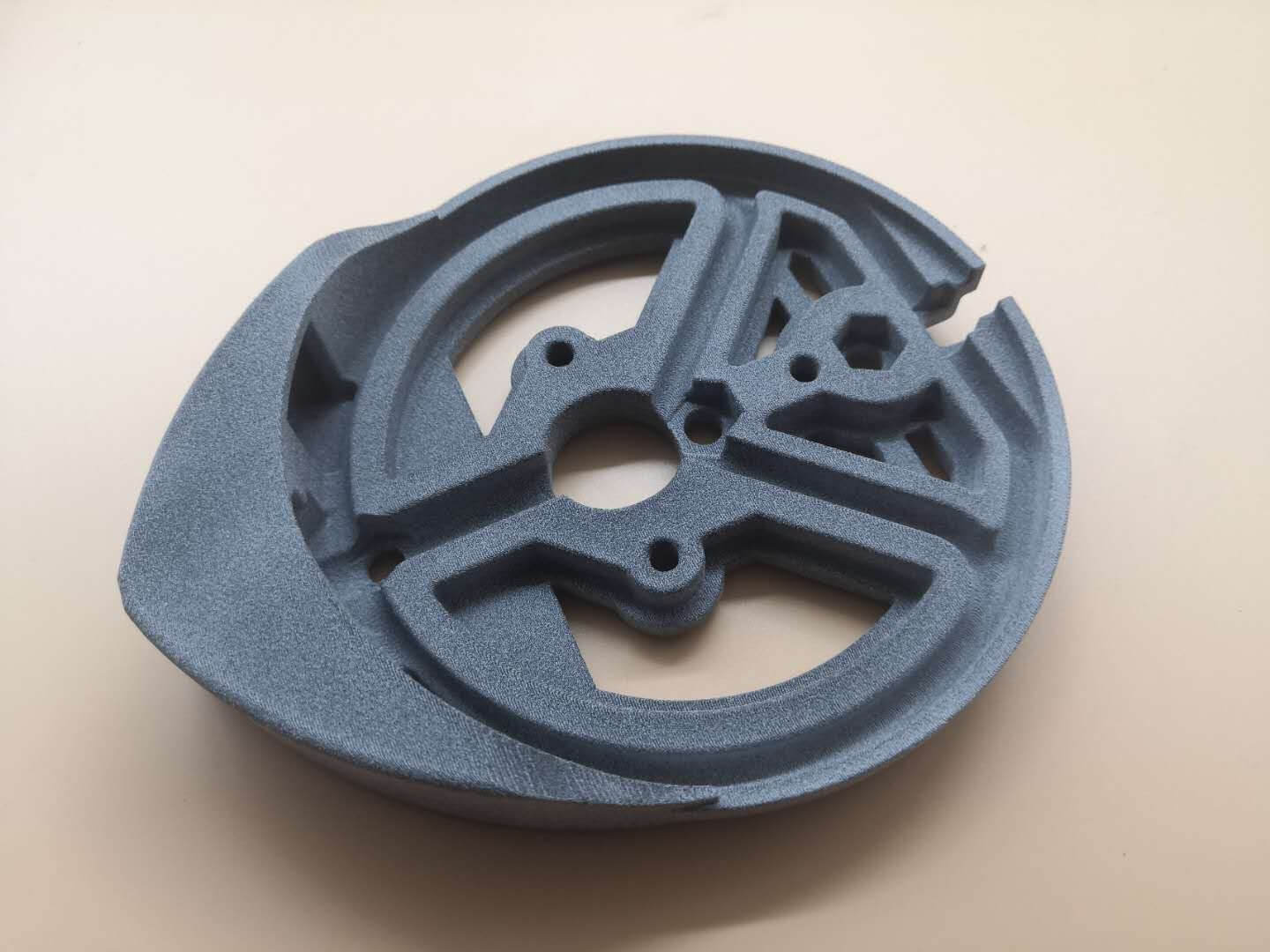

3D Printing

FDM, SLM, SLA, SLS, DLP, MJF, Ceramic, Sand printing & Casting, Colorful parts. As fast as one day.

CNC Machining

CNC Milling ( 3,4, 5 axis) CNC Turning, EDM. up to ±0.003mm (±0.0001in)

Injection Molding

Insert Molding, Over molding, Low volume Injection Molding. No MOQ, from 1 to 1M parts.

Vacuum Casting/Urethane Casting

ABS, PP, Nylon, PC, TPU/Rubber, Transparent. Best alternative to injection molding for low volume run.

3D Scanning

Low cost to create a CAD file in 1-3 days.The final format be delivered in STL or STEP format.

Carbon Fiber Composites

High-strength, lightweight for durable, precise, and performance-driven engineering applications.

Die Casting

Aluminum/Zinc/Magnesium/Copper. 0.03in walls, 1000+ unit batches.

Sheet Metal

Expert laser cutting, bending, welding & stamping. Fast, highly precise.

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

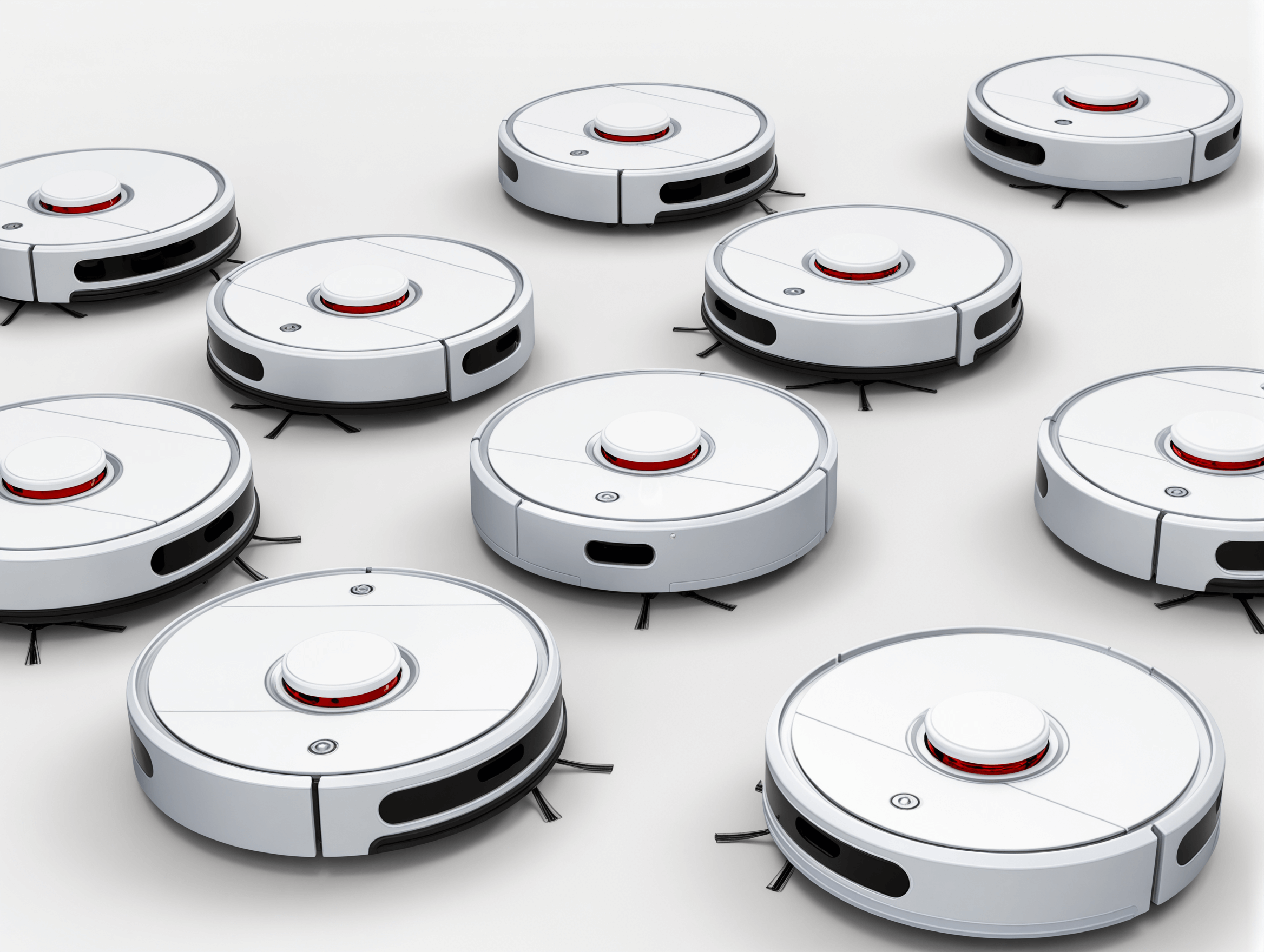

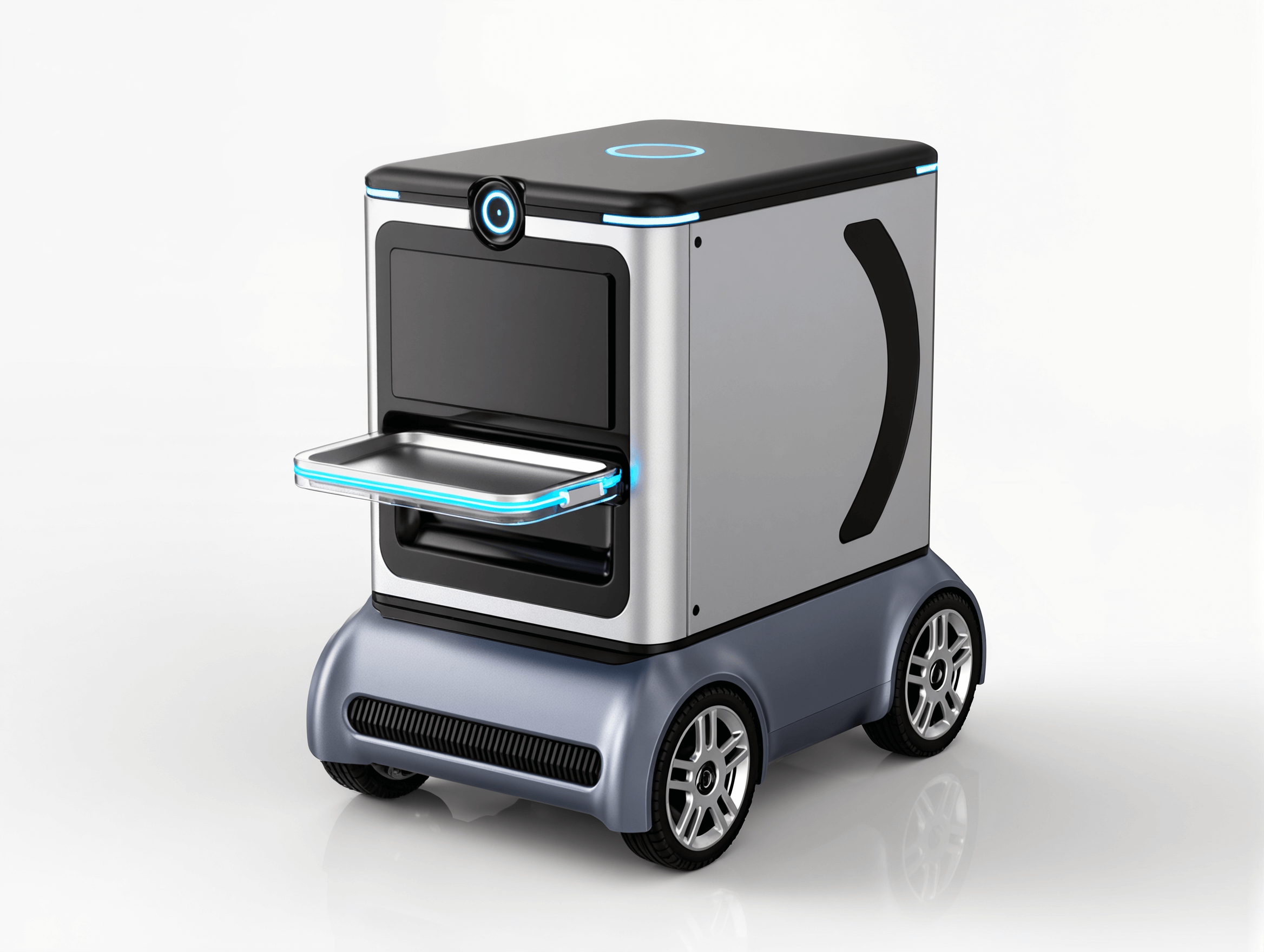

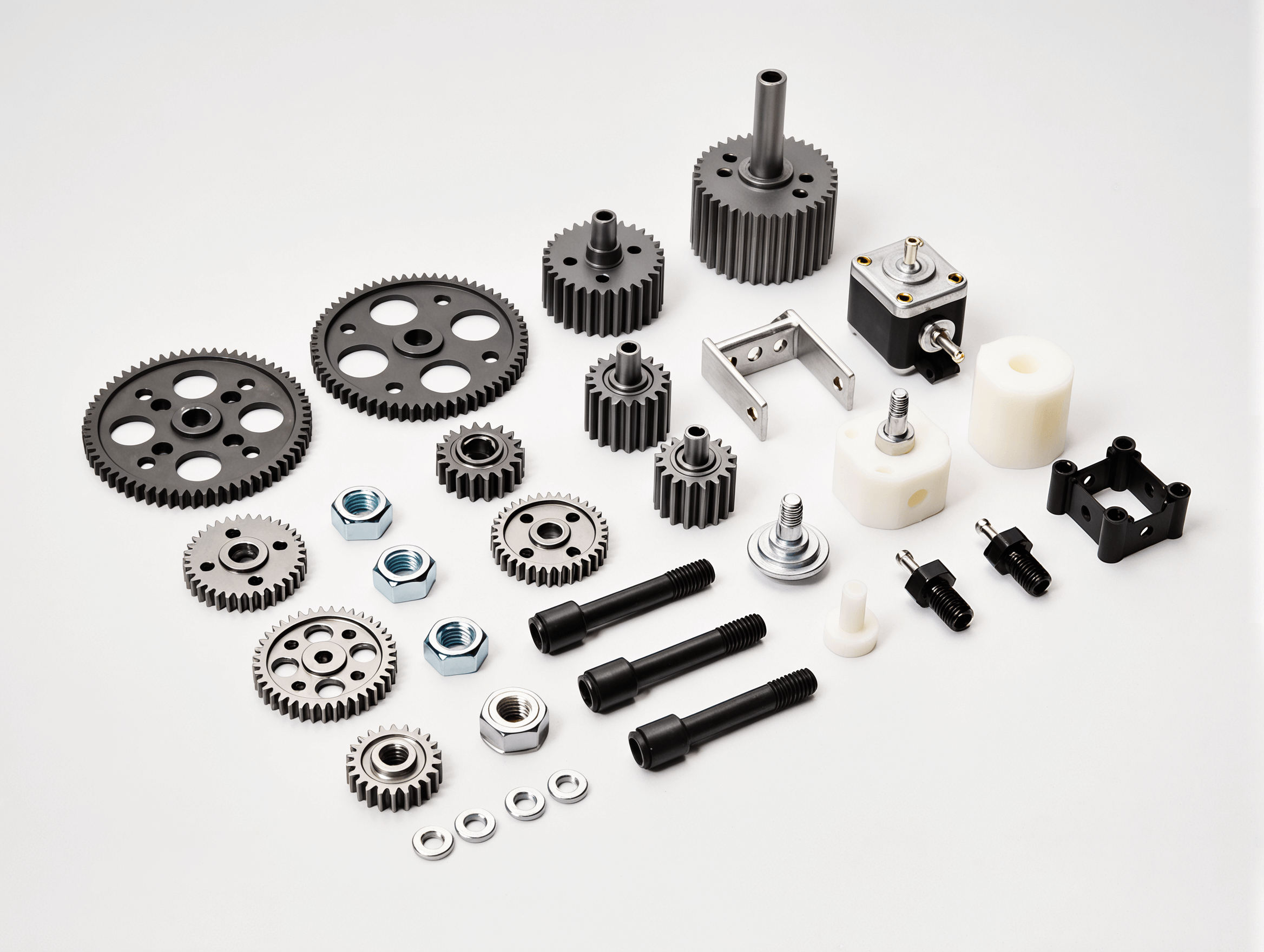

Gallery Of Projects We Made

Materials & Surface Finishes

We offer over 160+ materials and a wide range of surface finishes, and we also support customized materials for special projects period.

Materials

Select from more than 160+Materials

Aluminum: 5052, 6061, 7075, AlSi10Mg 2024-T351

Stainless Steel: 304, 316, 17-4PH, 420,4140, A36,1045

Titanium : Ti Grade 1, 2, 5

Copper, Brass, Bronze, Tool Steel, Magnesium Alloys,Co_Cr, Inconel 718, Inconel 625, high strength steel

Thermoplastics: ABS, Nylon (PA6, PA66, PA12, Nylon-CF, Nylon-GF), Polycarbonate (PC),POM (Delrin, Acetal)

PEEK, Ultem (PEI), PTFE (Teflon), HDPE, PP (Polypropylene)

Carbon Fiber Reinforced Composites,Glass Fiber Reinforced Composites

Read more

Surface Finishes

Improve durability and performance with a selection

of finishes

Anodizing

Polishing

Tumbling

Brushing + Electropolishing

Smooth machining

Electroless nickel plating

Sandblasting/Shot Peening

Part marking/Laser engraving

Color Matching/Painting/UV Coating

Heat treatment

Read MoreHow to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文