IN3DTEC Timeline (2014–2024)

-

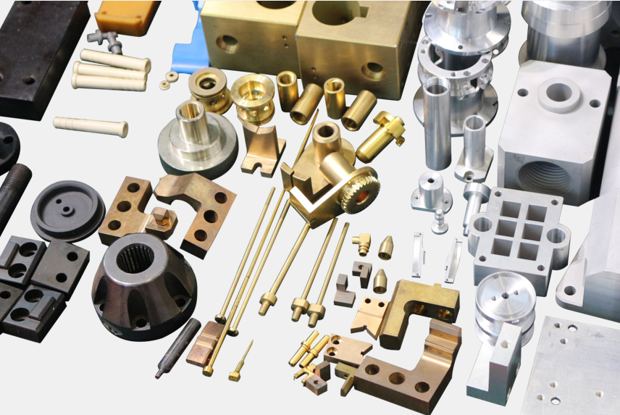

2014Launched locally, offering metal and high-performance plastic 3D printing and 3D scanning services.

-

2015Core technical team formed; began prototyping with metal/plastic 3D printing, urethane casting, and scanning.

-

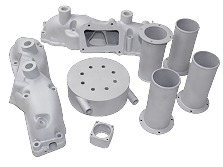

2016Added CNC machining and 5-axis milling for low-volume production.

-

2017Entered overseas markets and became supplier for ABB, Airbus, Danfoss, Leica, Philips, Ford, MIT, and Stanford University.

-

2018Officially established the IN3DTEC global brand for oversea market.

-

2019Introduced sheet metal and injection molding for on-demand production.

-

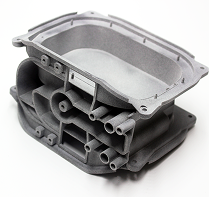

2020Expanded into die casting and custom carbon fiber; grew reach to 70+ countries across Europe, North America, and APAC.

-

2021Broadened 3D printing to ceramic, sand printing & metal casting, soft elastomers, multi-colors, and medical applications; upgraded production and inspection systems.

-

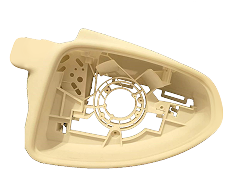

2022Rolled out surface finishing for automotive, aerospace, robotics, medical, and industrial applications; launched Online Quoting System.

-

2023Became a full-scale one-stop shop for prototype to mass production, offering comprehensive manufacturing and finishing services.

-

2024Now serve ¼ of Fortune 500 companies, deliver to 89 countries, support 10,000+ clients with 160+ materials, and offer more than 25+ surface finishe options.

Our Customers

In order to meet different market needs, we expand our offerings to service Aerospace, Automotive, Education, Electricals, Jigs & Fixtures, Medical, Oil & Gas, Transportation, and more. The opinions of our customers serve as the cornerstones for benchmarking our performance which we are committed to continuously improving.

Manufacturing Resources

View All

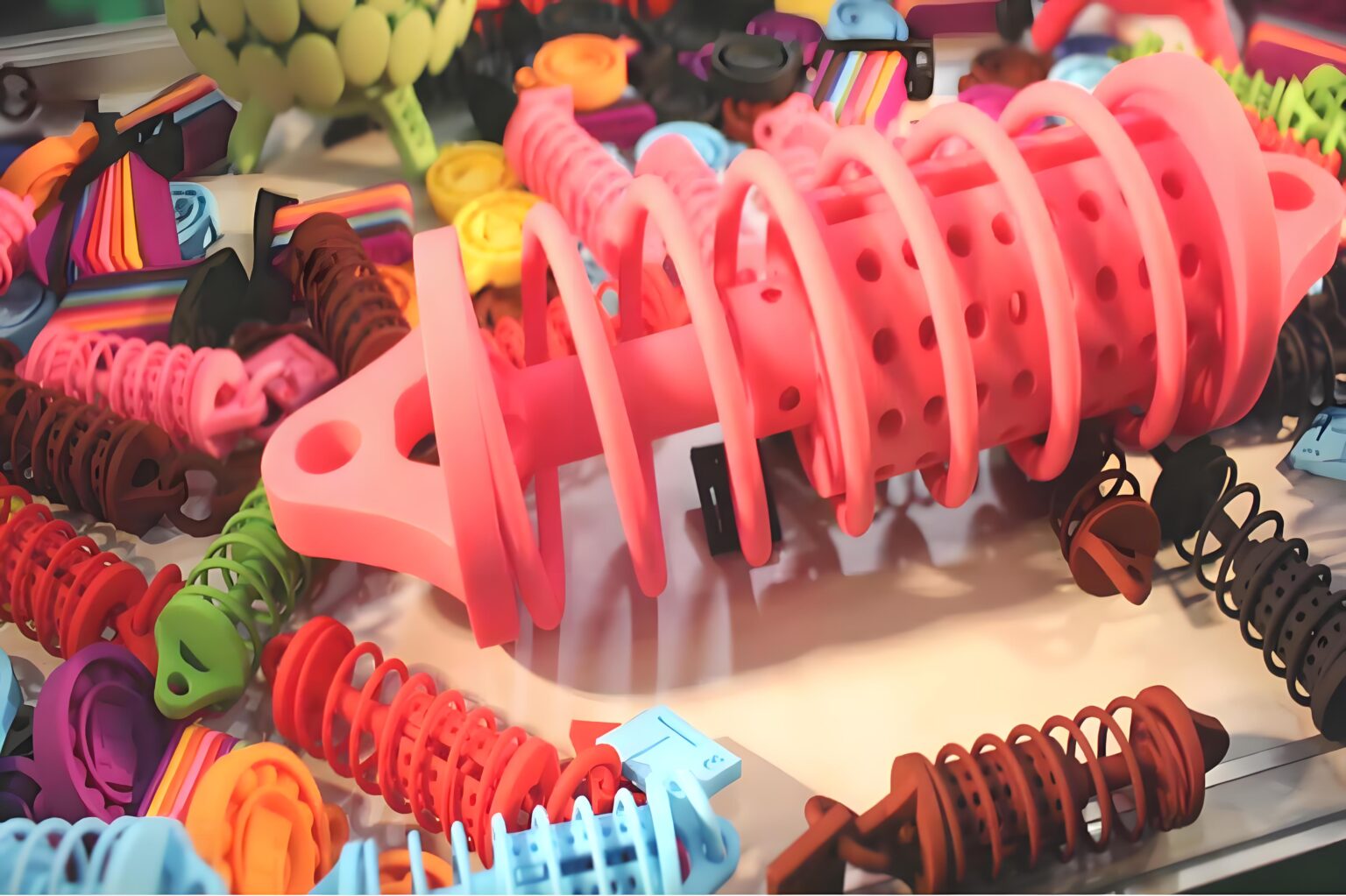

Cool & Useful Things, ideas to 3D Print for November

100 cool & useful 3D Print Projects, Ideas You’ll Love In the ever-evolving world of technology, 3D printing stands out as a game-changing tool that

Read More

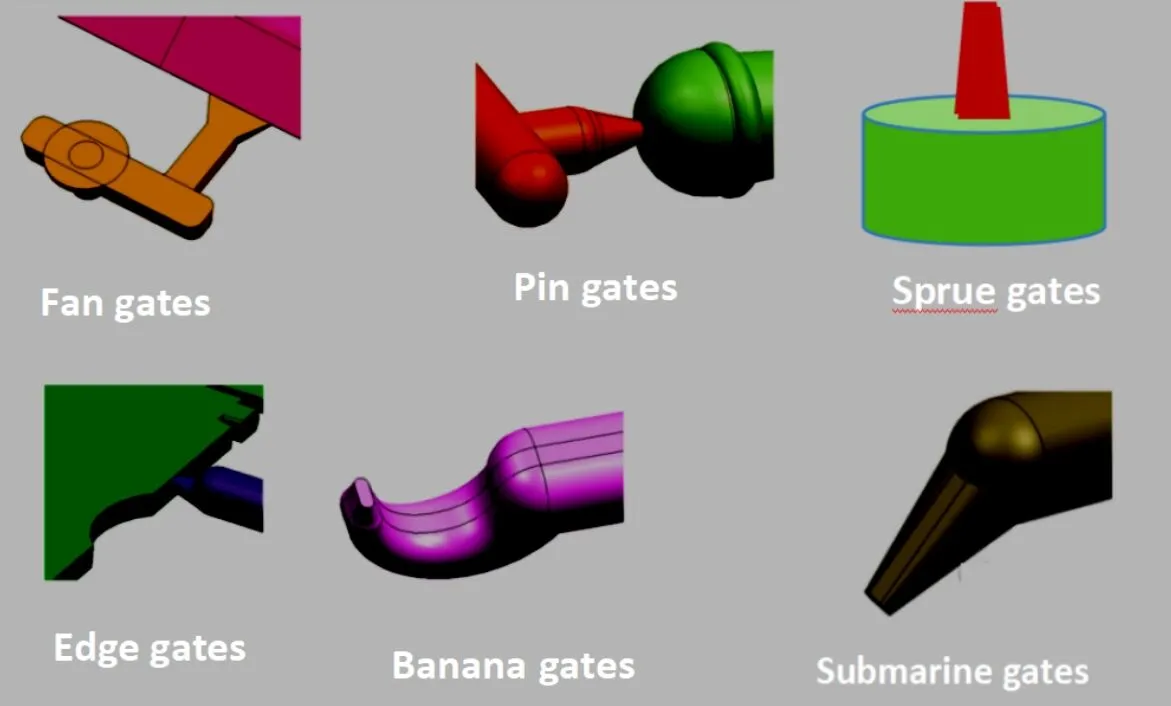

A Comprehensive Guide to Injection Molding Gates

Comprehensive Guide to Injection Molding Gates Introduction: Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. A

Read More

Selective Laser Sintering (SLS) Material Selection Guide for Low Volume Production

Selective Laser Sintering (SLS) Material Selection Guide for Low Volume Production In recent years, Selective Laser Sintering (SLS) has emerged as one of the most

Read More

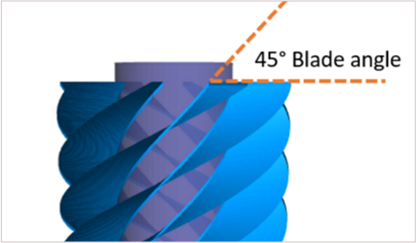

How to design parts for metal 3D Printing

With the gradual popularization of 3D printing, more and more users will directly consider metal printing when producing products, so how to design a product suitable for metal printing? Is anything we should pay attention to? IN3DTEC will analyze the des

Read More

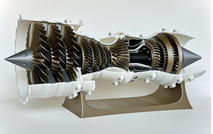

Modernizing Metal Casting with Sand 3D Printing

Modernizing Metal Casting with Sand 3D Printing for centuries, metal casting has been a trusted method to produce strong, complex parts across industries—from automotive and

Read MoreFrom Quote To Delivery

Everything You Need in One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving your time and ensuring smoother part production.

No Minimum Quantity

AI-Powered DFM Analysis

Online Order Management

Flexible Lead Time & Shipping Options

Walls are too thin, minimum recommended thickness value is 1.0

Show thin walls

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文