High-Precision Sheet Metal Fabrication for Prototypes and Production

From laser cutting to complex assemblies, we provide fast, accurate, and cost-effective sheet metal parts tailored to your industry needs.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat metal sheets into functional parts or products through cutting, bending, punching, stamping, and assembling. It is widely used across industries such as automotive, aerospace, electronics, medical, robotics, and consumer products. By combining precision engineering with a wide range of metals—such as aluminum, stainless steel, copper, and galvanized steel—sheet metal fabrication offers flexible solutions for both prototyping and mass production.

Cost-effective for prototypes and small production runs

Cost-effective for prototypes and small production runs

High Strength & Durability

High Strength & Durability

Precision & Consistency

Precision & Consistency

Rapid turnaround, ideal for design validation

Rapid turnaround, ideal for design validation

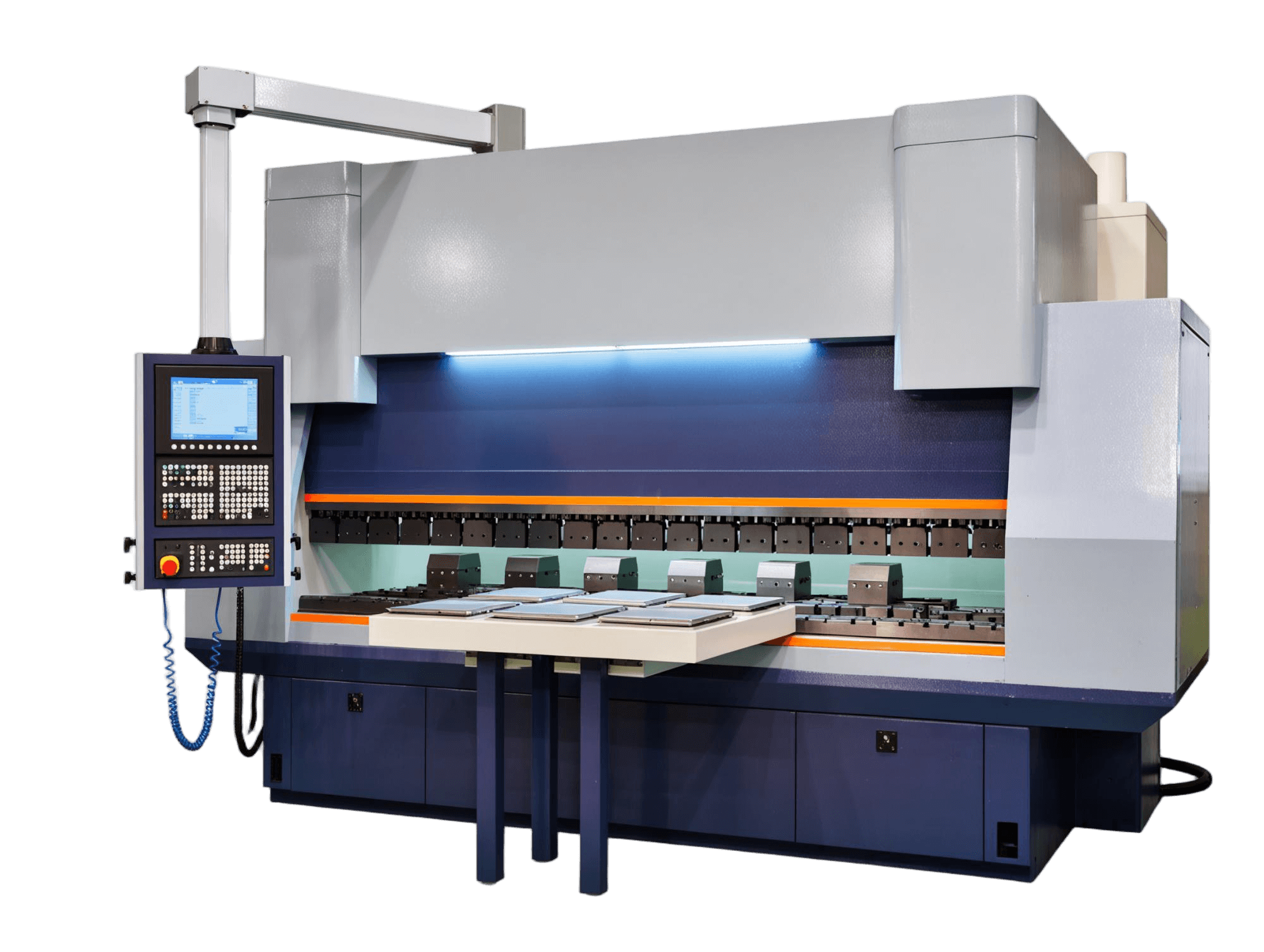

Our 3D Sheet Metal Fabrication Capabilities

Comprehensive sheet metal capabilities covering prototypes to production, with diverse materials, advanced processes, and fast turnaround.

One-Stop Service: From Rapid Prototyping to Mass Production

Taking your design from early-stage testing to full-scale production has never been easier. With our wide range of capabilities, we support your journey from prototyping to mass manufacturing. Let us be the backbone of your success and your trusted one-stop partner

Early Development: 3D Pritning, CNC Machining

– Quick-turn parts to validate fit, form, and function at the earliest design stages.

Mid Development: Sheet Metal Fabrication, Vacuum casting

– Highly representative models that balance aesthetics and functionality for deeper design validation.

Production: Die Casting, Metal Casting, Injection Molding, Vacuum Forming

– Production-quality parts ready for testing, bridge runs, and full-scale manufacturing.

Sheet Metal Fabrication Materials

We offer over 10+ sheet metal fabrication materials and a wide range of surface finishes, and we also support customized materials for special projects.

Why IN3DTEC for Your Sheet Metal Fabrication

From idea to production, we help you get there faster.

100,000 +

– Parts sheet metal parts produced each year.

89+

– Countries served

Broad Material Options

– 10+ metal materials

Fast Turnaround

– Speed without compromising quality.

Expert Support

– Design optimization & engineering guidance.

Strict Quality Control

– Certified processes, reliable results.

Scalable Production

– From prototypes to mass production

Global Service

– Worldwide delivery & logistics support.

Competitive Pricing

– Flexible and cost-effective solutions.

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

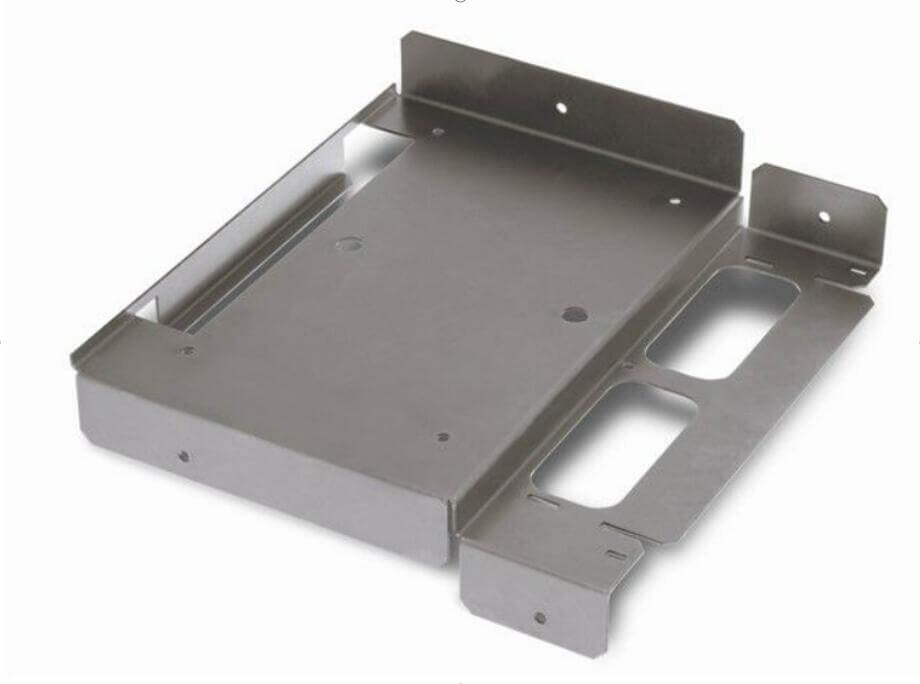

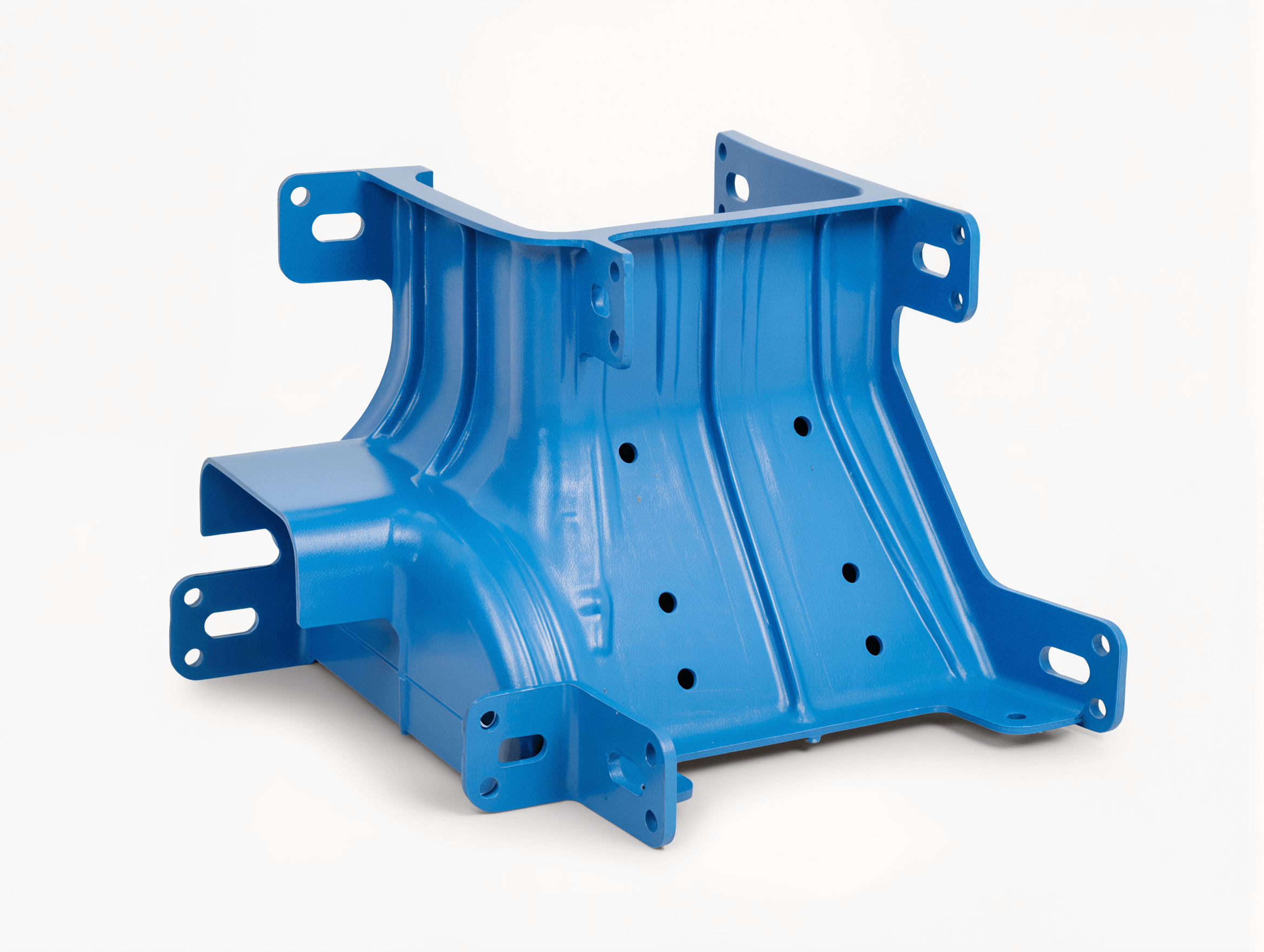

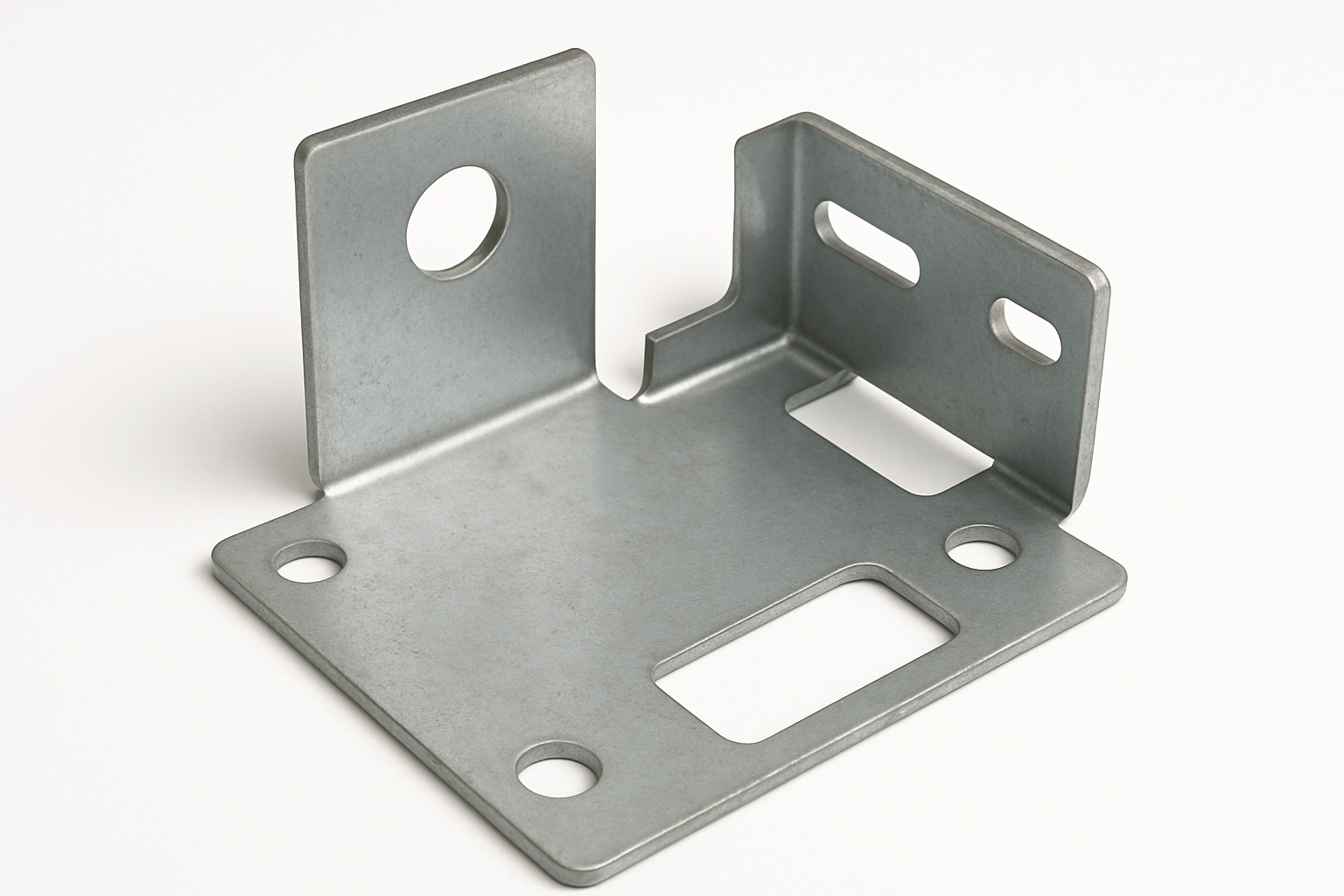

Applications: Our sheet metal parts are widely used in:

Electronics: enclosures, housings, EMI shielding

Medical: equipment housings, stainless steel fixtures

Consumer Goods: furniture components, decorative finishes

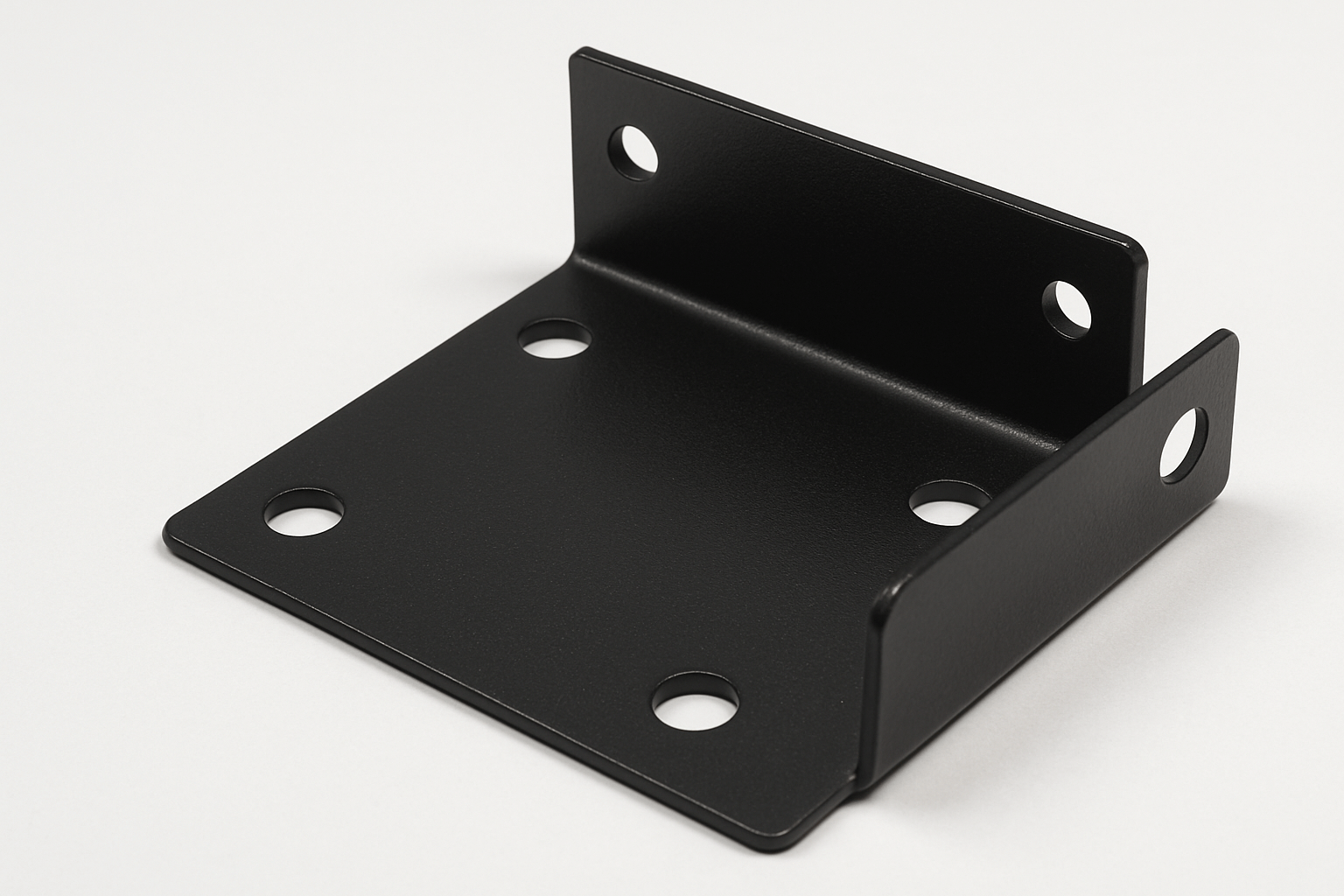

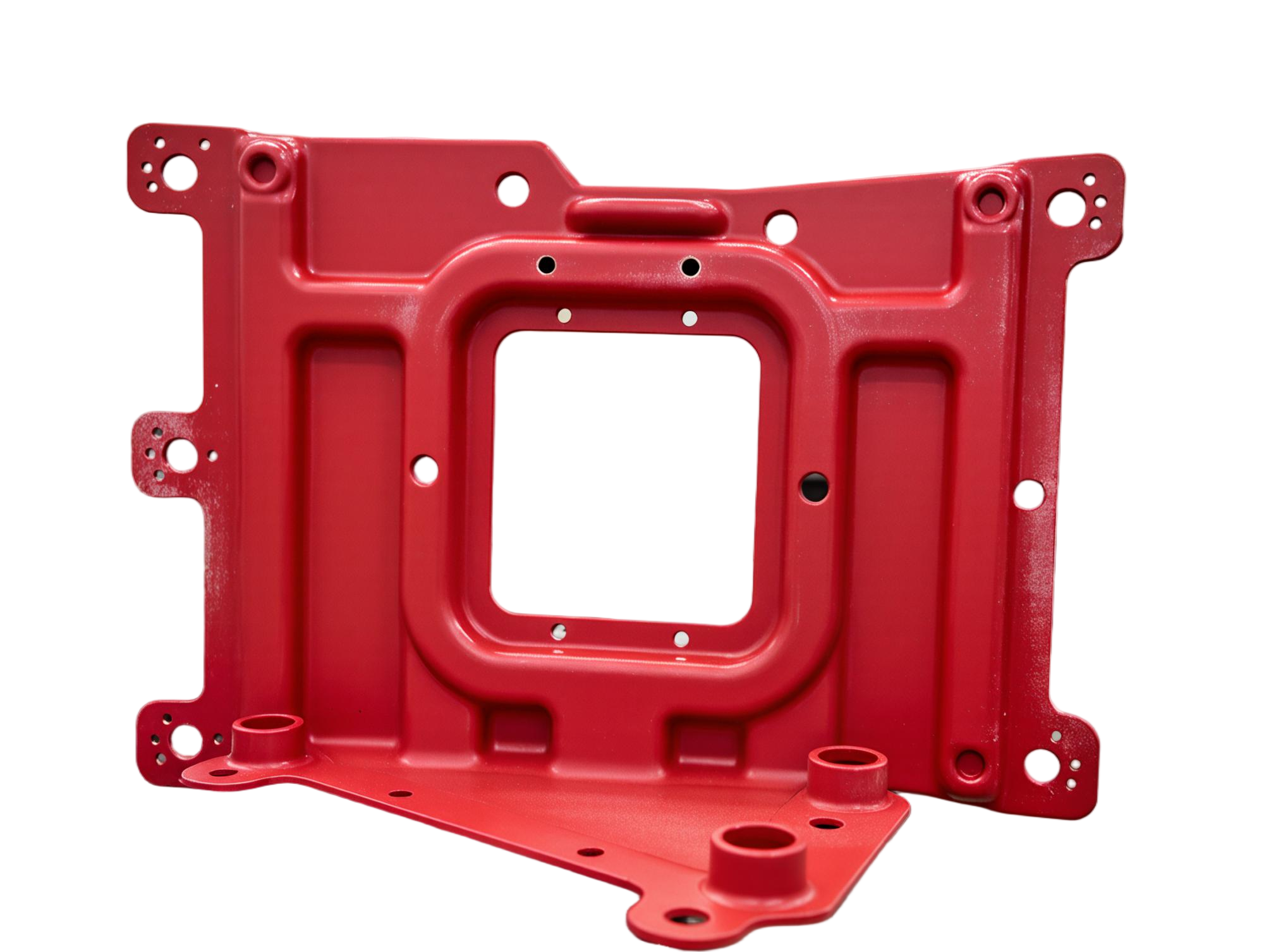

Automotive: brackets, chassis, interior panels

Aerospace: structural parts, ducts, mounts

Industrial: custom machinery covers, protective guards

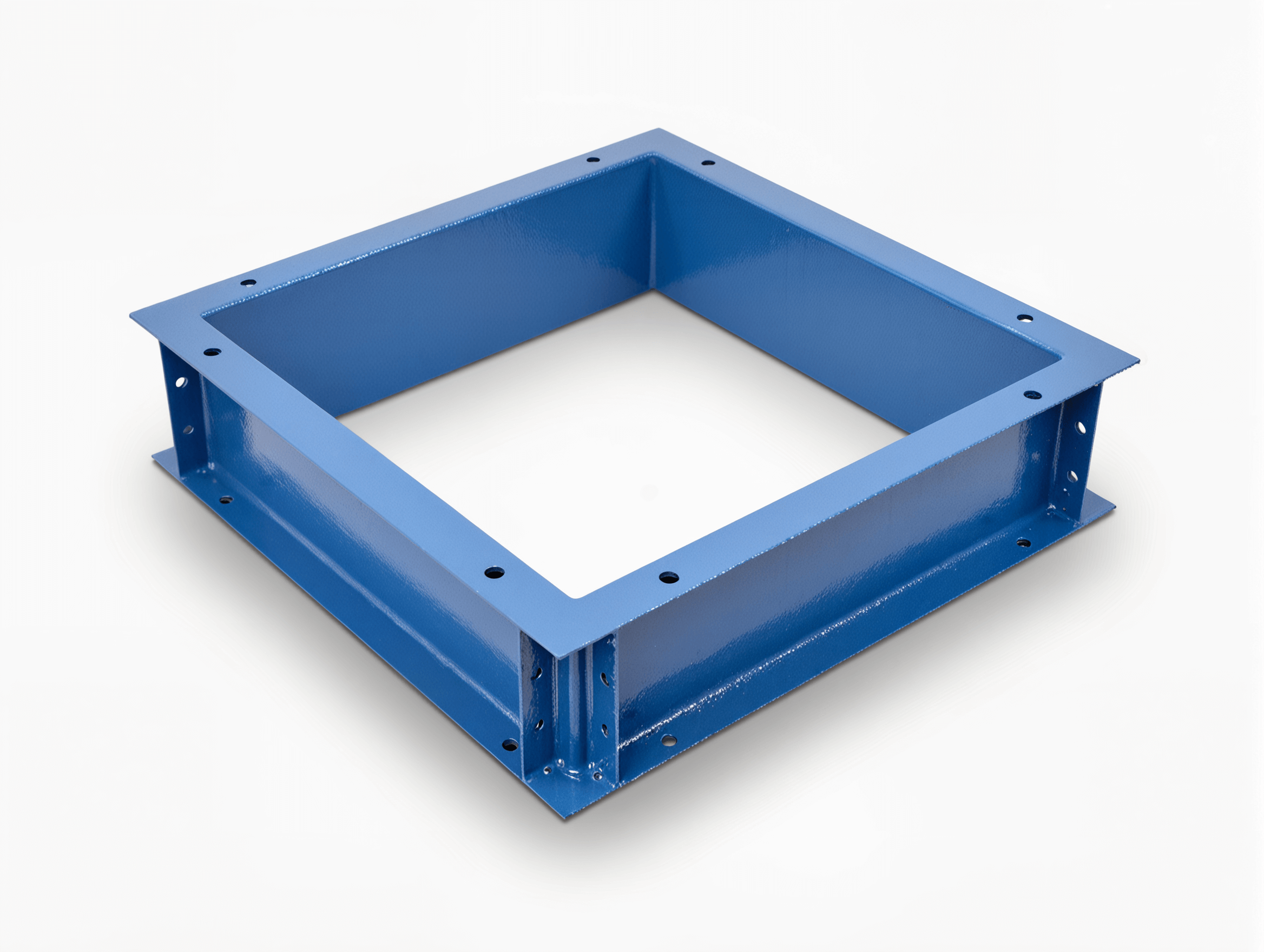

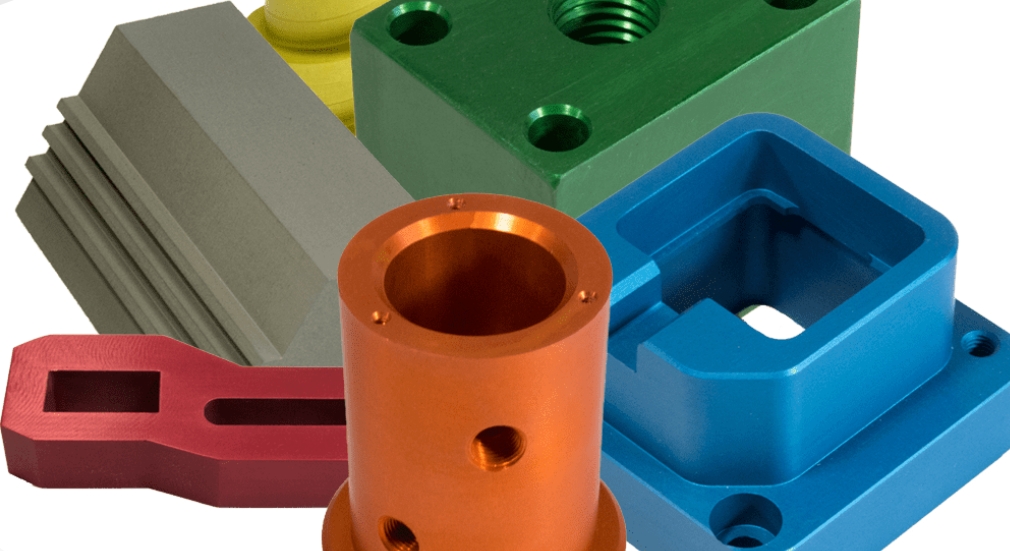

Gallery Of Sheet Metal Fabrication

Surface Finishes for Sheet Metal Fabrication

Improve durability and performance with a selection of finishes.

Anodizing

Black Oxide

Polishing

Tumbling

Brushing + Electropolishing

Smooth Machining

Electroless Nickel Plating

Sandblasting/Shot Peening

Part Marking/Laser Engraving

Color Matching/Painting

Heat Treatment

Thread Tapping

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Manufacturing Resources

View All

8 Things You Need to Know About Anodizing Aluminum

Aluminum is a versatile metal that is widely used in various industries for its lightweight, durable, and corrosion-resistant properties. One of the most popular surface treatment methods for aluminum is anodizing. Anodizing aluminum not only enhances its

Read More

Painting vs Powder Coating

When it comes to adding protective and decorative finishes to various surfaces, two popular methods have emerged: painting and powder coating. How to select the right one for your application?

Read More

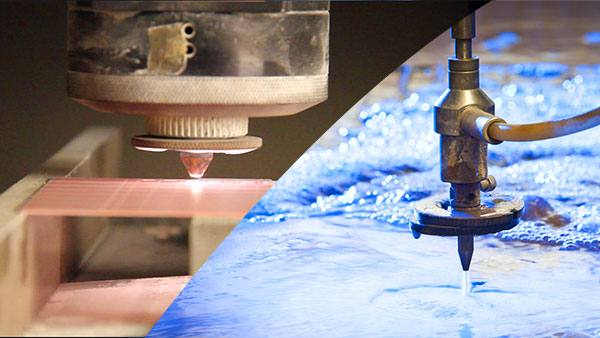

Laser Cutting vs. Waterjet Cutting – Key Differences

The differences between these two approaches don’t just lie in their methods but in their results and applications, too. When choosing between laser vs. waterjet cutting in your applications, consider the following:

Read More

Top 11 CNC Wood Carving/Cutting Machines in 2024

CNC (Computer Numerical Control) machines have revolutionized the woodworking industry, allowing for precise and intricate designs that would be challenging or impossible to achieve by hand. In 2024, the market is brimming with advanced CNC wood carving a

Read MoreQ & A

A: Typically 15–25 copies, depending on geometry and resin type.

A: Low cost, fast turnaround, excellent surface quality, and suitability for small-batch production.

A: Automotive, consumer electronics, medical devices, robotics, and industrial design prototyping.

A: Typically ±0.3 mm / 100 mm(Min. +/-0.3mm), depending on size and geometry.

A: Yes, both tinted and fully transparent finishes are available, with painting or polishing if needed.

A: Polyurethane resins simulating ABS, PP, PC, PMMA, Rubber (shore A 30–95), and transparent materials.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文