Carbon Fiber Composite Manufacturing Lightweight. Strong. Production-Ready.

Carbon fiber composites deliver unmatched strength-to-weight ratio, premium aesthetics, and durability.

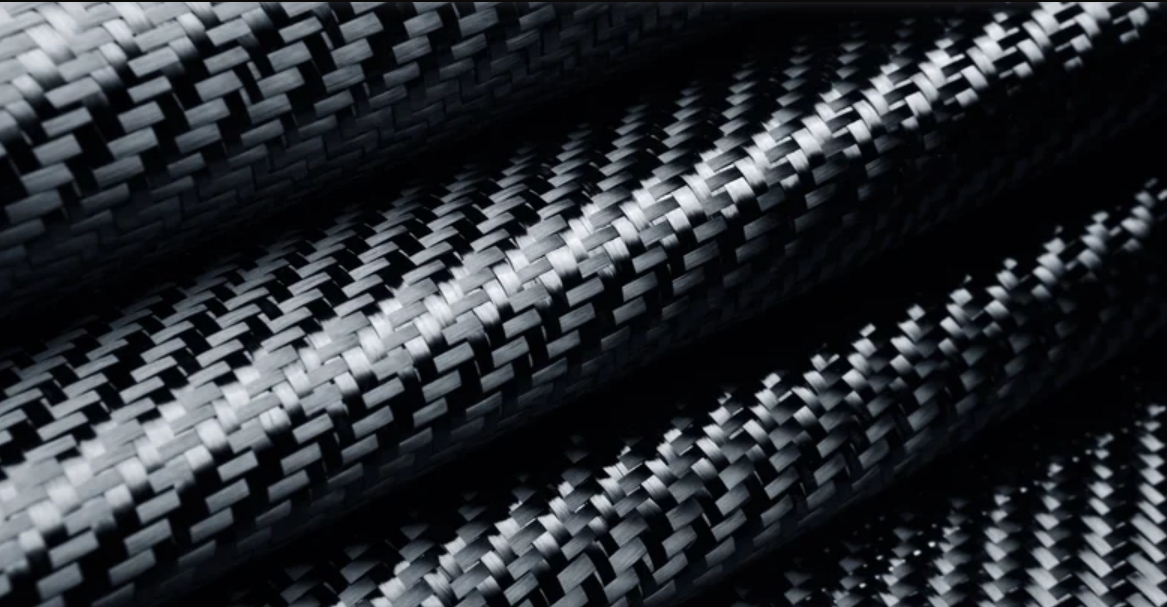

What is Carbon Fiber Composite?

Carbon Fiber Reinforced Polymer (CFRP) is made by combining carbon fibers with a polymer resin matrix (usually epoxy). Compared to metals, CFRP offers:

High strength & stiffness with low weight

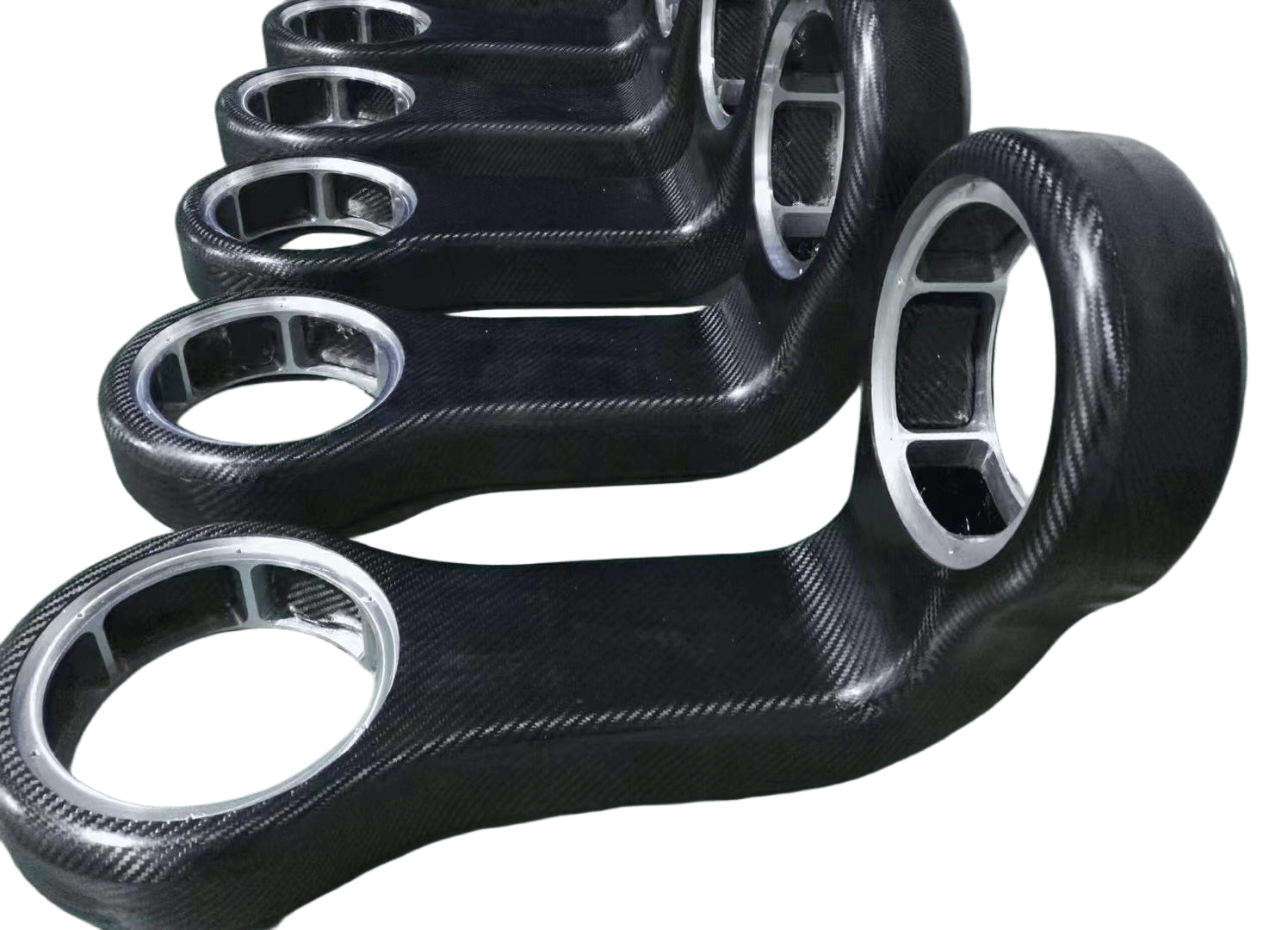

Customizable fiber orientation for directional strength

Corrosion and fatigue resistance

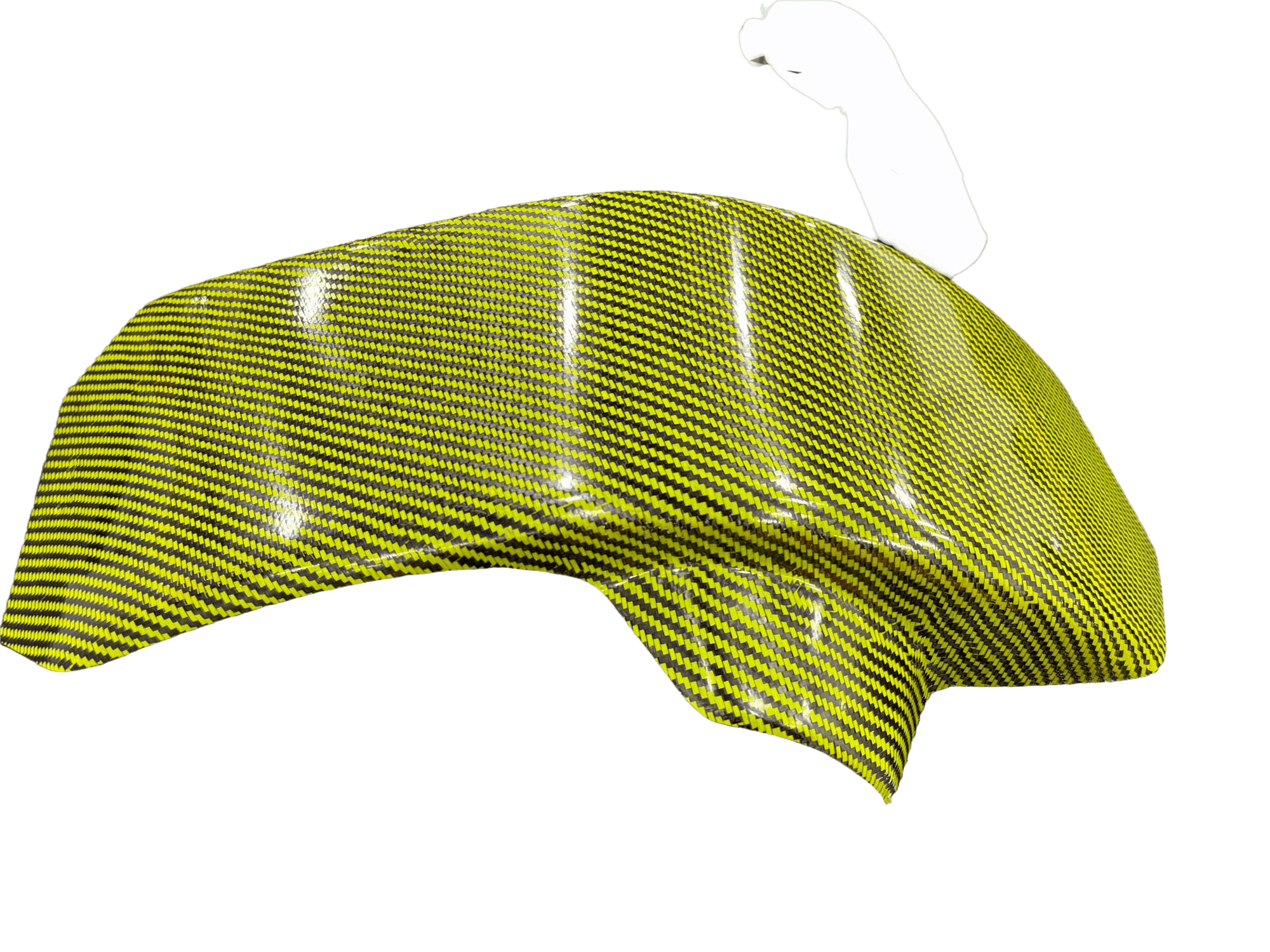

Premium surface finish with visible carbon weave

What are the Advantage of CFRP?

Ultra-lightweight — Density ~1.5 g/cm³ (40% lighter than aluminum)

Superior strength-to-weight ratio — stronger than steel at a fraction of the weight

Tunable performance — ply schedule can reinforce specific load directions

Durable & corrosion resistant — ideal for outdoor and marine environments

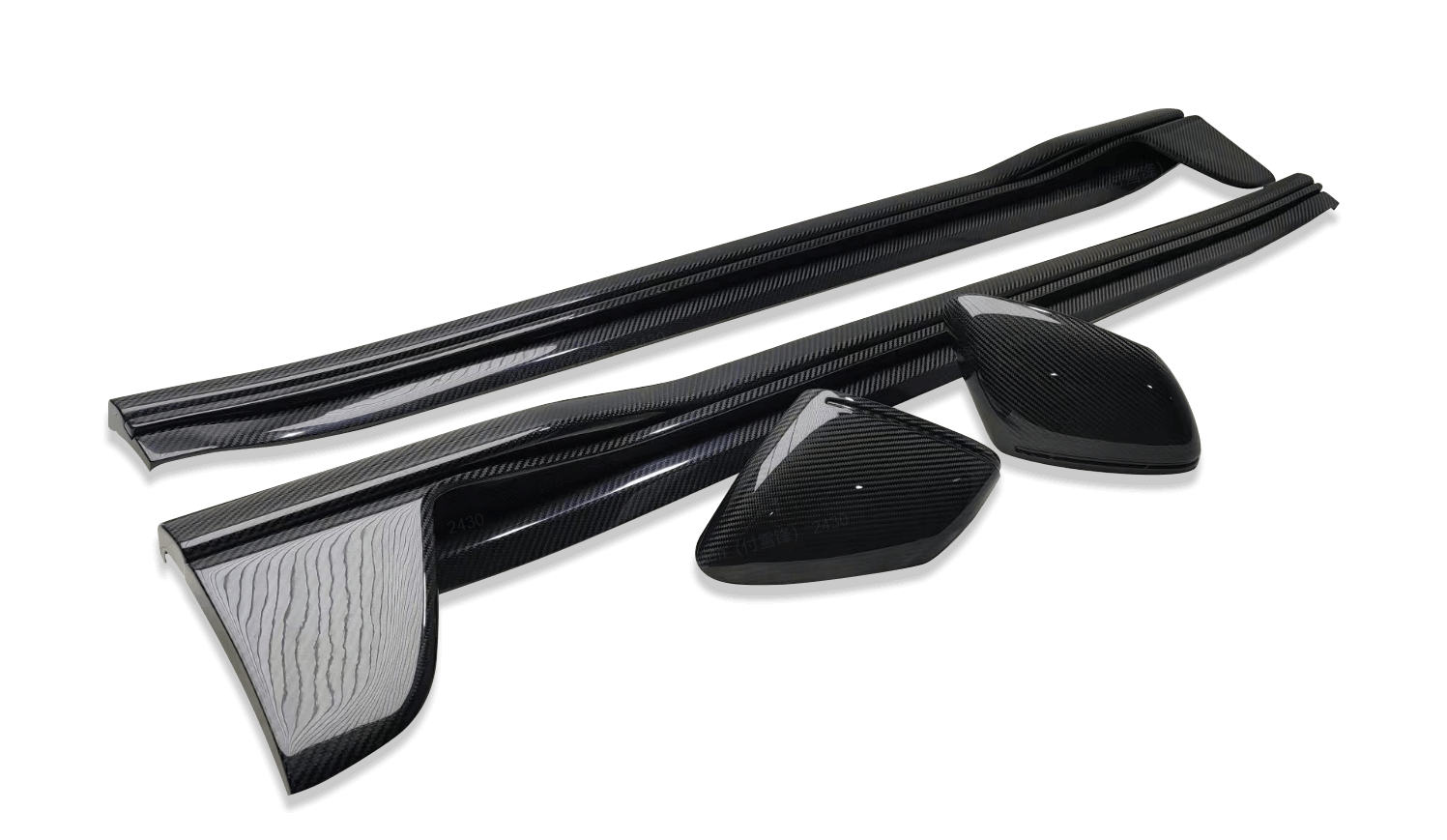

Premium look & feel — 3K twill or plain weave with glossy or matte finish

The Carbon fiber composite process

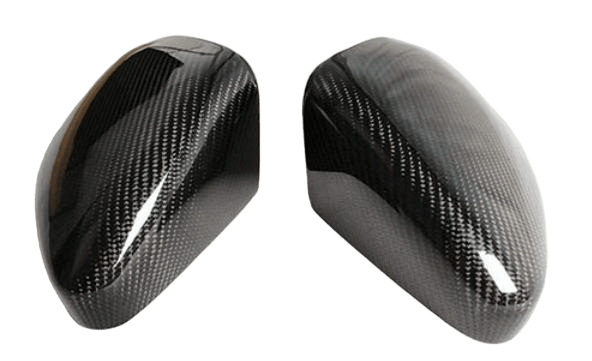

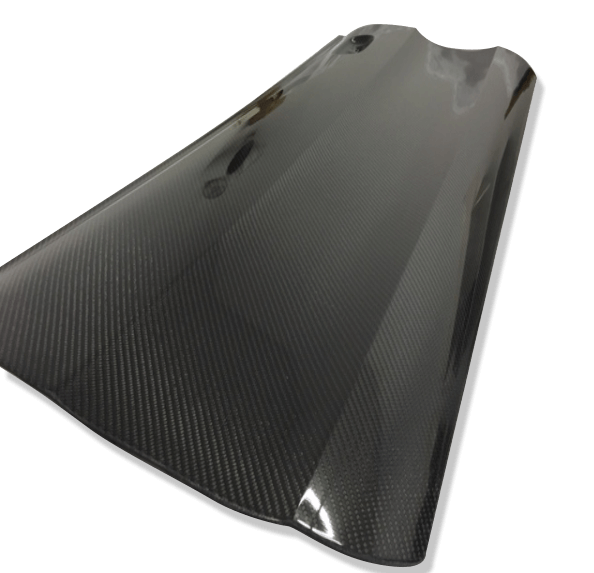

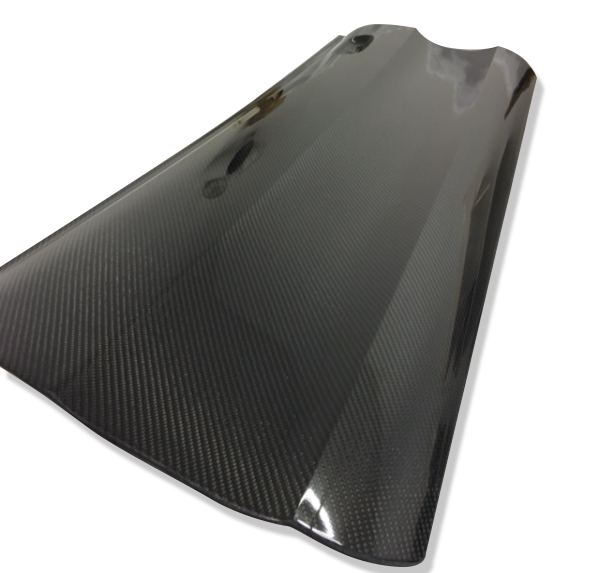

Custom Carbon Fiber Parts with light weight and high performance strength

Making the mold

Depending on the quantity and precision requirements, the mold is made using CNC machining or 3D printing.

Cut & lay the carbon fiber onto the mold

The carbon fiber fabric is cut according to the size of the part and laid onto the mold.

Vacuum & Forming

It is then placed into a vacuum bag and epoxy resin is injected, ensuring the fabric layer bonds and cures fully.

One-Stop Service: From Rapid Prototyping to Mass Production

Taking your design from early-stage testing to full-scale production has never been easier. With our wide range of capabilities, we support your journey from prototyping to mass manufacturing. Let us be the backbone of your success and your trusted one-stop partner

Early Development: 3D Pritning, CNC Machining

– Quick-turn parts to validate fit, form, and function at the earliest design stages.

Mid Development: Sheet Metal Fabrication, Vacuum casting

– Highly representative models that balance aesthetics and functionality for deeper design validation.

Production: Die Casting, Metal Casting, Injection Molding, Vacuum Forming

– Production-quality parts ready for testing, bridge runs, and full-scale manufacturing.

Why IN3DTEC For Your Prototypes and on-demand production?

From idea to production, we help you get there faster.

100,000 +

– Parts sheet metal parts produced each year.

89+

– Countries served

Broad Material Options

– 10+ metal materials.

Fast Turnaround

– Speed without compromising quality.

Expert Support

– Design optimization & engineering guidance.

Strict Quality Control

– Certified processes, reliable results.

Scalable Production

– From prototypes to mass production.

Global Service

– Worldwide delivery & logistics support.

Competitive Pricing

– Flexible and cost-effective solutions.

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

Applications: Our sheet metal parts are widely used in:

Electronics: enclosures, housings, EMI shielding

Medical: equipment housings, stainless steel fixtures

Consumer Goods: furniture components, decorative finishes

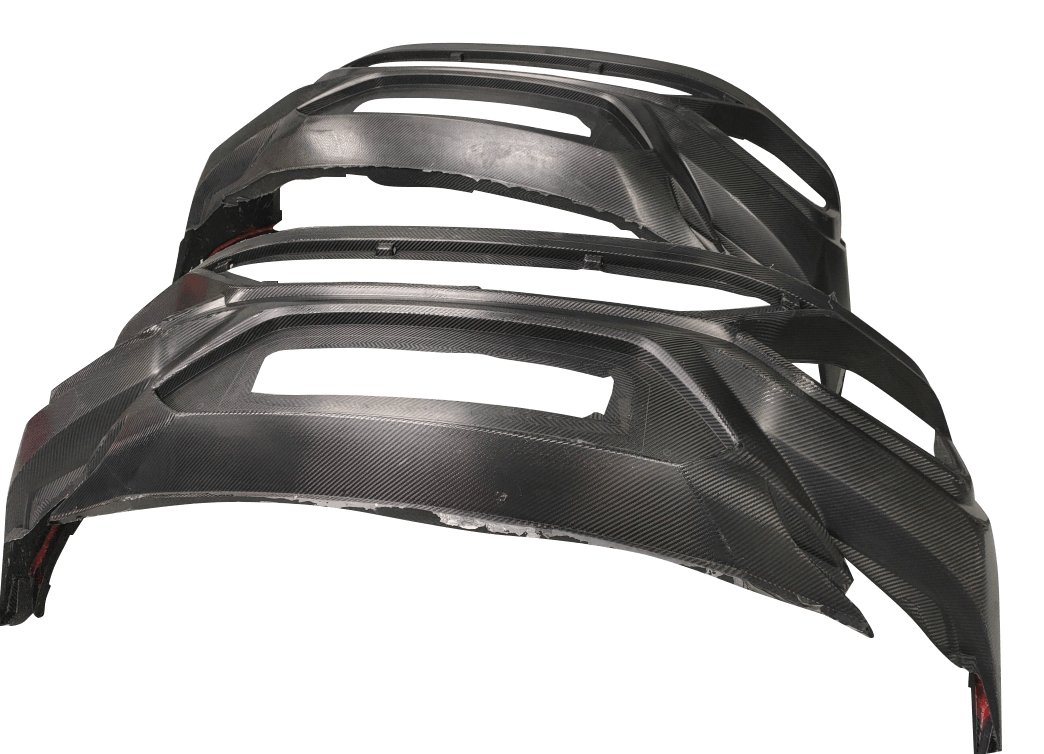

Automotive: brackets, chassis, interior panels

Aerospace: structural parts, ducts, mounts

Industrial: custom machinery covers, protective guards

Gallery Of Carbon Fiber Composite

Surface Finishes For Carbon Fiber Parts

Improve durability and performance with a selection of finishes

Glossy UV Coating

Metal Insert

Color Painting

Electroplating

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Q & A

A: Typically 15–25 copies, depending on geometry and resin type.

A: Low cost, fast turnaround, excellent surface quality, and suitability for small-batch production.

A: Automotive, consumer electronics, medical devices, robotics, and industrial design prototyping.

A: Typically ±0.3 mm / 100 mm(Min. +/-0.3mm), depending on size and geometry.

A: Yes, both tinted and fully transparent finishes are available, with painting or polishing if needed.

A: Polyurethane resins simulating ABS, PP, PC, PMMA, Rubber (shore A 30–95), and transparent materials.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文