Custom Plastic Injection Molding — From Low Volume to Mass Production

High-quality, cost-effective plastic parts with multiple molding technologies and finishing.

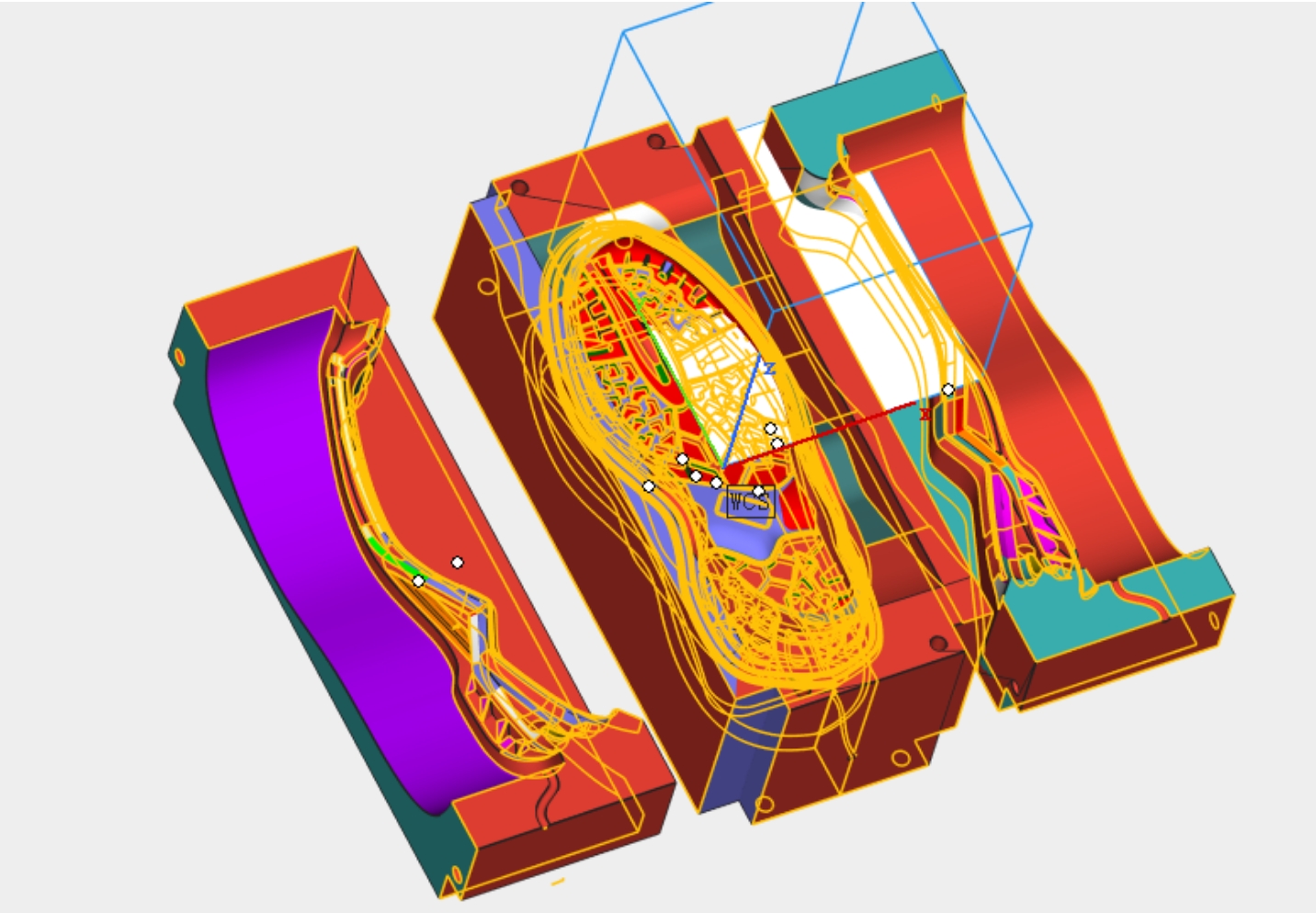

Our 3D Injection Molding Capabilities

Comprehensive injection molding capabilities covering prototypes to production, with diverse materials, advanced processes, and fast turnaround.

Low Volume Injection Molding >

Cost-effective solution for prototypes and small runs, delivering functional plastic parts quickly without high tooling investment.

Overmolding >

Adds a second material layer over a base part, enhancing grip, comfort, aesthetics, and part performance.

Insert Molding >

Combines metal or other inserts with plastic for strong, integrated components, reducing assembly steps and improving durability.

Liquid Silicone Rubber Molding >

Produces flexible, biocompatible, and heat-resistant parts, ideal for medical, automotive, and consumer applications.

Two-Shot / Multi-Shot Molding >

Molds multiple materials or colors in one cycle, achieving complex designs, enhanced functionality, and cost savings.

Compression Molding >>

Uses heat and pressure to mold thermoset plastics or composites, ensuring strength, precision, and consistent quality.

One-Stop Service: From Rapid Prototyping to Mass Production

Taking your design from early-stage testing to full-scale production has never been easier. With our wide range of capabilities, we support your journey from prototyping to mass manufacturing. Let us be the backbone of your success and your trusted one-stop partner

Early Development: 3D Printing, CNC Machining

– Quick-turn parts to validate fit, form, and function at the earliest design stages.

Mid Development: UrethaneCasting/Vacuum Casting/Metal Casting

– Highly representative models that balance aesthetics and functionality for deeper design validation.

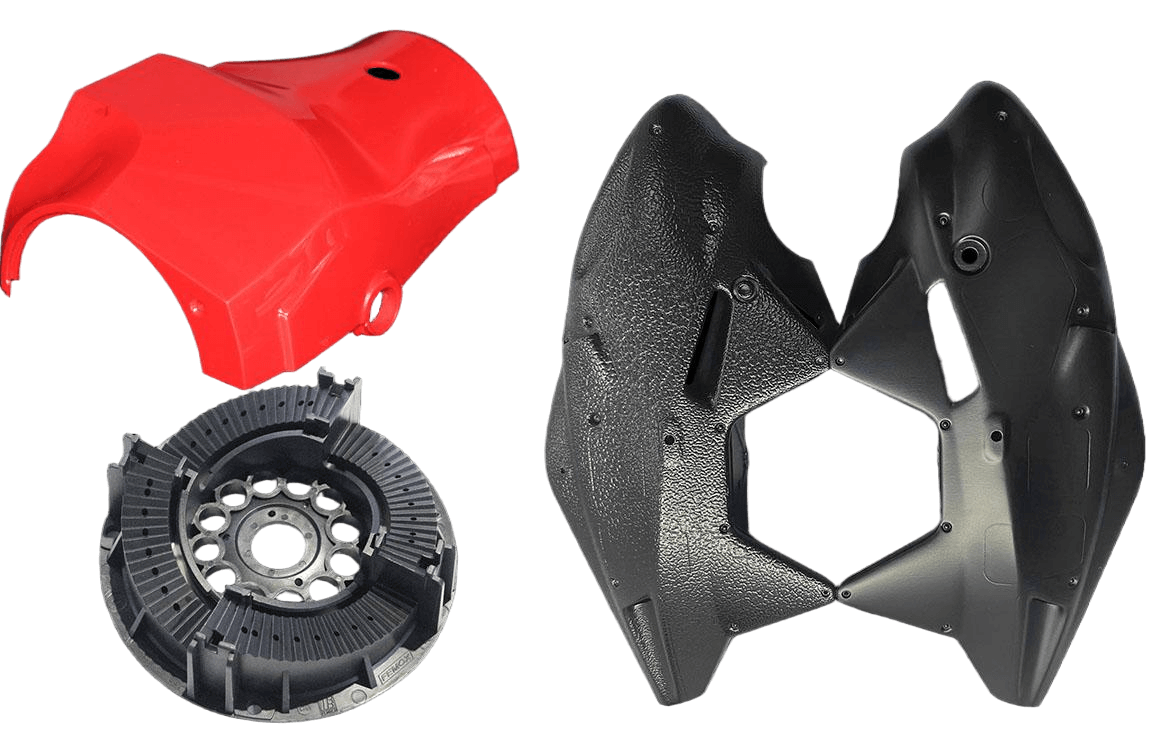

Production: Injection Molding/Die Casting,Sheet Metal

– Production-quality parts ready for testing, bridge runs, and full-scale manufacturing.

Why IN3DTEC For Your 3D Printing

From idea to production, we help you get there faster.

100,000,000 +

– Parts molded each year.

15000+

– Product developers served

Broad Material Options

– 100+Plastic,elastomeric ,composites, and custom materials.

Fast Turnaround

– Speed without compromising quality.

Strong Engineering Support

– DFM analysis, mold flow simulation, and design optimization.

Strict Quality Control

– Certified processes, reliable results.

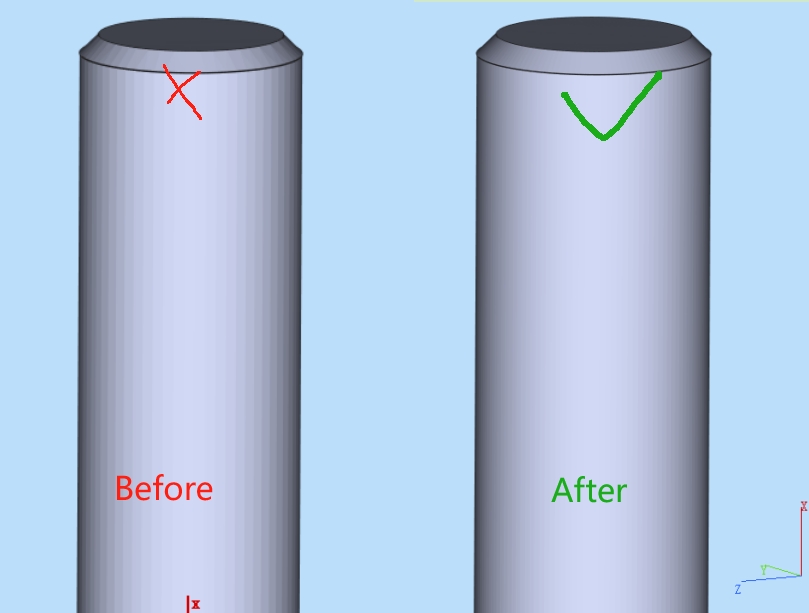

Walls are to thin, minimum recommended thickness value is 1.0

Show thin walls

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

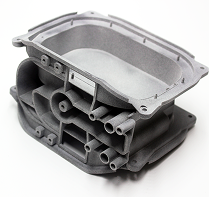

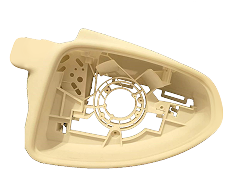

Gallery Of 3D Prints

3D Printing Materials

We offer over 100+ 3D Printing materials and a wide range of surface finishes, and we also support customized materials for special projects

| Material Name | Properties | Surface Finishes | Cost | Tensile Strength (MPa) | Bending Strength (MPa) | Young's Modulus (MPa) | Elongation at Break (%) | Charpy Impact Strength (Kj/m²) | HDT @ 0.46 MPa (°C/℉) | Applications | TDS Download |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acetal | High stiffness, low friction, good dimensional stability | VDI or SPI | Medium | 65 | 95 | 2800 | 40 | 7 | 165 / 329 | Gears, bearings, automotive parts | Download |

| Acetal Copolymer | Improved toughness over homopolymer | VDI or SPI | Medium | 60 | 90 | 2700 | 50 | 8 | 150 / 302 | Gears, electrical components | Download |

| Acetal Homopolymer / Delrin | Higher strength, slightly lower toughness | VDI or SPI | Medium | 70 | 100 | 2900 | 30 | 6 | 155 / 311 | High load gears, fuel system parts | Download |

| Nylon | High toughness, wear resistance, fatigue resistance | VDI or SPI | Medium | 70 | 120 | 3000 | 60 | 60 | 180 / 356 | Gears, bushings, automotive components | Download |

| PBT | Good electrical properties, impact resistance | VDI or SPI | Medium | 60 | 80 | 2400 | 20 | 8 | 140 / 284 | Electrical housings, connectors | Download |

| PC / ABS | Blend: impact resistance + toughness | VDI or SPI | Medium | 55 | 75 | 2300 | 80 | 60 | 120 / 248 | Automotive interiors, electronics housings | Download |

| PC / PBT | Blend: chemical resistance + strength | VDI or SPI | Medium | 60 | 80 | 2400 | 50 | 50 | 130 / 266 | Automotive bumpers, electrical housings | Download |

| PET | Good toughness, chemical resistance, transparency | VDI or SPI | Medium | 55 | 80 | 2800 | 150 | 5 | 120 / 248 | Bottles, films, fibers | Download |

| PETG | Good clarity, toughness, chemical resistance | VDI or SPI | Medium | 50 | 65 | 2200 | 200 | 7 | 80 / 176 | Packaging, bottles, consumer goods | Download |

| PMMA (Acrylic, Plexiglas) | High clarity, rigidity, weather resistance | VDI or SPI | Medium | 70 | 110 | 3300 | 5 | 12 | 80 / 176 | Lenses, displays, lighting covers | Download |

| Polycarbonate | High strength, impact resistance, optical clarity | VDI or SPI | Medium-High | 60 | 90 | 2400 | 110 | 75 | 135 / 275 | Safety glasses, automotive parts, electronic housings | Download |

| PPE / PS | Good dimensional stability, electrical insulation | VDI or SPI | Medium | 60 | 75 | 2600 | 20 | 15 | 140 / 284 | Electrical housings, automotive parts | Download |

| TPU | Elastic, flexible, abrasion resistance | VDI or SPI | Medium | 35 | 40 | 20 | 500 | 80 | 60 / 140 | Seals, gaskets, footwear, flexible parts | Download |

| Material Name | Properties | Surface Finishes | Cost | Tensile Strength (MPa) | Bending Strength (MPa) | Young's Modulus (MPa) | Elongation at Break (%) | Charpy Impact Strength (Kj/m²) | HDT @ 0.46 MPa (°C/℉) | Applications | TDS Download |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LCP | High strength, heat resistance, chemical resistance | VDI or SPI | High | 200 | 230 | 6000 | 5 | 15 | 280 / 536 | Connectors, electronic components, automotive parts | Download |

| PEEK | High strength, heat resistance, chemical resistance | VDI or SPI | High | 90 | 160 | 3600 | 50 | 55 | 250 / 482 | Aerospace, medical implants, high-performance parts | Download |

| PEI | High heat resistance, good mechanical properties | VDI or SPI | High | 100 | 170 | 3400 | 60 | 45 | 215 / 419 | Medical devices, electrical components, aerospace | Download |

| PPA | High heat resistance, mechanical strength | VDI or SPI | High | 120 | 150 | 4000 | 5 | 10 | 280 / 536 | Automotive under-hood, electronics | Download |

| PSU | High heat resistance, strength, transparency | VDI or SPI | High | 75 | 95 | 2600 | 30 | 20 | 190 / 374 | Medical devices, automotive lighting, membranes | Download |

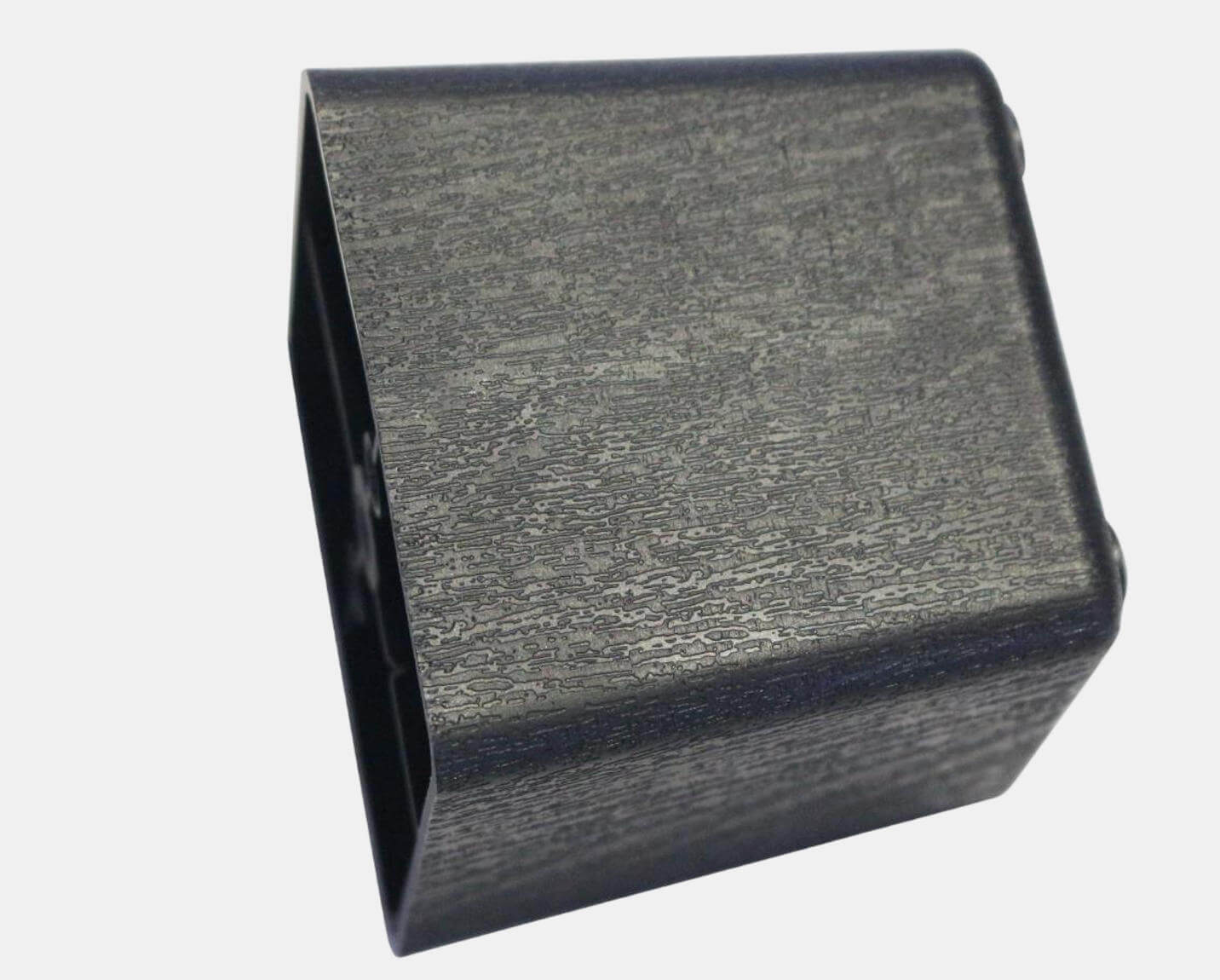

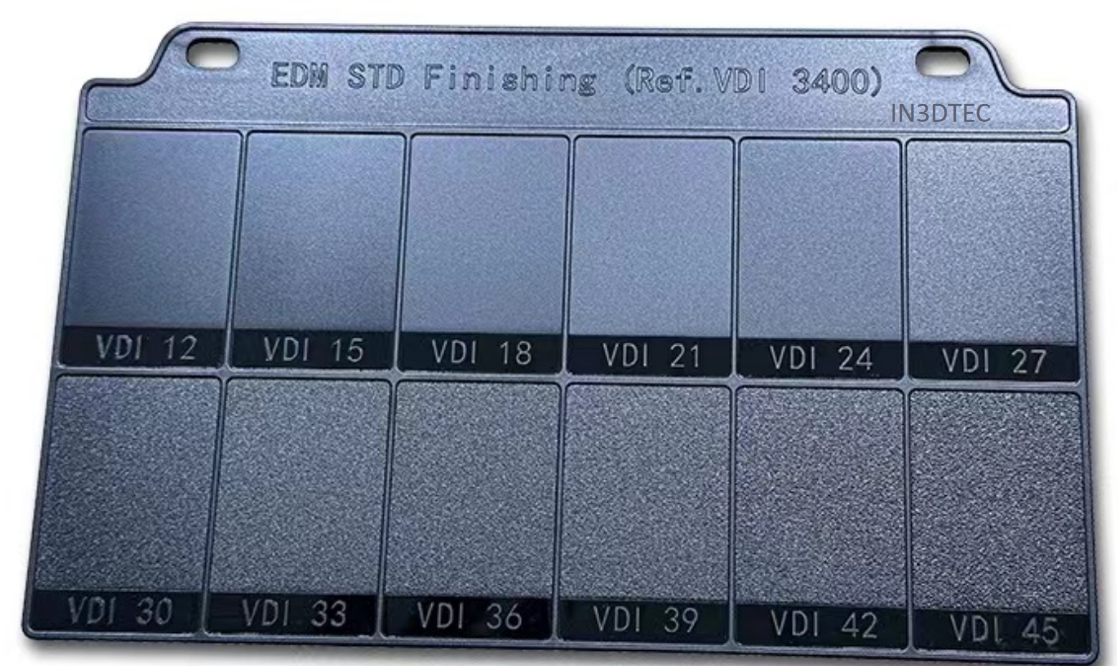

Surface Finishes For Injection Molding- VDI & SPI standard Improve durability and performance with a selection of finishes

Assembly

Ahesive bonding

Plating

Part marking/Laser engraving

Color Matching

Insert

Thread Tapping

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Put your Parts into Production Now

Manufacturing Resources

View All

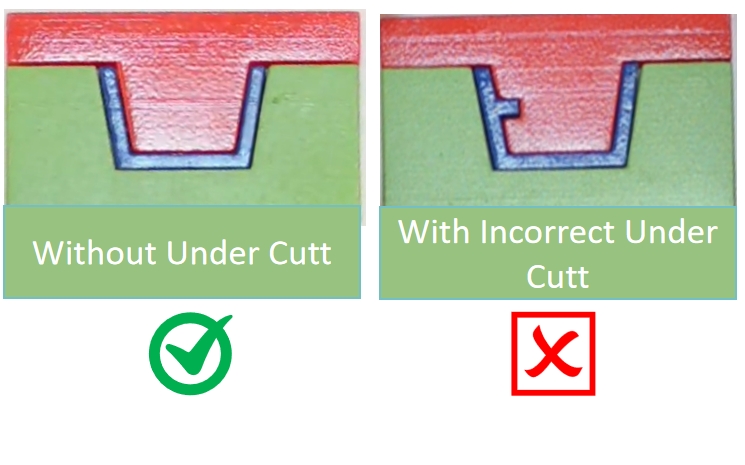

Designing Undercuts for Injection Molding: A Comprehensive Guide

When it comes to injection molding, designing undercuts can be a critical aspect that impacts both the manufacturability and functionality of your part. Undercuts are features that complicate the ejection process, making it essential to understand how to

Read More

injection molding surfece finishes: VDI vs SPI

Introduction: Injection molding is a widely used manufacturing process that allows for the production of complex and precise plastic parts. Two variations of injection molding, two-shot molding and overmolding, offer unique capabilities and advantages. I

Read More

Top Free Tools for Repairing STL Files in 3D Printing

3D printing has revolutionized the way we create objects, but it’s not without its challenges. One common issue that many enthusiasts face is dealing with corrupted or flawed STL files. Fortunately, there are several free tools available that can help you

Read More

How to Export Your CAD Files for a Smoother Surface Finish

In the world of 3D printing and manufacturing, the quality of your final product is heavily influenced by how you export your CAD files. A smooth surface finish can enhance aesthetics, improve functionality, and reduce post-processing work. In this blog,

Read MoreQ & A

A: High precision, excellent surface finish, low per-part cost for high volumes, and repeatability.

A: Depending on material and mold type, anywhere from thousands to over a million cycles.

A: Yes, with aluminum or soft steel molds, it’s suitable for prototyping and low runs.

A: Typically ±0.1 mm, but precision can be higher depending on design and material.

A: Glossy, matte, textured, polished, or custom finishes depending on mold treatment.

A: Uniform wall thickness, draft angles, ribbing for strength, and avoiding undercuts when possible.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文