0 +

Years Experience

0 +

Materials & Finishes

0 +

Countries Served

0 +

Customers Trusted us

0 %

On Time Delivery

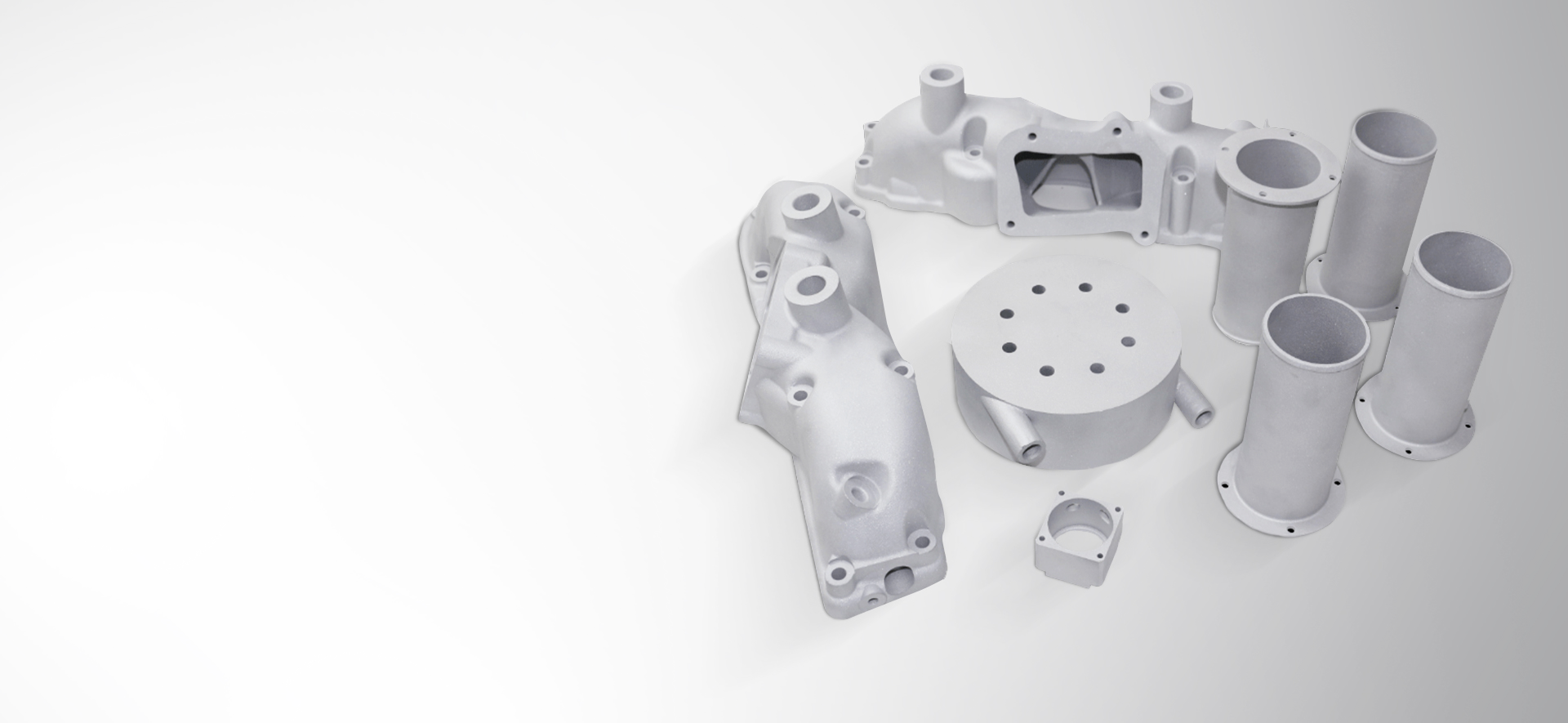

IN3DTEC Manufacturing Capabilities To Meet Your Needs

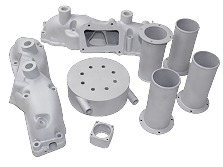

3D Printing>

FDM, SLM, SLA, SLS, DLP, MJF, Ceramic, Sand printing & Casting, Colorful parts. As fast as one day.

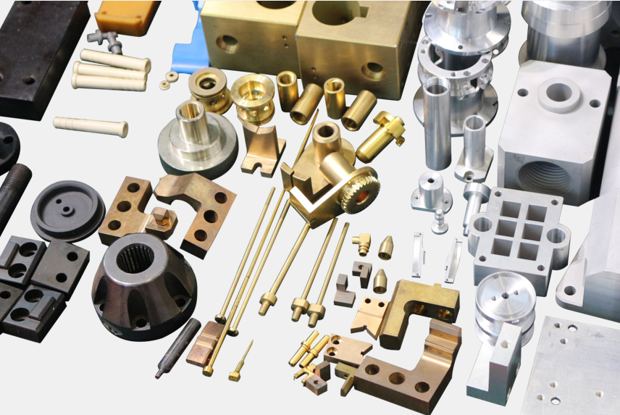

CNC Machining>

CNC Milling ( 3,4, 5 axis) CNC Turning, EDM. up to ±0.003mm (±0.0001in)

Injection Molding>

Insert Molding, Over molding, Low volume Injection Molding. No MOQ, from 1 to 1M parts.

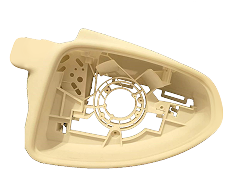

Vacuum Casting/Urethane Casting >

ABS, PP, Nylon, PC, TPU/Rubber, Transparent. Best alternative of injection molding for low volume run.

3D Scanning>

Low cost to create CAD file with 1-3 days. Creating format in STL or STEP.

Carbon Fiber Composites>

High-strength, lightweight for durable, precise, and performance-driven engineering applications.

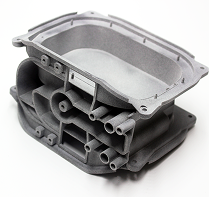

Die Casting>

Aluminum/Zinc/Magnesium/Copper. 0.03in walls, 1000+ unit batches.

Sheet Metal>

Expert laser cutting, bending, welding & stamping. Fast, high precise.

From Quote To Delivery

Everything You Need in One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving your time and ensuring smoother part production.

No Minimum Quantity

AI-Powered DFM Analysis

Online Order Management

Flexible Lead Time & Shipping Options

Walls are too thin, minimum recommended thickness value is 1.0

Show thin walls

What is the most cost-effective way to make a transparent part?

SLA is a good choice for a prototype. other options can be vacuum casting and CNC machining.

Can you print titanium, which grage?

We can print Titanium, Grade 5.

Can you ship parts to the united kingdom?

Yes, we can ship parts globally.

what's the tolerance of metal printing?

0.2% X length, +/-0.2mm minimum.

AI-powered & Human Technical

Assistant

Our AI-powered bot instantly assists with material selection, order processing, shipping updates, and other common inquiries. For more personalized support, you can switch to our human customer service team at any time via WhatsApp, Google Meet, Zoom, or Microsoft Teams.

Why IN3DTEC Standout?

Various of capability

With 400+ machines and over 160 materials and surface finishes, we offer customers a complete one-stop solution for part production

Fats and Affordable

Each order is managed by a dedicated sales representative, while we control costs at every stage to provide our customers with competitive pricing.

Engineering Support

More than just making parts, we deliver value — our designers and machinists support customers throughout the entire workflow.

Quality Assurance

At IN3DTEC, quality is our priority — from raw materials to final inspection, all processes are.

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

Manufacturing Resources

View All

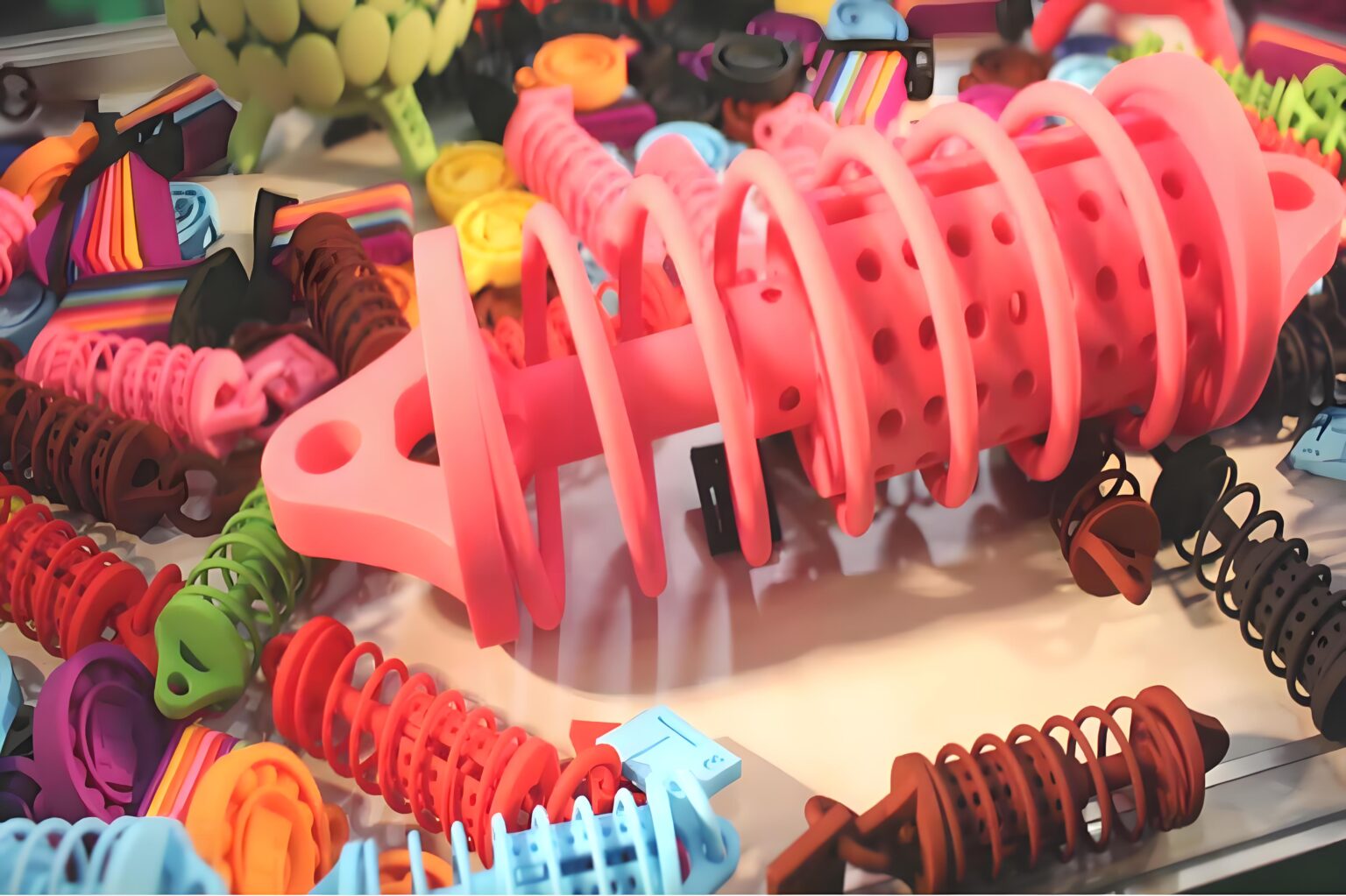

Cool & Useful Things, ideas to 3D Print for November

100 cool & useful 3D Print Projects, Ideas You’ll Love In the ever-evolving world of technology, 3D printing stands out as a game-changing tool that

Read More

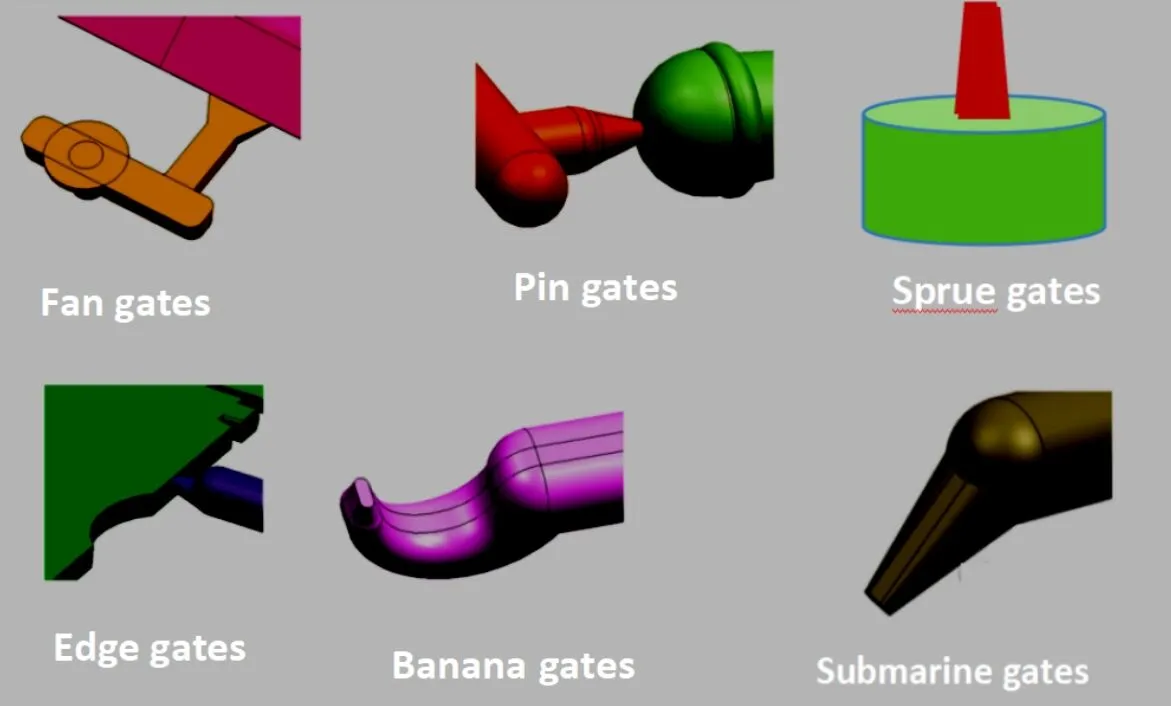

A Comprehensive Guide to Injection Molding Gates

Comprehensive Guide to Injection Molding Gates Introduction: Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. A

Read More

Selective Laser Sintering (SLS) Material Selection Guide for Low Volume Production

Selective Laser Sintering (SLS) Material Selection Guide for Low Volume Production In recent years, Selective Laser Sintering (SLS) has emerged as one of the most

Read More

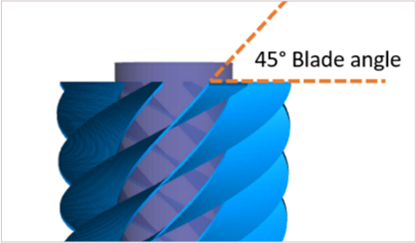

How to design parts for metal 3D Printing

With the gradual popularization of 3D printing, more and more users will directly consider metal printing when producing products, so how to design a product suitable for metal printing? Is anything we should pay attention to? IN3DTEC will analyze the des

Read More

Modernizing Metal Casting with Sand 3D Printing

Modernizing Metal Casting with Sand 3D Printing For centuries, metal casting has been a trusted method to produce strong, complex parts across industries—from automotive and

Read MoreHow to Work With

Upload a CAD File

Simply upload your CAD file

Get Quote with DFM

Get real-time pricing and DFM insights within seconds. Or Ask for manual dsign help.

Manufacturing Begins

Once your order is placed, We’ll begin production Right away, and you can track and manage it anytime from your dashboard

Parts are Shipped

Partnering with FedEx, DHL and UPS, we deliver your parts fast and on time, Worldwide

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文