- Author

- 24 January 2026

Acrylic CNC Machining Services: Clarity, Precision, and How to Get It Right

When it comes to creating clear, accurate, and durable plastic parts, acrylic (PMMA) is a top choice for engineers, product designers, and fabricators. At IN3DTEC, we specialize in CNC machining acrylic components that require both optical quality and tight tolerances. Whether you need prototypes, small batch production, or custom display parts, our team delivers consistent quality—fast, affordable, and globally.

Why Acrylic?

Acrylic, also known as PMMA (Polymethyl Methacrylate), is a transparent thermoplastic with excellent mechanical and optical properties. It’s commonly used as a lightweight and shatter-resistant alternative to glass, and it machines well with CNC processes when the right parameters are applied.

Key Benefits:

These properties make acrylic suitable for both functional and decorative applications.

Applications of CNC Machined Acrylic

Our customers use CNC machined acrylic in a wide variety of industries:

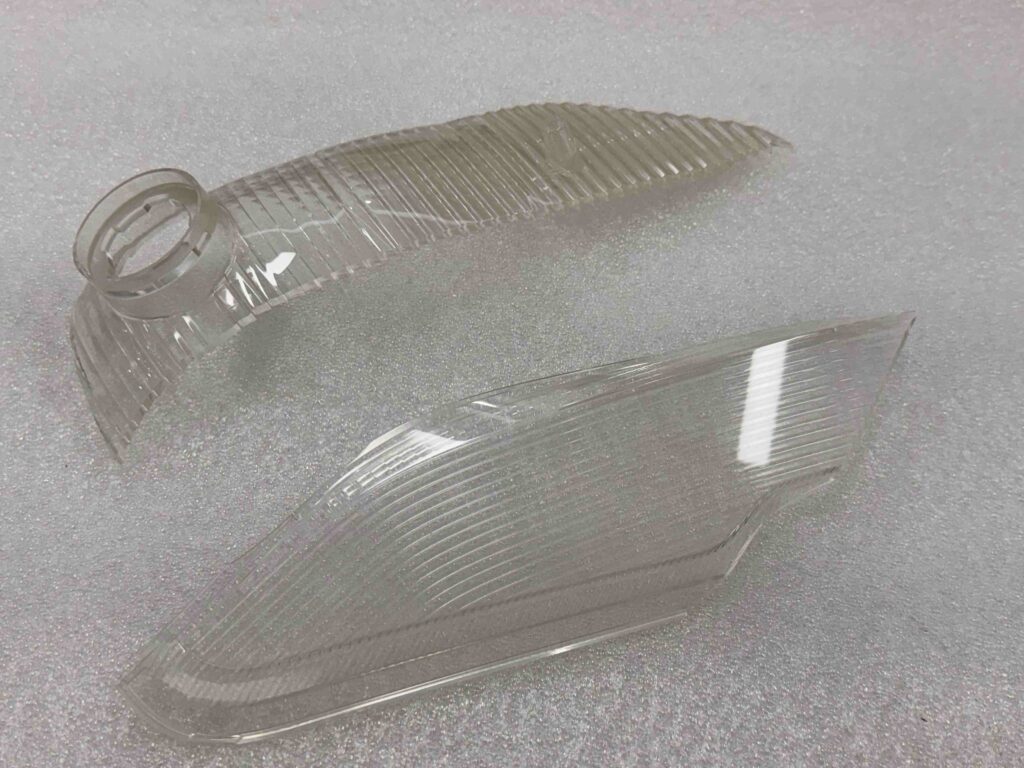

Lighting – Custom lenses, diffusers, light guides

Medical & Laboratory – Transparent panels, biofluid devices

Consumer Electronics – Enclosures, interface displays

Automotive – Interior trim mockups, light covers

Retail & Display – Cosmetic stands, product showcases

Prototyping – Visual models and test-fit assemblies

Our Capabilities

At IN3DTEC, we use high-precision 3-axis and 5-axis CNC machines to produce acrylic parts with smooth edges, clean holes, and crystal-clear surfaces. Our services include:

CNC milling and turning of acrylic blocks and sheets

Clear, colored, or frosted acrylic options

Tight tolerance machining (±0.05 mm)

Polishing for optical or aesthetic finishes

Small or mid-volume production — No MOQ

Surface Finishing Options of Acrylic CNC Service

To enhance the look and function of your acrylic parts, we offer various finishing services:

Polished – Glass-like clarity for transparent components

Matte/Frosted – For anti-glare or diffused appearance

Flame polishing – Especially for curved edges

Edge smoothing & deburring – For safe, clean part handling

Painting- Creates colorful acrylic parts

How to CNC Acrylic: Best Practices & Settings

CNC machining acrylic requires the right tooling and process settings to avoid issues like melting, chipping, or poor surface finish. Here’s what we recommend:

Tooling

Use single-flute or O-flute carbide end mills (1.5mm–6mm)

Sharp tools reduce stress and prevent surface clouding

Machining Parameters

Spindle speed: 12,000 – 18,000 RPM

Feed rate: 500 – 1,500 mm/min

Depth per pass: Roughing: 0.5 – 1.0 mm;Finishing: 0.1 – 0.3 mm

Cooling

Use air blast or mist coolant

Avoid flood cooling to prevent microcracks or hazing

Post-Processing

We offer polishing (mechanical, flame, or vapor) for maximum transparency

Bonding and gluing services for multi-part acrylic assemblies

Other technology for making transparent prototypes.

There are many other technologies can make transparent parts, among them, SLA 3D Printing service is one of the best choices. At IN3DTEC, we have different types of industrial SLA 3D Printers which ideal for making acrylic-like part.

Why Choose IN3DTEC?

With years of experience in CNC machining and plastic fabrication, IN3DTEC provides reliable, cost-effective solutions for customers across the globe. Our strength lies in fast lead times, tight tolerances, and customer-first communication—plus, we ship internationally.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文