Modernizing Metal Casting with Sand 3D Printing

For centuries, metal casting has been a trusted method to produce strong, complex parts across industries—from automotive and aerospace to machinery and art. But thanks to additive manufacturing, the traditional casting process is evolving. One of the most promising innovations is sand 3D printing, which is now available at IN3DTEC service, sand printing combines the precision and speed of 3D printing with the robustness of metal casting.

What Is Sand 3D Printing?

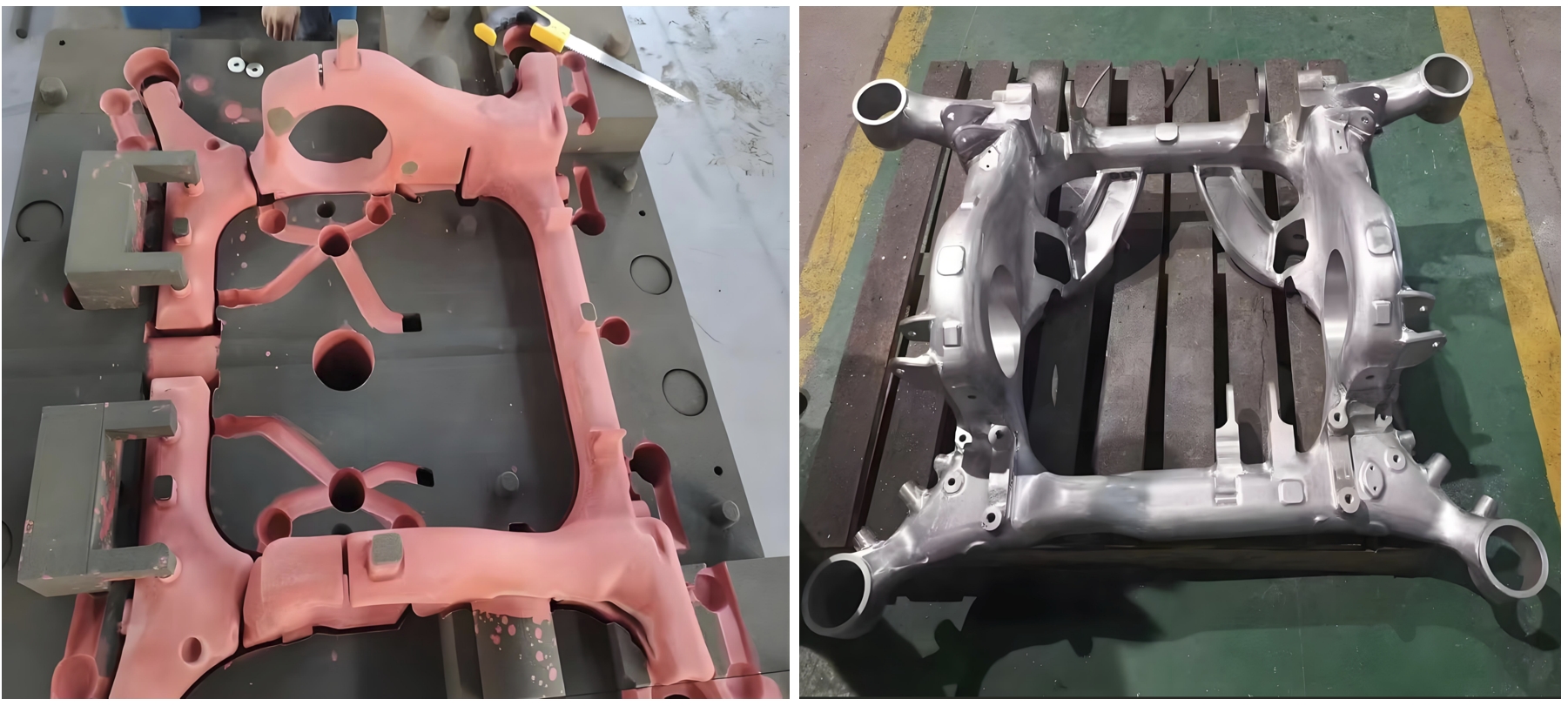

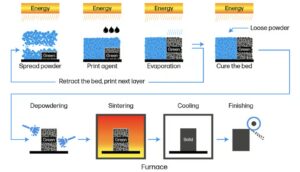

There are many different types of metal casting process, while metal casting combined with Sand 3D printing is still new to public, so what is sand 3D Printing? Sand 3D Printing creates sand molds and cores by layering fine sand with a binder material. Unlike conventional mold-making, this method doesn’t require a physical pattern or tooling. Instead, it uses a digital 3D model (usually a CAD file) to print the mold directly.

The result? Highly detailed sand molds that are ready for pouring molten metal—all without expensive or time-consuming tooling.

Benefits of Sand 3D Printing in Metal Casting

1. Tool-Free, Cost-Effective Production

Traditional casting often involves creating wooden or metal patterns, which can be costly and slow. With sand 3D printing, you eliminate the need for physical molds, making it ideal for prototyping, low-volume production, and one-off parts.

2. Complex Geometries, No Limits

Designers can create parts with internal channels, undercuts, and other complex features that would be nearly impossible—or extremely expensive—using traditional mold-making methods. This opens the door to highly optimized and lightweight metal parts.

3. Faster Turnaround

Because molds are printed directly from CAD models, lead times are significantly reduced. A part that might take weeks to prepare using traditional tooling can be ready in a matter of days with sand 3D printing.

4. Wide Material Compatibility

Once the sand mold is printed, it can be used for casting almost any metal, including aluminum, stainless steel, carbon steel, bronze, and nickel alloys.

Real-World Applications

Automotive: Engine blocks, intake manifolds, turbo housings, and more.

Aerospace: Lightweight structural components and cooling channels in turbine blades.

Industrial Equipment: Pump housings, valves, and heavy-duty connectors.

Art & Restoration: Custom sculptures and heritage part reproductions.

Why Combine Sand 3D Printing with Casting?

Rather than replacing metal casting, sand 3D printing enhances it. It bridges the gap between digital design and traditional manufacturing, helping manufacturers:

Shorten R&D cycles,

Minimize waste and tooling investment,

Increase design freedom, and

Produce low-volume parts with high efficiency.

For industries that rely on complex, high-strength parts but want to avoid high upfront tooling costs, this hybrid approach offers the best of both worlds.

Are Cast Metal Parts from Sand 3D Printing Ready to Use?

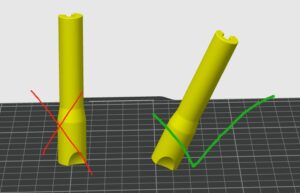

This is a common question among engineers and buyers: Can metal parts made using sand 3D printed molds be used directly without additional machining? The answer depends on the part’s function and the required tolerances.

While sand 3D printing enables high geometric accuracy for molds, the casting process itself still follows traditional limits. That means dimensional tolerances are typically within ±0.5–2.0 mm, depending on the part size and metal type. For functional parts requiring tight tolerances—such as sealing surfaces, threads, or bearing seats—CNC machining or other finishing steps are often necessary.

Post-Processing Considerations

After casting, parts may require several common finishing steps:

Surface cleaning (e.g., sandblasting or shot peening) to remove residual sand or oxides.

Heat treatment, especially for steel or aluminum alloys, to improve mechanical properties.

Machining of critical surfaces to meet dimensional and surface finish requirements.

Inspection using CMMs or 3D scanning for quality assurance.

In some cases, especially for art pieces or non-load-bearing components, no further processing is needed, and the raw cast finish is acceptable or even desirable.

Final Thoughts

As global manufacturing becomes more agile and customized, combining sand 3D printing with metal casting presents a smart solution for companies looking to stay competitive. Whether you’re producing prototypes or functional parts, this method allows for flexibility, speed, and precision.

Looking to bring your metal part designs to life quickly and affordably? Get in touch with our team at IN3DTEC to explore how sand 3D printing and casting can work for your next project.