vacuum casting Service

Functional and end-use parts | Low cost for molds | As fast as 3 days

All uploads are secure and confidential

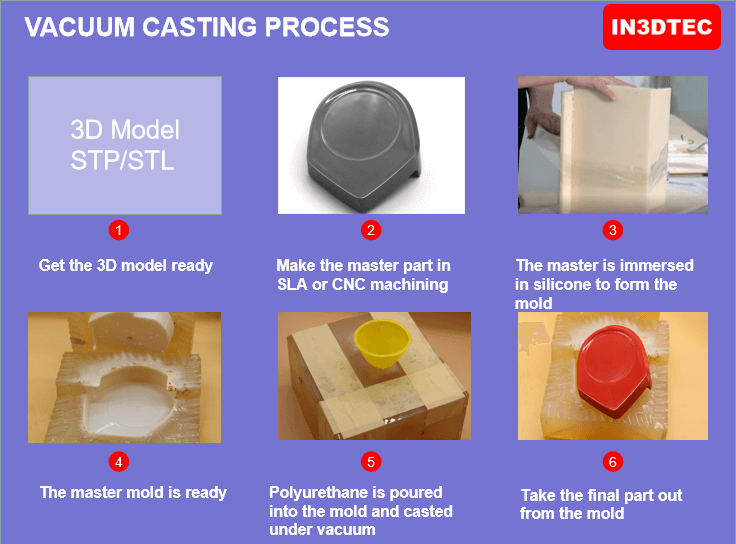

What is vacuum casting?

Vacuum casting or Urethane casting is a method for making high-quality prototypes or low volumes of parts formed from inexpensive silicone molds, and it is a copy technique for producing functional and end-use parts.

Advantages of vacuum casting

- Low cost for molds

- One silicone mold can accurately cast about 20 parts

- Materials from flexible to extremely rigid and impact resistant

- Quick turnaround with high quality

The materials available by vacuum Casting service from iN3DTEC

We offer an exceptional range of 15 carefully selected polyurethanes that are similar to Acrylic, Rubber, PP, ABS, and PC. These materials cast to an outstanding variety of properties and offer the possibility to match colors and finishes.

Contact us for more detailed information to select the most suitable material for your products

ABS-like

> Similar to ABS

> Heat resistance to 77 Celsisus

> High tesnsile modulus (2250Mpa)

Water Clear PC-like

> Transparent or any customized color

> Heat resistance to 80 Celsisus or more

> High mechanical properties

PA-like

> Similar to nylon

> Can be reinforced by CF or GF

> High impact strength and stiffness

Water clear acrylic

>Clear or trasnparent

> Similar to PMMA

> High accuracy with stable dimension

PP-like

> Similar to PP

> Heat resistance to 90 Celsius

> Impact resistance and toughness

Rubber-like

> Similar to Rubber

> From Shore 30A to Shore 95A

> Smooth Surface with customized color

Advantages of vacuum casting

- 6-10 days Production

- Low production cost

- Excellent material performance

- Customized surface finishes and colors

- Part Consistency

- Thin-wall casting

Vacuum casting is ideal for

- Pre-launch product testing

- Concepts models and prototypes

- Low volume production

- Housing & cover

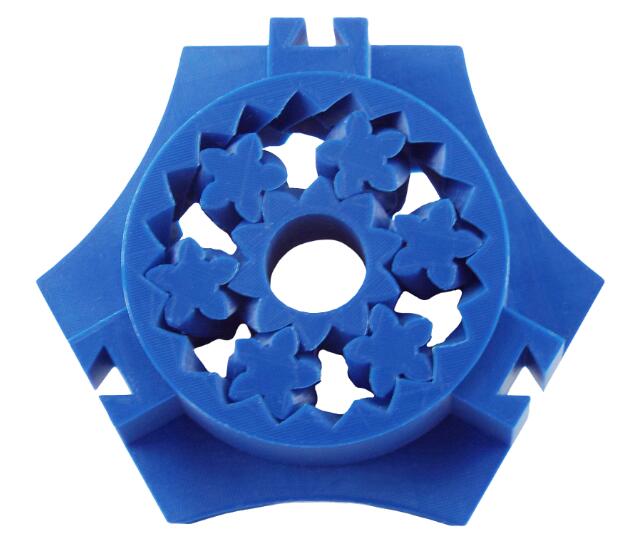

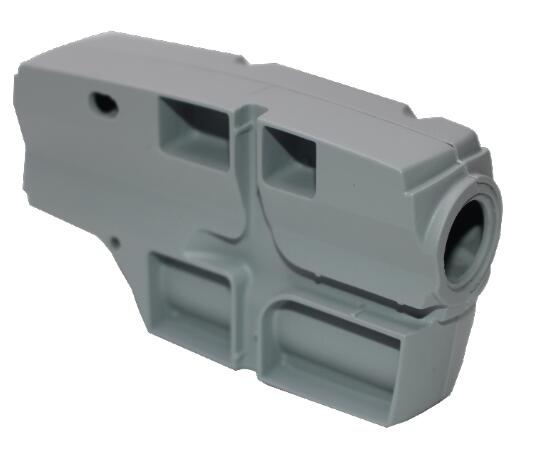

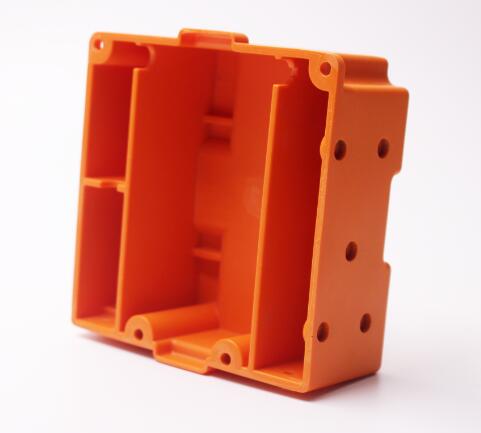

See our projects-vacuum casting service ↓

Vacuum Casting Design Equipment in IN3DTEC

Technical specifications

Max. casted dimensions: 1600 x 1000 x 1000mm

Lead time: 3 to 7 working days

Standard accuracy:+/-0.3%( length under 100mm with +/-0.3mm limit)

Color: Any customized Pantone No. color

Surface finishes: As good as injection molding, Matte, glossy, UV coating, Alcohol resistance coating, or any other finishes.

Get The Free Design Guides Of Vacuum Casting

0.5mm

0.8mm

0.5mm