FAQS

What’s the advantage of working with IN3DTEC?

Our digital manufacturing factory offers industrial 3D scanning, reverse engineering, 3D printing, CNC machining, Vacuum or Urethane Casting, Injection Molding, Sheet metal fabrication services, it is like a one-stop station for your prototypings or end-use productions. We help you find processing risks, reduce cost, delivery parts quickly with high quality.

How to protect my intellectual property? Do you guys provide NDA if necessary?

All uploaded files are secure and confidential. If you would like some additional reassurance, we can send you our Non-Disclosure-Agreement.

What industry do you serve?

Aerospace, Automotive, Consumer products, Electronics, Education-Universities, Lighting, Medical, Technology…

How many machines do you have?

So far, we have more than 300+ mills, 3D printers, Vacuum chamber, lathes and other manufacturing equipment.

How much does laser scanning cost?

3D scanning a part can cost anywhere from 100$ to 1000$ or more, our rates are between 50$ to 150$ per hour, depending on the size and complexity the parts being scanned.

How accurate are 3D scanners?

We have different 3D scanners with accuracy from 0.05 to 0.1mm.

How do you scan a project for 3D printing?

- Prepare the object for scanning, spray coat or sticker the surface to improve the accuracy

- Make a appropriate distance between scanner and scanned objects

- Refine the mesh

- Import the data into CAD

- Repair the broken surface

- Integrate new objects

- Ready for 3D printing

Do I need to send my parts to you guys for scanning?

Yes, and we will send it back with the final 3D Printed parts back to you

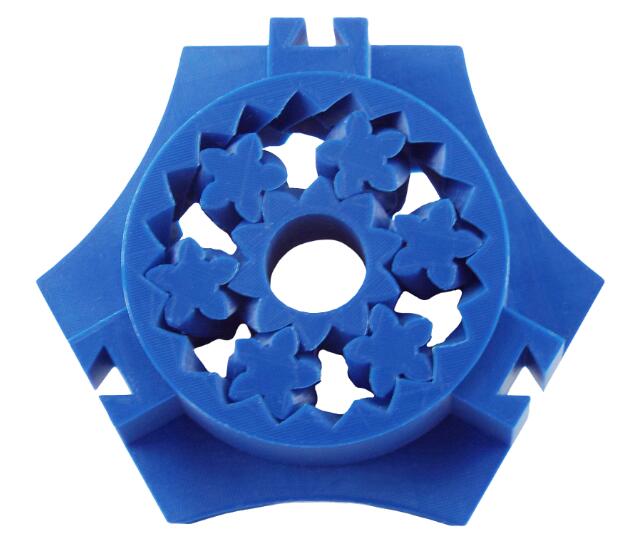

What 3D Printing technologies can you offer?

FDM, SLA, DLP, SLS, MJF, SLM, DMLS, PolyJet. From plastics to metals.

What 3D printing can be used for?

3D Printing is used for making prototypes and ideal for low-volume production.

How does it cost to get 3D Printed parts?

It depends on how much the material will be used in your prints, normally speaking, the cost is caculated on its weight instead of the geometry structure. The best way is to upload your file to get an instant quote.

What is Fused Deposition Modeling FDM?

Fused deposition modeling (FDM) is one of the most widely used additive manufacturing processes for fabricating prototypes and functional parts in common engineering plastics. The simplicity, reliability, and affordability of the FDM process have made the additive manufacturing technology widely recognized and adopted by industry, academia, and consumers.

What is Stereolithography SLA?

Stereolithography is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. Stereolithography 3D printing is a highly recommended technology for making custom parts in prototype and production settings, often acting as a stand-in for injection molded plastic parts.

What is Selective Laser Sintering SLS?

Selective laser sintering (SLS) uses a CO2 laser that draws onto a hot bed of thermoplastic powder. Where it draws, it lightly sinters the powder into a solid. After each layer, a roller lays a fresh layer of powder on top of the bed and the process repeats. Since SLS uses actual engineering thermoplastics, its 3D-printed parts exhibit greater toughness.

What is Multi Jet Fusion MJF?

Multi Jet Fusion is an industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day. Final parts exhibit quality surface finishes, fine feature resolution, and more consistent mechanical properties when compared to processes like selective laser sintering.

What is Direct Metal Laser Sintering?

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. It builds the metal parts from a CAD file using a laser selectively fuse a fine metal powder. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques. DMLS provides a fast way to produce metals such as aluminium, stainless steel, titanium strong end-use parts.

How can I find the most suitable material for my application?

We have application engineers with a master’s degree in chemistry, with more than 8 working experience in different industries.

What is Vacuum casting?

Vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. It is a copy technique for producing funcational and high quality end-use parts.

What is the difference between vacuum casting and urethane casting?

They are the same technology, but with different names. Polyurethane(urethane) is a material used to make parts. The process is carried out under vacuum casting equipment.

What is a vacuum casting machine?

A vacuum casting machine uses a vacuum to suck the molten metal into the mold. … The idea is to have a steady, constant pressure pushing or pulling the molten metal into the mold. The centrifugal machine must be securely bolted to a level surface with a protective fence around it.

Is vacuum casting and investment casting the same technology?

They are two completely different technologies, investment casting, also known as precision casting or lost-wax casting, is a manufacturing process in which a wax pattern is used to shape a disposable ceramic mold.

We have 3D Printer can print wax parts directly.

What do you offer for your CNC machining services?