Alloy Steel vs Carbon Steel: What’s the Difference and When to Use Each?

Steel is one of the most widely used materials in modern manufacturing and engineering—but not all steel is created equal. Two of the most common types are alloy steel and carbon steel, each with distinct properties, strengths, and best-use scenarios.

Whether you’re designing automotive parts, constructing machinery, or specifying materials for 3D printing or CNC machining, understanding the differences between alloy steel and carbon steel will help you make smarter decisions.

What Is Carbon Steel?

Carbon steel is primarily composed of iron and carbon, with only trace amounts of other elements. It’s typically categorized into:

Low Carbon Steel (<0.3% carbon): Ductile and easy to form; used for sheet metal and structural components.

Medium Carbon Steel (0.3–0.6% carbon): Offers higher strength and hardness; common in axles, gears, and shafts.

High Carbon Steel (>0.6% carbon): Very hard and wear-resistant; ideal for cutting tools and springs.

Pros:

High strength and hardness (especially high-carbon grades)

Cost-effective and readily available

Easy to machine and weld (low- to medium-carbon grades)

Cons:

Lower corrosion resistance

Brittle in high-carbon forms

Limited toughness at extreme temperatures

What Is Alloy Steel?

Alloy steel contains other alloying elements like chromium, nickel, molybdenum, vanadium, or manganese in addition to carbon. These elements are added to enhance specific mechanical or chemical properties.

There are two types:

Low-Alloy Steel (less than 5% alloying elements)

High-Alloy Steel (more than 5%)

Common Alloying Elements:

Chromium: Improves hardness and corrosion resistance

Nickel: Enhances toughness and impact strength

Molybdenum: Increases strength at high temperatures

Pros:

Superior strength and durability

Better corrosion and wear resistance

Excellent performance in extreme conditions (heat, pressure, chemicals)

Cons:

Generally more expensive

Harder to machine or weld in some cases

May require post-treatment (e.g., heat treatment)

Alloy Steel vs Carbon Steel: Key Differences

Property | Carbon Steel | Alloy Steel |

Composition | Mostly iron + carbon | Iron + carbon + alloying elements |

Strength | Moderate to high | Typically higher |

Hardness | Good (especially high-carbon) | Excellent (with heat treatment) |

Corrosion Resistance | Poor | Good to excellent (depending on alloy) |

Cost | Lower | Higher |

Weldability | Easier (especially low-carbon) | Can be more challenging |

Applications | Structural, automotive, tools | Aerospace, pressure vessels, high-stress parts |

When to Use Carbon Steel

Choose carbon steel when:

Cost is a critical factor

Corrosion is not a major concern

The part will undergo machining, welding, or forming

The mechanical demands are moderate

Examples: Frames, fasteners, automotive parts, construction beams

When to Use Alloy Steel

Choose alloy steel when:

You need superior mechanical properties

The part will be used in corrosive or high-stress environments

Heat resistance or wear resistance is important

Examples: Gears, pressure vessels, aerospace components, high-performance tools

Conclusion

Both carbon steel and alloy steel have a vital role in manufacturing, but they serve different purposes. If you’re working on a project and need strength at a low cost, carbon steel may be your best bet. But for high-performance applications requiring toughness, wear resistance, or corrosion resistance, alloy steel is the way to go.

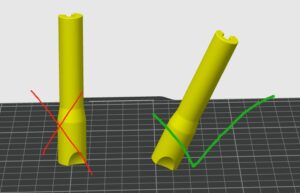

At IN3DTEC, we work with a wide range of steels for CNC machining, 3D printing, and metal fabrication. Simplify upload your parts to our online store to get an instant quote. Not sure which steel fits your needs? Our team is happy to help.