Cost-effective | As fast As one day | Prototyping

Fused Deposition modeling FDM 3D Printing Service

We allow you to rapidly verify your designs with low-cost prototypes.

Simply upload your files by click the below button, get a quote within hours, and go into production within minutes.

What is Fused deposition Modeling?

Fused deposition modeling (FDM) is one of the most widely used additive manufacturing processes for fabricating prototypes and functional parts in common engineering plastics. The simplicity, reliability, and affordability of the FDM process have made the additive manufacturing technology widely recognized and adopted by industry, academia, and consumers.

Many businesses use FDM 3D printing service as it allows the creation of detailed and intricate objects. Therefore, engineers are using it to allow them to test parts for fit and form. It is a technology that is now assisting the creation of small parts and specialized tools that would once take a lot longer to produce.

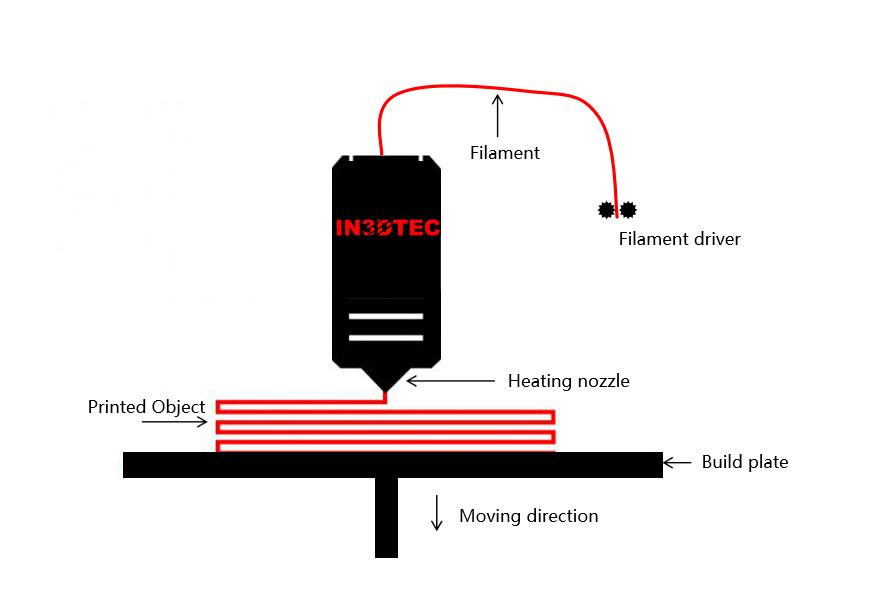

How does FDM 3D printing work?

The process uses a digital design that is uploaded to the 3D printer. There are a lot of different polymers used, such as ABS, ASA, PETG, PETG+CF, PC, Flame retardant, PA+CF, PEI, PPSF, and PEEK.

These take the shape of plastic threads that are fed from a coil and through a nozzle. The filaments are melted and fed onto the base, known as a build platform, both of the plate ad nozzle which are controlled by a computer. The computer works by translating the object and its dimension into co-ordinates that make it possible for the nozzle and base to follow.

Jigs & Fixtures

Electrical Box

See how the world's most innovative companies are using FDM 3D Printing Service for getting prototyping & on-demand production.

The customers Behind Our Success

We Solve Real Problems

The materials available by FDM 3D Printing at iN3DTEC

Key Benefits

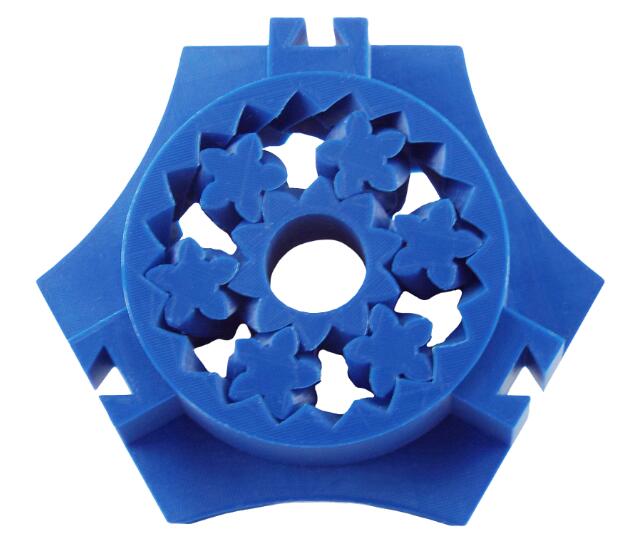

Functional, High stability and impact strength, Complaint to European Toy Safty Norm EN 71-3

Ideal applications

-General-purpose applications

-Housing, Cases

-Electronics

-Low-cost prototyping

Weakness

-Visible line on the surface

-Limited dimensional accuracy

Color

White, Black, Red, Blue, Yellow, Grey, Green…

Surface finish

As printed, Sanding, Painting

Key benefits

UV-resistance, High strength, Chemical resistance

Ideal applications

-Outdoor products

Weakness

-Limited dimensional accuracy

-Visible lines on the surface

Color

White, Black

Surface finish

As printed, Sanding, Painting

Key benefits

Electrostatic discharge protection, Impact resistancen, and toughness

Ideal applications

-Electronics

-Housing & Cases

-Jigs & fixtures

Weakness

-Limited dimensional accuracy

-Visible lines on the surface

Color

Black

Surface finish

As printed, Sanding, Painting

Key benefits

Biocompatible, Smooth surface, Hight stability, and accuracy

Ideal applications

-Medical, e.g. Surgical, medical equipment

Weakness

-Visible lines on the surface

Color

White

Surface finish

As printed, Sanding, Painting

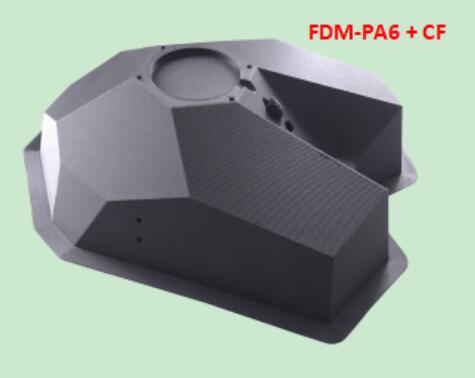

Key benefits

High-temperature resistance, High friction resistance, Excellent, chemical resistance

Ideal applications

-Automotive, Bike, Boat

-Robotics, drones

-Jigs & fixtures

-Tooling

Weakness

Visible lines on the surface

Color

Black…

Surface finish

As printed, Sanding, Painting

Key benefits

Waterproof, Outdoor application, Skin contact safety

Ideal applications

-Outdoor products

-Waterproof products

-Housing & casings

-Consumer products

Color

White, Black, Red, Blue, Yellow, Grey, Green…

Surface finish

As printed, Sanding, Painting

Material Data Sheet>>

Key benefits

High mechanical properties, High notch impact strength, Perfect choice for housing and tools

Ideal applications

-Transportation, automotive, bike, boat

-Jigs & fixtures

-Housings & casings

-Toolings

Weakness

Visible lines on the surface

Color

White, Black, Translucent

Surface finish

As printed, Sanding, Painting

Key benefits

High-temperature resistance (180c degree), High strength and impact strength, Resistance to most of the chemicals, Flame retardant

Ideal applications

-Automotive, Bike, Boat

-Electronics

-Flame retardant products

-Connectors

-Military

Weakness

Visible lines on the surface

Material Data Sheet>>(For this one, please contact our sales directly)

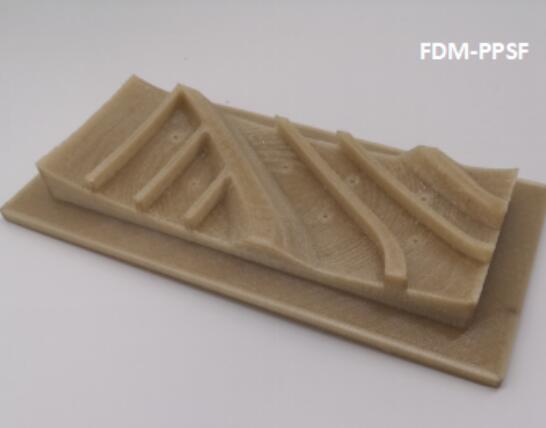

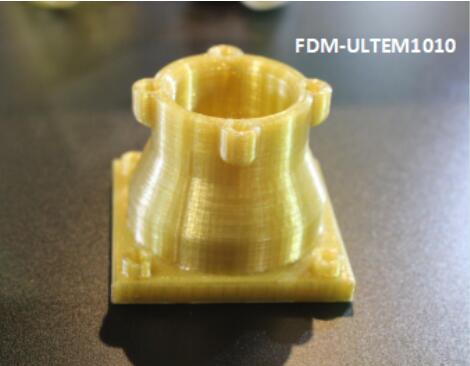

Key benefits

Hight-temperature resistance(190C degree), Super strength, Chemical resistance, Flame retardant

Ideal applications

-Aerospace

-Automotive

-Medical

-Oil & Gas

-Functional products

-Jigs & fixtures

Weakness

Visible lines on the surface

Color

Natural

Surface finish

As printed, Sanding, Painting

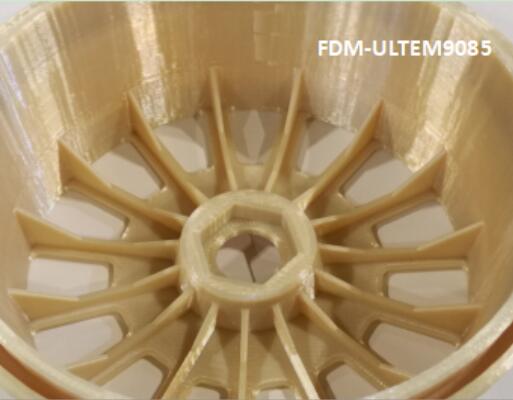

Key benefits

Hight-temperature resistance(190C degree), Super strength, Chemical resistance, Flame retardant

Ideal applications

-Aerospace

-Automotive

-Medical

-Oil & Gas

-Functional products

-Jigs & fixtures

Weakness

Visible lines on the surface

Color

Natural

Surface finish

As printed, Sanding, Painting

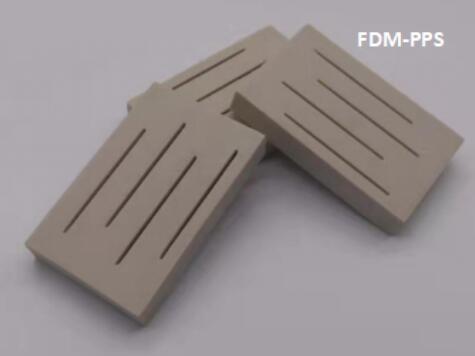

Key benefits

Heat Resistance to 180C degree, Excellent Chemical resistance, Excellent mechanical properties, Flame retardant, Skin or food contact purpose

Ideal applications

-Medical

-Aerospace

-Automotive

Weakness

Visible lines on the surface

Color

Natural

Surface finish

As printed, Sanding, Painting

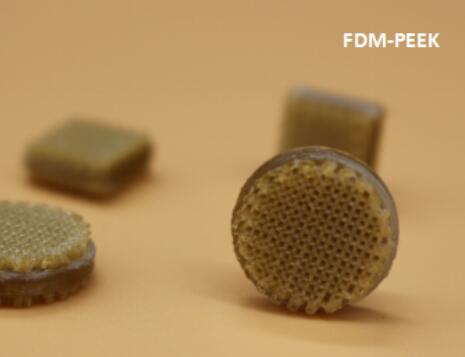

Key benefits

Heat Resistance to 260C degree, Excellent chemical resistance, Flame retardant UL-V0, food contact-free, raditional resistance…

Ideal applications

– Aerospace

-Automotive

-Safety guard

-Electronics

-Military

-Oil & Gas

-Functional & End-use parts

-High strength with lightweight applications

-Chemical resistance applications

Weakness

Visible lines on the surface

Color

Light Brown, Sand-like

Surface finish

As printed, Sanding, Painting

Key benefits

Heat Resistance to 260C degree, Excellent chemical resistance, Flame retardant UL-V0, food contact-free, raditional resistance…

Ideal applications

– Aerospace

-Automotive

-Safety guard

-Electronics

-Military

-Oil & Gas

-Functional & End-use parts

-High strength with lightweight applications

-Chemical resistance applications

Weakness

Visible lines on the surface

Color

Black

Surface finish

As printed, Sanding, Painting

Key benefits

Durable, Shore 85A & Shore 95A, rubber-like

Ideal Applications

-Automotive

-Medical

-Robotics

-Hoses

-Seals

-Footwear

-Helmet interiors

-Toy tires

Weakness

Visible lines on the surface

Color

White, Black, Red, Blue, Yellow, Grey, Green…

Surface finish

As printed, Sanding, Painting

FDM Design Guide

0.8mm

1.0mm

upload Your parts to get a free & instant fDM 3D Printing quote

All upload are secure and confidential

See Our FDM 3D Printing Projects