- Author

- 25 January 2026

Metal 3D Printing: Comparing SLM, Binder Jetting, and DMLS

Metal 3D printing has rapidly transformed from a niche prototyping solution into a reliable production tool used across industries—from aerospace and medical to automotive and industrial machinery. Among the various metal additive manufacturing technologies available today, Selective Laser Melting (SLM), Binder Jetting, and Direct Metal Laser Sintering (DMLS) stand out as the most widely adopted.

But which one should you choose for your next project? Let’s explore the differences, strengths, and ideal use cases of each process.

What is SLM (Selective Laser Melting)?

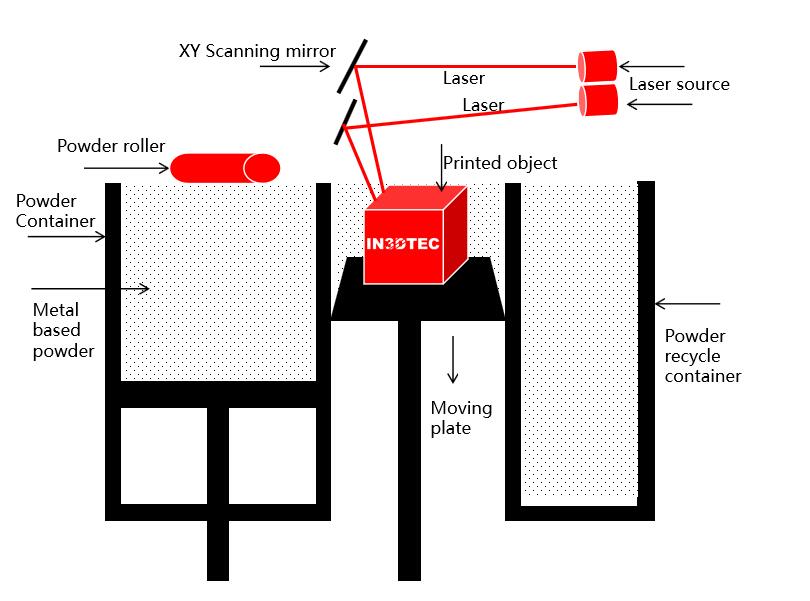

SLM is a powder bed fusion technology that uses a high-powered laser to completely melt metal powder particles together layer by layer. This results in parts with near-wrought density and excellent mechanical properties.

Key Advantages:

High-performance components: Ideal for aerospace, defense, exhaust & pipes for automotive, bike spare parts, electronic casing and housings, drones & robotics, and medical applications.

Excellent strength and density: Comparable to traditional manufacturing, with 99.9% printing density, powder fully melted.

Compatible with high-strength alloys: Titanium, Aluminium, Maraging steel, Cobalt Chrome, copper, Inconel, stainless steel, etc.

Considerations:

Requires support structures and post-processing (e.g., heat treatment, surface finishing).

Slower than Binder Jetting for large volume(thousands of pieces) parts

What is Binder Jetting?

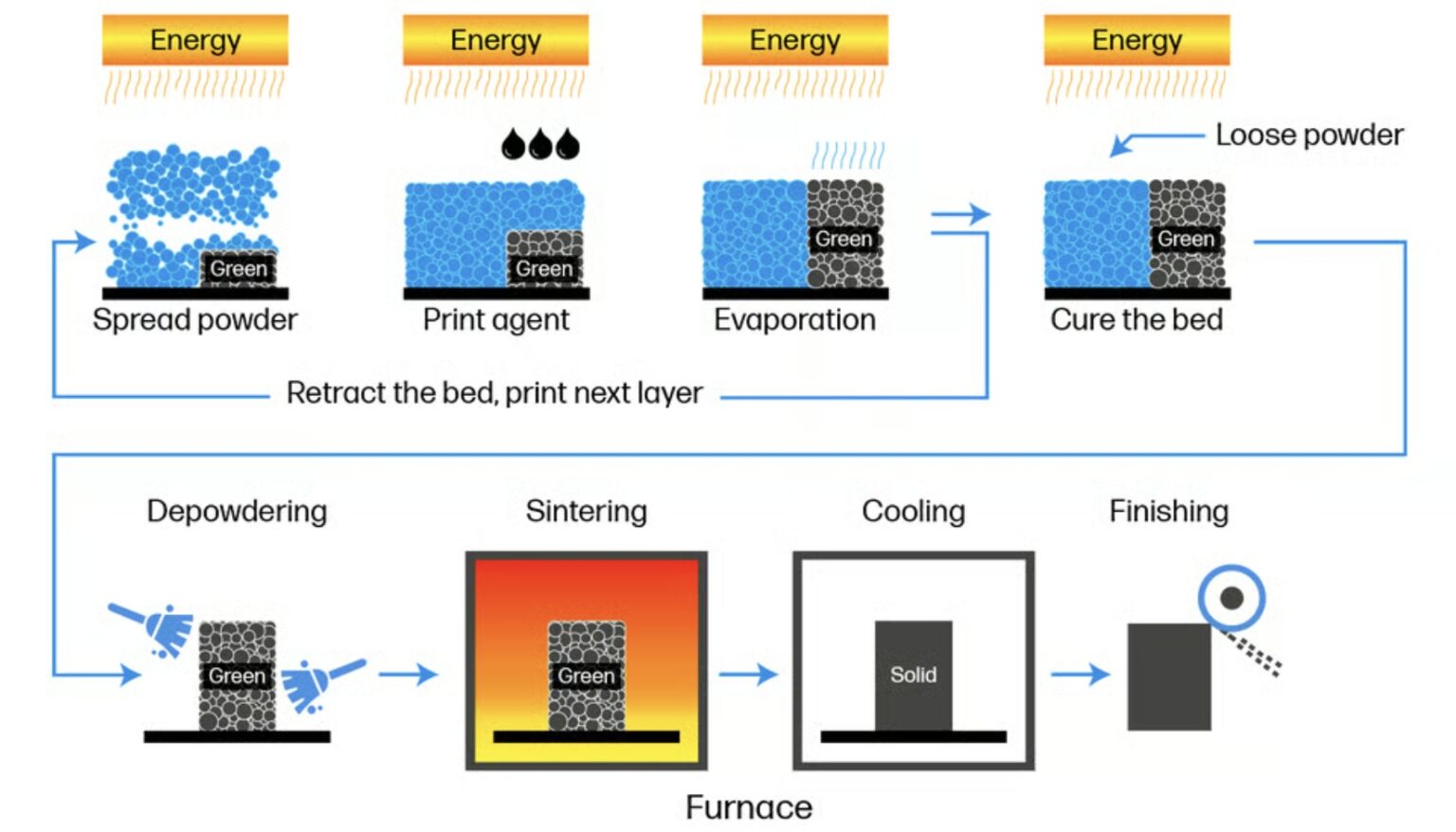

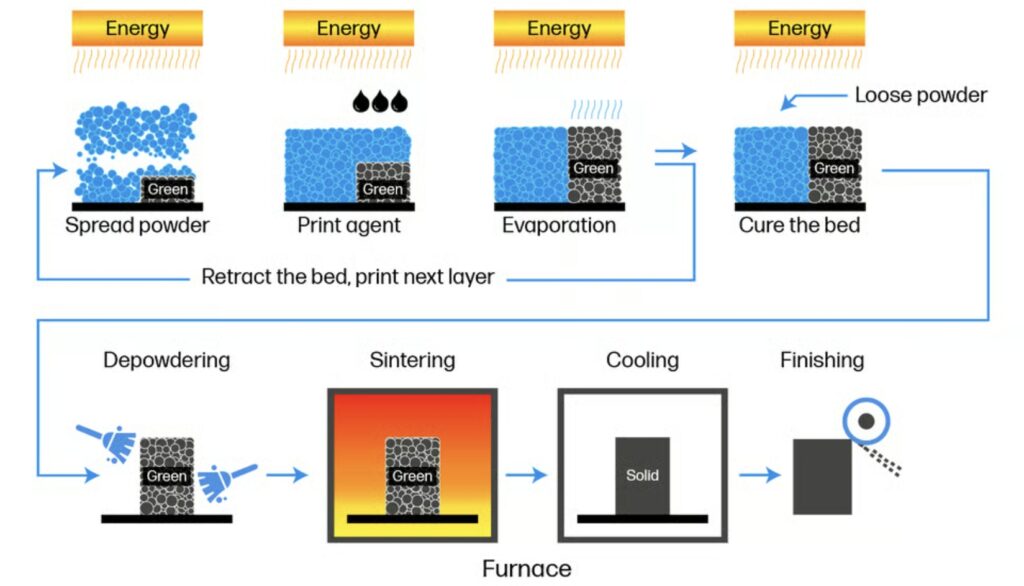

Binder Jetting is an additive manufacturing process where a liquid binder is selectively deposited to join metal powder particles together. After printing, the part (called a “green part”) is cured, then sintered in a furnace to fuse the powder into a dense metal object.

Key Advantages:

High-speed printing: Significantly faster than laser-based methods for large parts.

No support structures needed: Parts are printed within a bed of powder.

Considerations:

Typically produces parts with lower density and strength than SLM or DMLS.

Requires sintering and potentially infiltration with another material (e.g., bronze).

Surface finish is better than SLM/DMLS but still requires post-processing for tight tolerances.

What is DMLS (Direct Metal Laser Sintering)?

DMLS is similar to SLM but operates slightly differently. While SLM melts the powder completely, DMLS sinters the metal powder at a temperature just below its melting point, fusing it together.

However, at present, most researchers and companies have come to treat SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering) as essentially the same technology. For example, although many mainstream metal 3D printing manufacturers are actually using SLM technology, they still refer to it as DMLS in public communications. To some extent, this is done to avoid potential patent disputes with a specific metal 3D printing company called SLM Solutions.

This situation is similar to the distinction between FFF (Fused Filament Fabrication) and FDM (Fused Deposition Modeling).

Key Advantages:

Strong and functional parts: Good for end-use parts and functional prototyping.

Material flexibility: Works with a variety of metal alloys.

Precise geometries and fine details: High resolution for complex designs.

Considerations:

Like SLM, DMLS requires support structures and post-processing.

Build speed is moderate, slower than Binder Jetting.

Parts may be slightly more porous than those made with SLM.

Comparison Overview

| Feature | SLM | Binder Jetting | DMLS |

| Density | Very high (~99.9%) | Medium to high (up to ~95%) | High (~98–99%) |

| Surface Finish | Ra7, requires post-processing | Smoother, but still needs finishing | Similar to SLM, often rough |

| Strength | Excellent | Moderate to good (after sintering) | Excellent |

| Speed | Moderate | Very fast | Moderate |

| Cost | Higher | Lower per part in volume | Medium to high |

| Support Structures | Required | Not required | Required |

| Best For | High-performance, critical parts | Medium-strength | Strong, functional parts |

Which One Should You Choose?

Which One Should You Choose?

SLM is ideal when part strength, complexity, and material performance are top priorities—such as for aerospace brackets, turbine components, industrial components, or medical implants.

Binder Jetting is the better option for mass production, especially for parts that do not require maximum strength. And due to its sintering process, deformation increasing on mid-sized or large size part.

DMLS is a middle-ground for creating detailed, high-strength parts for functional testing or limited production runs.

IN3DTEC Metal 3D Printing Services

At IN3DTEC, we offer both SLM and Binder Jetting metal 3D printing services, giving our customers the flexibility to choose the best process based on their part’s function, material needs, and budget. Whether you’re creating a prototype or scaling up to production, our engineering team is here to support you.

Get a Quote

Email: info@in3dtec.com

Try our Online Quoting Tool for instant feedback on your 3D models (STEP, STL, or IGES files accepted).

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文