Nylon 6 | Nylon 11 | Nylon 12 | tPU | Nylon+glass filled | Color dyed | vapor smoothing

Selective laser sintering | SLS 3D Printing service

We allow you to rapidly verify your designs with low-cost prototypes.

Simply upload your files by click the below button, get a quote within hours, and go into production within minutes.

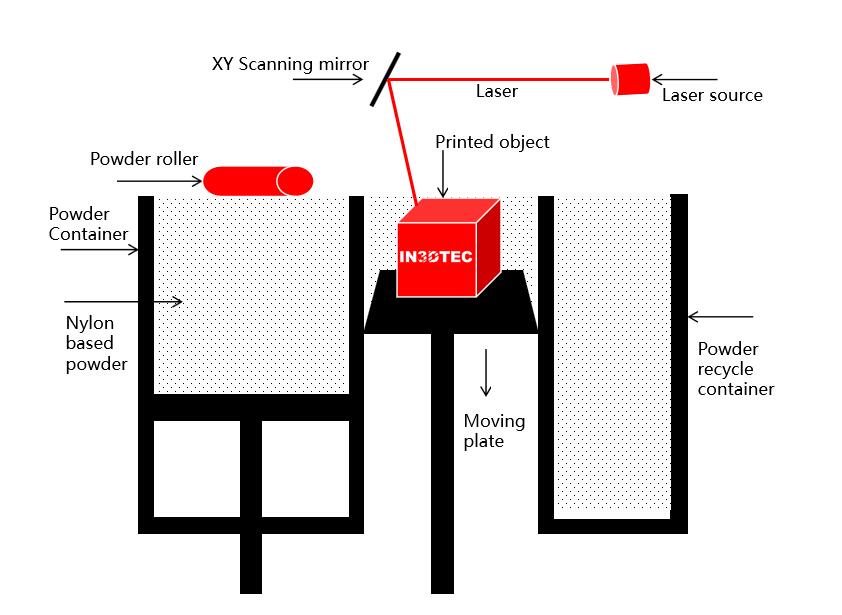

What is selective laser sintering?

Selective laser sintering (SLS) is an industrial 3D printing process that produces accurate prototypes and functional production parts in as fast as 1 day.

It creates highly durable final parts that require heat resistance, chemical resistance, flexibility, or dimensional stability.

With SLS 3D printing, no support structures are required making it easy to nest multiple parts into a single build and an economical solution for when higher volumes of 3D-printed parts are required.

How does SLS 3D Printing work?

6 easy steps for making parts in SLS.

- The powder is dispersed in a thin layer on top of a platform inside of the build chamber.

- Preheats the powder to a temperature just below the melting point of the raw material.

- Laser scans a cross-section of the 3D model, heating the powder to just below or right at the melting point of the material.

- Build platform lowers by one layer into the build chamber, and a recoater applies a new layer of powder material on top. The laser then scans the next cross-section of the build until parts are complete.

- Cooldown the part, move the powder, sand-blasting the surface to make it smooth.

- Dyeing or painting to get more colors

We Solve Real Problems

The materials available by slS 3D Printing Service from iN3DTEC

SLS Design Guide

0.5mm

0.5mm

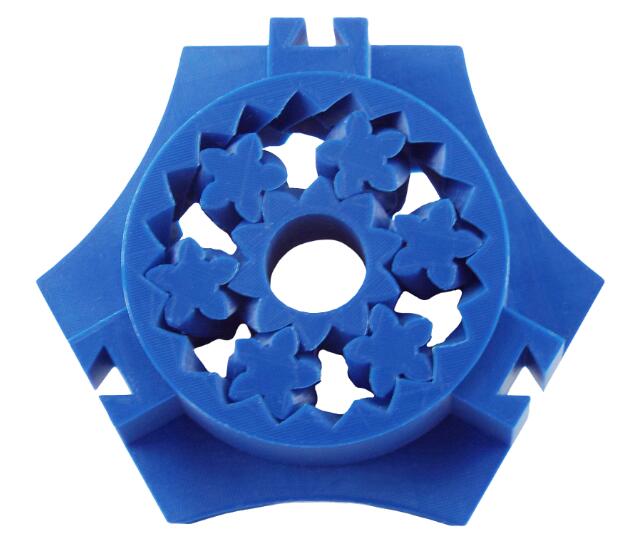

Selective Laser Sintering (SLS)

PA12+Glass bead

Sandblasting + black dyeing

Chemical Resistance, High strength and stiffness, Smooth Surface

Save time

As fast as 1 day

High properties plastics

PA6, PA12, PA+GB with high-temperature resistance, chemical resistance, high toughness, and durable…

Quality assurance & No limitation

SLS 3D Printing with a high accuracy with +/-0.1mm, no support needed, it allow you to design your parts freely…

Cost Save

It allows you to make your part on-demand, and save your mold-free for low-volume production

4 Reasons to Use SLS 3D Printing services

Why choose SLS 3D Printing services?

SLS 3D Printing is now more popular than ever, and businesses all over the world are embracing it to boost productivity, eliminate unnecessary costs, and make new and exciting products and services.

Whether you are an industrial engineer looking for a powerful production solution, or a doctor seeking an efficient way to create prosthetics, SLS 3D Printing is a good choice.

Swimwear

Bike Stopwatch holder

See how the world's most innovative companies are using SLS 3D Printing Service for getting protoyping & on-demand production.

The customers behind our success

Upload your file to get an instant SLS 3D Printing quote

All uploads are secure and confidential

More services