8 Things You Need to Know About Anodizing Aluminum

Introduction:

Aluminum is a versatile metal that is widely used in various industries for its lightweight, durable, and corrosion-resistant properties. One of the most popular surface treatment methods for aluminum is anodizing. Anodizing aluminum not only enhances its appearance but also improves its resistance to wear and corrosion. In this blog post, we will explore eight important things you need to know about anodizing aluminum.

1. What is Anodizing?

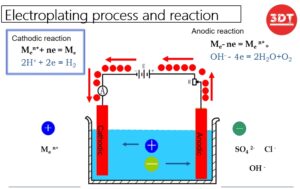

Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum. It involves immersing the aluminum in an electrolyte bath and passing an electric current through it. This causes oxygen ions to combine with the aluminum atoms, creating a thick and durable oxide layer.

2. Benefits of Anodizing Aluminum:

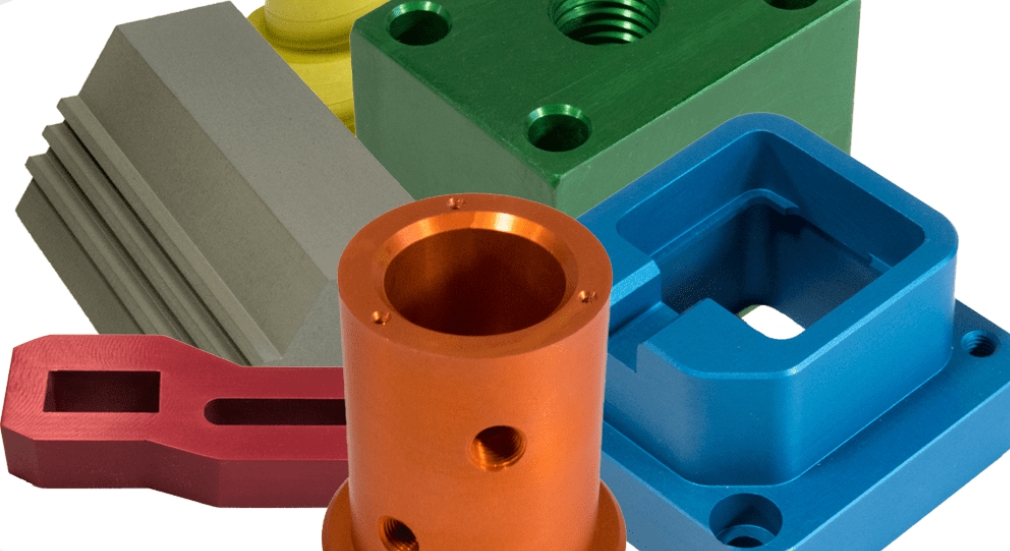

Anodizing offers several advantages for aluminum products. Firstly, it significantly improves the metal’s corrosion resistance, making it suitable for outdoor applications. Secondly, anodized aluminum has enhanced wear resistance, making it more durable and long-lasting. Additionally, anodized aluminum provides an excellent base for coloring and dyeing, allowing for a wide range of aesthetic options.

3. Different Types of Anodizing:

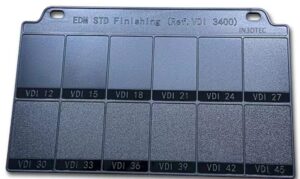

There are three main types of anodizing processes for aluminum: Type I, Type II, and Type III. Type I anodizing, also known as chromic acid anodizing, produces a thin and porous oxide layer, primarily used for cosmetic purposes. Type II anodizing, or sulfuric acid anodizing, creates a thicker and more durable oxide layer, suitable for both decorative and functional applications. Type III anodizing, also called hardcoat anodizing, produces an even thicker oxide layer, resulting in superior wear and corrosion resistance.

4. Surface Preparation:

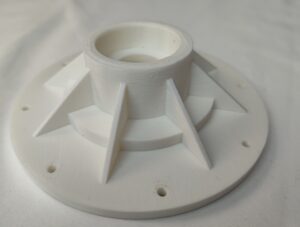

Before the anodizing process, proper surface preparation is crucial. The aluminum surface needs to be thoroughly cleaned to remove any dirt, grease, or oxide layers. This can be done through mechanical methods such as sanding or chemical cleaning. Surface preparation ensures that the anodized layer adheres well to the aluminum surface, resulting in a high-quality finish.

5. The Anodizing Process:

During anodizing, the aluminum part acts as the anode and is submerged in an electrolyte solution. A direct current is passed through the electrolyte, causing oxygen ions to react with the aluminum surface, forming the oxide layer. The thickness of the oxide layer can be controlled by adjusting the duration of the process. Once the desired thickness is achieved, the aluminum is rinsed and sealed to preserve the anodized layer.

6. Coloring and Dyeing:

Anodized aluminum can be further enhanced with color. The porous nature of the anodized layer allows dyes to penetrate and become trapped within the oxide structure. This results in a wide range of color options for anodized aluminum products. The colorants used are typically organic dyes or inorganic pigments, offering excellent fade resistance and durability.

7. Sealing the Anodized Layer:

After anodizing, the aluminum part undergoes a sealing process to close the pores of the oxide layer. Sealing improves the corrosion resistance and enhances the durability of the anodized finish. Common sealing methods include hot water sealing, steam sealing, and chemical sealing. The choice of sealing method depends on the specific application requirements.

8. Applications of Anodized Aluminum:

Anodized aluminum finds widespread use in various industries. It is commonly employed in architectural applications for its aesthetic appeal, weather resistance, and low maintenance requirements. Anodized aluminum is also utilized in the aerospace industry, automotive components, consumer electronics, and sporting goods. Its ability to combine functionality with visual appeal makes it a popular choice across diverse sectors.

Conclusion:

Anodizing aluminum is a highly effective surface treatment that enhances the properties and appearance of the metal. Understanding the anodizing process, its types, and the benefits it offers can help you make informed decisions when it comes to utilizing anodized aluminum in your projects. Whether you are looking to improve corrosion resistance, add color, or increase the durability of your aluminum products, anodizing provides an excellent solutio