How to Print PET-CF: A Comprehensive Guide

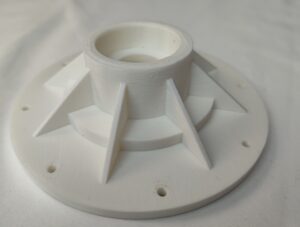

3D printing with PET-CF (Polyethylene Terephthalate Carbon Fiber) can elevate your projects due to its superior strength, stiffness, and thermal resistance. However, working with PET-CF requires specific considerations to achieve optimal results. This guide will walk you through the steps and tips for successfully printing with PET-CF.

What is PET-CF?

PET-CF is a composite material made by infusing carbon fibers into PET (Polyethylene Terephthalate) filament. This combination results in a material that is:

– Stronger and stiffer than standard PET, it has a tensile strength of 78Mpa

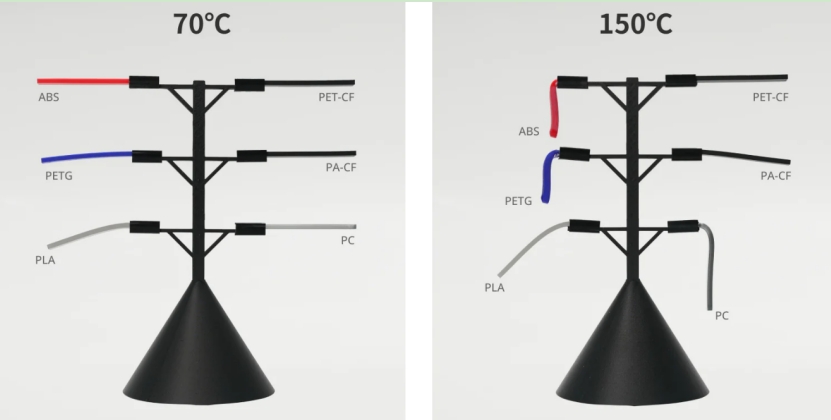

– Heat resistant 150℃, making it suitable for high-temperature applications.

- Specimen size (L*W*H): 95*10*4 mm³

• Test conditions: Specimens were put in an oven at 70 °C and 150 °C respectively for 0.5 hour.

• As a crystalline material, PLA will significantly deform only after the temperature exceeds its melting point (around 155°C).

• Image Source: Bambulab

– Lightweight, with improved structural integrity due to the carbon fibers.

How to Prepare Your 3D Printer for PET-CF?

- Printer Compatibility:

– Ensure your 3D printer has a hardened steel nozzle. Carbon fibers are abrasive and can wear down standard brass nozzles quickly.

– A heated bed is essential, ideally one that can reach temperatures up to 110°C.

- Nozzle Size:

– Use a nozzle size of 0.6mm or larger to prevent clogging. PET-CF can have small carbon fiber fragments that may clog smaller nozzles.

- Extruder Type:

– A direct drive extruder is preferable over a Bowden setup, as it provides better control over the filament.

Printing Settings

1. Temperature:

– Extruder Temperature: Set between 240°C and 260°C. Start at a lower temperature and gradually increase if the filament does not extrude smoothly.

– Bed Temperature: Set between 100°C and 110°C. Use a bed adhesive like PEI or Kapton tape or PVA glue to ensure good adhesion.

2. Print Speed:

– Print at a moderate speed, around 60-90 mm/s. PET-CF requires slower speeds for better layer adhesion and surface finish.

3. Layer Height:

– A layer height of 0.25mm is ideal for balancing detail and strength.

4. Cooling:

– Enable part cooling fans but keep them at a low setting (around 20-30%) to avoid warping.

Preparing the Filament

1. Dry the Filament:

– PET-CF is hygroscopic, meaning it absorbs moisture from the air. Dry the filament in a filament dryer at 70°C for 4-6 hours before printing.

2. Storage:

– Store PET-CF in a sealed container with desiccant packets to keep it dry when not in use.

Printing Tips

1. First Layer:

– Ensure your first layer is well-calibrated. A good first layer adhesion is crucial for the success of the print. Adjust the bed leveling and Z-offset as necessary.

2. Adhesion:

– Use a wider brim( double layers if possible) or raft to improve bed adhesion and prevent warping, especially for larger prints.

3. Support Structures:

– PET-CF can be challenging to remove supports from, so use a minimal support structure or a dual extrusion setup with a soluble support material like PVA.

4. Post-Processing:

– PET-CF prints can be sanded or machined to achieve a smooth finish. Be cautious of the carbon fibers, as they can create fine dust that should not be inhaled.

Troubleshooting Common Issues

- Nozzle Clogs:

– If you experience nozzle clogs, increase the print temperature slightly or use a larger nozzle.

- Warping:

– Warping can be minimized by ensuring the bed is properly heated and using bed adhesives or an enclosure to maintain a consistent temperature.

- Stringing:

– Reduce stringing by adjusting retraction settings. Increase retraction distance or speed incrementally to find the optimal settings.

- Layer Delamination:

– If layers are not adhering well, increase the print temperature or slow down the print speed for better layer bonding.

Conclusion

Printing with PET-CF can be challenging but rewarding, offering high-strength and high-heat resistance parts. By following the proper printer setup, filament preparation, and printing techniques outlined in this guide, you can achieve excellent results with this advanced material. Happy printing!