Demystifying Polycarbonate Injection Molding: Everything You Need to Know

Introduction:

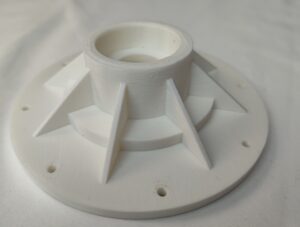

Polycarbonate injection molding is a widely used manufacturing process that offers numerous benefits for producing high-quality, durable plastic components. With its exceptional strength, transparency, and heat resistance, polycarbonate has become a popular choice for a wide range of applications across various industries. In this blog post, we will explore the essential aspects of polycarbonate injection molding and provide you with the knowledge you need to understand this versatile process.

Understanding Polycarbonate:

Polycarbonate is a thermoplastic polymer known for its remarkable combination of strength and transparency. It exhibits excellent impact resistance, making it highly suitable for applications that require durability and protection against breakage. Additionally, polycarbonate offers outstanding heat resistance, allowing it to maintain its mechanical properties even at high temperatures.

The Injection Molding Process:

Polycarbonate injection molding involves several stages, including:

a. Material Preparation: Polycarbonate resin pellets are carefully selected and dried to eliminate moisture, ensuring optimal material performance during the molding process.

b. Melting and Injection: The dried polycarbonate pellets are fed into the injection molding machine’s hopper, where they are heated and melted. The molten material is then injected into a mold cavity under high pressure.

c. Cooling and Solidification: Once injected into the mold, the molten polycarbonate rapidly cools and solidifies, taking the shape of the mold cavity. Cooling time is critical to achieve proper dimensional accuracy and minimize cycle time.

d. Ejection: After solidification, the mold opens, and the newly formed polycarbonate part is ejected from the mold using ejector pins or a robotic arm.

Key Advantages of Polycarbonate Injection Molding:

Polycarbonate injection molding offers several significant advantages:

a. Design Freedom: Polycarbonate’s excellent flow characteristics allow for the creation of intricate shapes and thin walls, offering designers unparalleled freedom to create complex parts with precise details.

b. Impact Resistance: Polycarbonate’s exceptional impact resistance makes it ideal for applications that require protection against potential damage or breakage, such as automotive components, safety helmets, and electronic device enclosures.

c. Optical Clarity: Polycarbonate exhibits exceptional transparency and optical clarity, making it suitable for applications that require excellent visual properties, such as eyewear lenses, LED light covers, and display screens.

d. Heat Resistance: Polycarbonate can withstand high temperatures without significant deformation or loss of mechanical properties, making it ideal for applications exposed to heat, like automotive parts, electrical connectors, and lighting fixtures.

e. Considerations and Challenges:

While polycarbonate injection molding offers numerous advantages, it’s essential to consider some factors and challenges:

- Mold Design: Due to polycarbonate’s high melt temperature, mold design should consider efficient cooling channels to ensure proper solidification and minimize cycle time.

- Material Selection: Different grades of polycarbonate are available, each with specific properties suited for different applications. Material selection should align with the desired mechanical, thermal, and optical requirements.

- Part Warpage: Polycarbonate’s high shrinkage rate can lead to part warpage if not properly controlled. Adequate mold design and process optimization are necessary to minimize warpage.

- Cost Considerations: Polycarbonate can be more expensive than other thermoplastics, so it’s crucial to evaluate the overall cost-benefit analysis for your specific application.

Conclusion:

Polycarbonate injection molding is a versatile process that allows for the production of high-quality, durable plastic components with exceptional mechanical properties and optical clarity. By understanding the fundamentals of polycarbonate injection molding, you can leverage this manufacturing technique to create innovative and reliable products for various industries. Remember to consider key factors such as mold design, material selection, warpage control, and cost considerations to optimize your injection molding process and achieve the desired results.