Functional end-use parts | Competitive Price | As fast as 2 days

multi Jet Fusion | mJF 3D Printing service

All uploads are secure and confidential

What is Multi Jet Fusion?

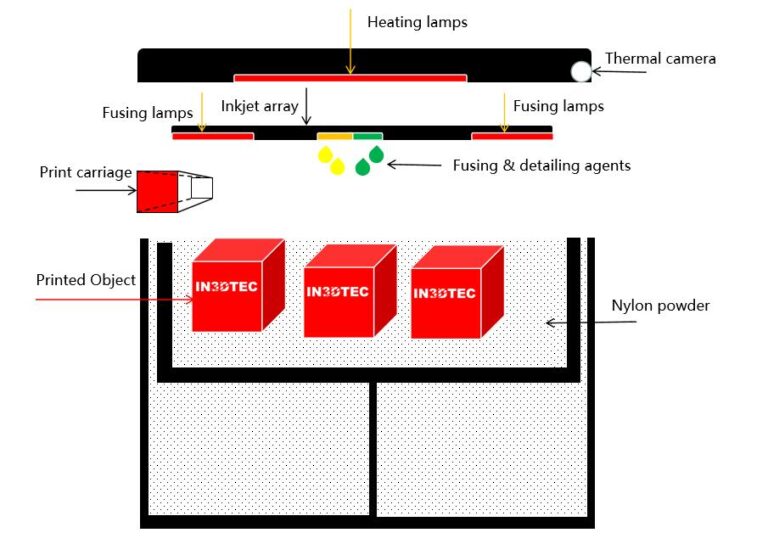

How does multi jet fusion works?

Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by heating elements into a solid layer. After each layer, the powder is distributed on top of the bed and the process repeats until the parts are complete.

When the build finishes, the entire powder bed with the encapsulated parts is moved to a processing station where a majority of the loose powder is removed by an integrated vacuum. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department where they are dyed black to improve cosmetic appearance.

The MJF materials available by iN3DTEC

Key benefits & certifications

USP Class I-VI, US FDA guidance for Intact Skin Surface Devices, Excellent mechanical properties, Chemical Resistance, Biocompatibility

Ideal applications

-Wate tight products

-Medical & food contact products

-Cases

-Eye frames

-Drone parts

-Home decor

-Prosthetics

Key benefits

USP Class I-VI, RoHS6, EU REACH, High-temperature resistance (170C degree), Excellent mechanical properties, Waterproof, Chemical resistance

Ideal applications

-Mechanical & structural parts

-Mounts, cases

-Eye frames

-Tech accessories

-Drone parts

-Art

-Prosthetics

Key benefits

Hight-temperature resistance (186C degree), Excellent mechanical properties, Hot water-free

Ideal applications

-Tooling

-Robotics

-Drones, Fixtures

-Medical Braces-

Housings & Cases

Multi Jet Fusion (MJF)

PA12+Glass bead

Sand blasting +Black dyeing

Chemical Resistance, High strength and stiffness, Smooth Surface

Tooling | Robotics | Drones | Fixtures | Medical braces | Housing & Cases

Free e-book of 3D Printing

MJF Design Guide

0.6mm

0.8mm

Save time

As fast as 2 days

High performance materials

High durable, toughness, chemical resistance, and high-temperature resistance PA12, PA12+Glass filled.

Quality assurance & no limitation

Multi Jet Fusion with a higher accuracy within +/-0.2mm, high-quality with repeatable. No limitation to the designs

Cost Save

Save your cost of mold-fee for low volume production under 1000 pieces

4 Reasons to Use 3D Multi Jet Fusion MJF 3D Printing service

Why choose multi Jet Fusion services?

Multi Jet Fusion is now more popular than ever, and businesses all over the world are embracing it to boost productivity, eliminate unnecessary costs, and make new and exciting products and services.

Whether you are a designer looking for a powerful prototyping solution, or a business owner or engineer seeking an efficient way to make your parts on-demand, Multi Jet Fusion printing is a good choice.

Fluid Pipeline

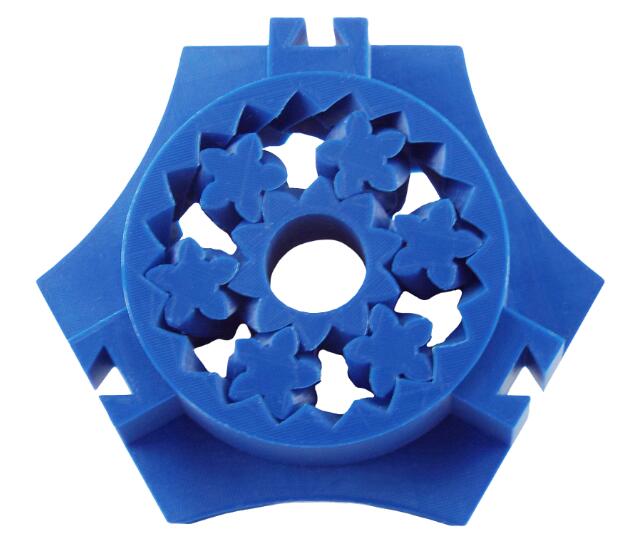

Wheel Cover

See how our multi jet fusion 3d printing service benifits our customers

The customers Behind Our Success

More services