Top 8 Design Tips For Reducing CNC Lead Times

Are you afraid of the cost of this machining technology? Do not stress over your head because our 8 design tips for reducing CNC lead times can prove a panacea for you.

If you need customized parts on an immediate basis or urgent requirements for a prototype to showcase to your customers while in the meeting, CNC machining can make these dreams come true.

Computer Numerically Controlled Machining (CNC) is a cutting-edge technology in the field of subtractive manufacturing processes for the production of precise and customized components from raw materials.

CNC is revolutionary manufacturing technology for many industries, including aerospace, automotive, medical, and consumer electronics, where quality and precision are paramount.

Keeping high accuracy and producing high-quality components makes the CNC machining procedure expensive. It results in an increase in CNC lead times and financial costs.

In this article, we share eight design tips for reducing CNC lead times and costs during its operations in order to make this manufacturing technology cost-effective for your enterprise.

Tip 1: Simplifying Designs to Reduce Complexity

The more intricate your input designs are, the more equipment arrangements and operations they demand.

Instead of customizing complex designs with intricate characteristics or deep cavities, try simple geometries as much as possible with fewer finishing features to alleviate your CNC lead times and operations.

Tip 2: Minimize the Number of Steps

Lowering operation steps would prove beneficial for minimizing CNC machining time. To make this possible, you should adhere to these pointers as

- Disintegrate your larger components into smaller ones and finalize the end product through their assembly.

- Either machine your parts in a single step or consolidate numerous elements into a single procedure.

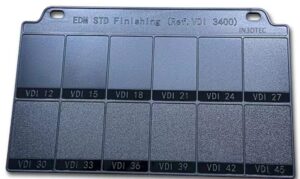

Tip 3: Design with Standardized Tools and Materials

There is no difficulty in finding standardized tools since they are readily available in a global market and known for their high performance and long life.

Second, standardized input materials are easy to buy from any shop, and they are convenient to design and machine.

Third, obeying a standardized procedure is very quick and cheap. For example, fabricating standardized threads is easier compared to customized threads.

Employing these design tips for reducing CNC lead times would have many positive effects during CNC operations.

Tip 4: Concern for the Tooling Requirements of Your Design While CNC Machining

Before proceeding to CNC operations, set your list of tooling, as the utilization of fewer tools or minimal tool changes will aid in a decrease in CNC lead times.

Make a production chart by optimizing tooling paths. It is essential since the shorter the tooling path, the less time it takes to form a final product.

Tip 5: Mitigating Tolerances

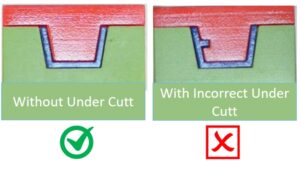

Tight tolerance limits will prove more time-consuming and costly for your CNC operations because you should do more operations to fix this issue.

It is recommended to you that you stick to lose tolerance limits as much as possible to reduce the number of operations and machining time. This production strategy will not only minimize your hard work in machining but also in CNC lead times.

Tip 6: Design with the Machining Process in Mind

Your first objective is to clarify all concepts of your procedural steps, potential issues, and capabilities before the inception of the CNC operation.

Choose a simple design that is conveniently machined with common CNC tools and equipment since complicated designs or hard-to-reach aspects need extra tooling time and specialized tools.

Plan a sequence of CNC machining operations in advance to reduce confusion during the process, which results in more time consumption.

Tip 7: Select Your Materials Meticulously

Some CNC materials are hard to machine, so it is your responsibility to avoid them by optimizing your material selection in accordance with minimizing the time to machine your components.

It leads to minimal material waste, reducing material handling time, and the number of materials that need to be machined away.

Tip 8: Test, Optimize, Stimulate, and Prototype

Before leading to full-scale production, ensure that you have tested the prototype on simulation software like Finite Element Analysis Programme to evaluate the potential causes, forecast its functioning, and optimize your design. It results in saving your budget and CNC lead times in production via CNC machines.

Key Takeaways

Implementation of the above eight design tips for reducing CNC lead times and even more on the cost of CNC operations.