Injection moulding is a very useful manufacturing procedure for mass production of goods with similar shapes. Giving different aesthetics by introducing a variety of colouring options is a difficult and time-consuming process.

This problem has been completely eradicated by two-color injection molding.It enables professionals to manage product moulding with two separate materials and colours simultaneously. This operation is cost-effective and time-saving.

Want to know more about this injection moulding machine? The guide will let you learn everything on it and its benefits.

About Two Color Injection Molding

Sequentially Injection of two thermoplastic resins of separate colours in the same mould through different methods is termed “two-color injection molding.” Such moulded products are made of consistent patterns or irregular moiré colors.

This injection moulding technology allows manufacturers to improve the practicability and visual aesthetics of the plastic components throughout.

Utilizing this moulding technique, an injection moulding machine makes mind-blowing multi-functional moulded products in one step, which is in high demand among industries.

What about Two Color Injection Molding Machine

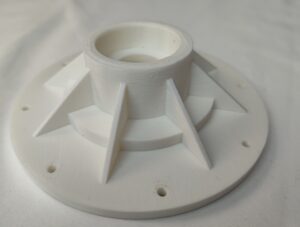

A two-color injection moulding machine is successful in processing two plastic materials of different colours at the same time. It is made up of two injection units, each of which executes one material at a time.

The moulding machine enables manufacturers to inject two color materials at the same time or at different times as per the product specifications. It depends on how much time you need to complete your production requirements.

Toothbrushes of two or more colours are good examples of using these injection machines. Moreover, it is beneficial in the creation of electronic parts, power tools, medical parts, household appliances, and almost all plastic parts.

What are the Advantages of Two Color Injection Molding Machine?

This injection moulding machine is very useful for many enterprises, especially aerospace, automobiles, and manufacturing. Let us figure out each benefit in an open way.

It injects two resins of respective hues with different properties in a single blow. In this way, it reduces our efforts to do assembly and post-processing of the moulded product repeatedly.

This equipment is filled with advanced tooling and features. It allows you to maintain high quality and standards, control deformation, and continue the moulding cycle for a limited time.

It brings down the whole loss to 7% less than that of insert moulding or conventional injection molding. Besides, it is helpful in lowering the cost of product manufacturing, which is 20%–30% lower than injection molding.

Considering all the above benefits, it is definitely right to say that two-color injection moulding machines save resources and reduce costs.

Key Takeways

There is no doubt that two-color injection molding machines produce positive results in the manufacturing industry. Its procedure does not consume too much time to fulfil your requirements. It is a faster and very cost-effective technique for improving aesthetics while also decreasing the cost of printing materials.