What is Investment Casting?

Why is it called investment casting?

Investment casting is an industrial process based on lost-was casting, one of the oldest known metal-forming techniques. The term “lost-wax casting” can also refer to modern investment casting processes.

Investment casting has been used in various forms for the last 5,000 years. In its earliest forms, beeswax was used to form patterns necessary for the casting process. Today, more advanced waxes, refractory material and specialist alloys are typically used for making patterns. Investment casting is valued for its ability to produce components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys.

Investment casting is so named because the process invests (surrounds) the pattern with refractory material to make a mold, and a molten substance is cast into the mold. Materials that can be cast include stainless steel alloys, brass, aluminium, carbon steel and glass. The cavity inside the refractory mold is an exact duplicate of the desired part. Due to the hardness of refractory materials used, investment casting can produce products with exceptional surface qualities, which can reduce the need for secondary machine processes.

How the investment casting process works?

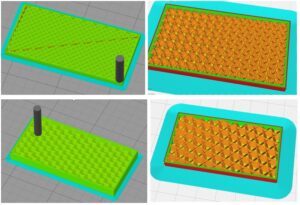

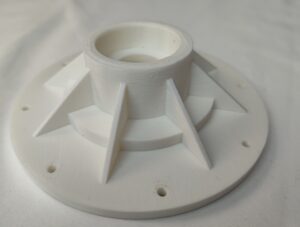

Produce a master pattern: An artist or mould-maker creates an original pattern from wax, clay, wood, plastic or another material. In recent years the production of patterns using 3D printing has become popular using mainly resin based SLA or DLP printers for high resolution patterns or standard PLA filament when high levels of accuracy are not required.

Apply investment materials: The ceramic mould, known as the investment, is produced by repeating a series of steps—coating, stuccoing, and hardening—until a desired thickness is achieved. Coating involves dipping a pattern cluster into a slurry of fine refractory material and then draining to create a uniform surface coating. Fine materials are used in this first step, also called a prime coat, to preserve fine details from the mould. Stuccoing applies coarse ceramic particles by dipping patterns into a fluidised bed , placing it in a rainfall-sander, or by applying materials by hand. Hardening allows coatings to cure. These steps are repeated until the investment reaches its required thickness—usually 5 to 15 mm (0.2 to 0.6 in). Investment moulds are left to dry completely, which can take 16 to 48 hours. Drying can be accelerated by applying a vacuum or minimizing environmental humidity.

Dewax: Once ceramic moulds have fully cured, they are turned upside-down and placed in a furnace to melt out and/or vaporize the wax. Most shell failures occur at this point because the waxes used have a thermal expansion coefficient that is much greater than the investment material surrounding it—as the wax is heated it expands and introduces stress. To minimize these stresses the wax is heated as rapidly as possible so that outer wax surfaces can melt and drain quickly, making space for the rest of the wax to expand. In certain situations, holes may be drilled into the mold before heating to help reduce these stresses(which you can see in this video). Any wax that runs out of the mold is usually recovered and reused.

Burnout preheating: The mold is then subjected to a burnout, which heats the mold to between 870 °C and 1095 °C to remove any moisture and residual wax, and to sinter the mold. Sometimes this heating is also used to preheat the mold before pouring, but other times the mould is allowed to cool so that it can be tested. Preheating allows the metal to stay liquid longer so that it can better fill all mould details and increase dimensional accuracy. If the mold is left to cool, any cracks found can be repaired with ceramic slurry or special cements.

Pouring: The investment mold is then placed open-side up into a tub filled with sand. The metal may be gravity poured or forced by applying positive air pressure or other forces. Vacuum casting, tilt casting, pressure assisted pouring and centrifugal casting are methods that use additional forces and are especially useful when moulds contain thin sections that would be otherwise be difficult to fill.

Divesting: The shell is hammered, media blasted, vibrated, waterjeted or chemically dissolved (sometimes with liguid nitrogen) to release the casting. The sprue is cut off and recycled. The casting may then be cleaned up to remove signs of the casting process, usually by grinding.

Finishing: After grinding, the completed casting is then subject to finishing. This usually goes further than grinding, with impurities and negatives being removed via hand tooling and welding. In the case that the part needs additional straightening, this process is usually carried out by hydraulic straightening presses, which bring the product in line with its tolerances.