Materials for SLS 3D Printing

Selective laser sintering is a popular technology among 3D printing processes as it can be used with a wide range of materials. The most currently used materials can be classified in two categories:

Rigid materials: such as PA12, PA12 Glass-Filles, PA6

Flexible materials: such as TPU

The Nylon PA12

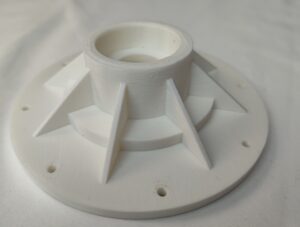

The Nylon PA12 (plastic) objects printed are created from a fine polyamide powder, more commonly known as plastic. Nylon PA12 (Plastic) is great for both experienced professionals and beginning designers because of its high precision and low cost. The good mechanical properties of this nylon material will be for more advanced additive manufacturing projects and can even substitute injection molding plastics. Thanks to its low concentration of amides, it has small moisture absorption, which implies a good resistance to chemicals.

PA12 Glass-Filles

Objects printed in Nylon 3200 Glass-filled (glass-filled nylon) are made from a mix of polyamide powder and glass fibers. The surface of this 3D printing material is white and slightly porous. Our Nylon 3200 Glass-filled (glass-filled polyamide) is more durable and resistant than Nylon PA12.

Using this engineering thermoplastic for 3D printing gives you great freedom in your designs – allowing for both complex and inclosed volumes. The material is great for technical parts that need resistance and loads. The surface of Nylon 3200 Glass-filled (glass-filled nylon) is not as accurate as Nylon PA12 but it will fit the requirements of technical parts. Glass-filled nylon has some good mechanical properties.

PA6

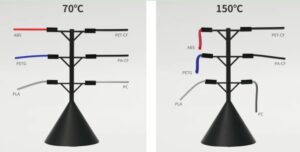

PA6 is one of the most popular engineering polymers for series applications. PA6 is characterized by high strength and rigidity, uncompromising tightness and excellent thermal performance properties. Compared to conventional injection-molded PA6, PA6 shows improved performance with less moisture absorption.

The combination of high heat resistance with excellent mechanical performance makes the material the right choice for demanding technical applications in harsh environments.

TPU

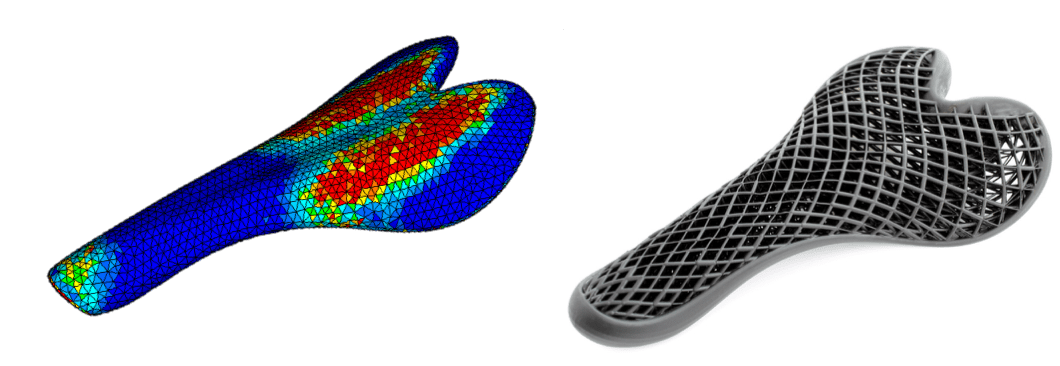

The Selective Laser Sintering TPU (or SLS TPU) is a Thermoplastic Polyurethane material. If you are looking for a resistant, flexible, and rubbery material, this TPU is the perfect option.

With a good resilience after deformation and a high UV stability, this SLS TPU offers numerous advantages for your projects requiring an elastomeric material. By creating an interesting structural design, parts can be 3D printed for various applications, from automotive to footwear industries. The material also offers good hydrolysis resistance, great shock absorption, and a smooth white surface.