An Overview of Stereolithography (SLA) Materials

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enhancing Electronic Products with Vacuum Casting Technology In the fast-paced world of electronics, precision and quality are paramount. The demand for innovative and reliable electronic

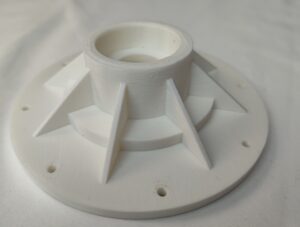

Exploring the Best 3D Printing Settings for HIPS High Impact Polystyrene or HIPS is a standout choice in the world of 3D printing. Known for

Exploring Shapeways Alternatives: Finding the Right 3D Printing Service for You In the rapidly evolving world of 3D printing, Shapeways has established itself as a prominent

Best Dual Extruder 3D Printers in 2024 3D printing technology continues to evolve rapidly, offering new capabilities and enhanced performance. One of the most significant

G and M Codes: Understanding the CNC Programming Languages Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by automating the control of machining

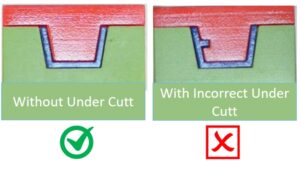

Designing Undercuts for Injection Molding: A Comprehensive Guide When it comes to injection molding, designing undercuts can be a critical aspect that impacts both the

When it comes to injection molding, cost efficiency is often a top priority. One of the primary factors influencing the cost of injection molding is

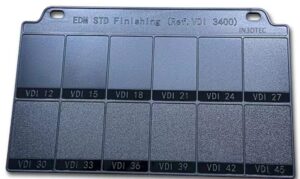

Injection Mold Surface Finishes: VDI vs. SPI When it comes to injection molding, the surface finish of the mold can significantly impact the final appearance

Top 11 CNC Wood Carving/Cutting Machines in 2024 CNC (Computer Numerical Control) machines have revolutionized the woodworking industry, allowing for precise and intricate designs that

Top 10 3D Scanners in 2024 You Should Know The world of 3D scanning has seen remarkable advancements over the past few years, making it

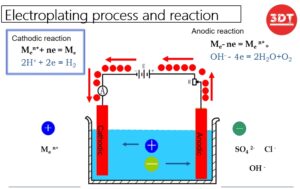

Electroplating vs. Physical Vapor Deposition (PVD) Coating: A Comparative Analysis In the realm of surface finishing and coating technologies, Electroplating and Physical Vapor Deposition (PVD)

How to Print PET-CF: A Comprehensive Guide 3D printing with PET-CF (Polyethylene Terephthalate Carbon Fiber) can elevate your projects due to its superior strength, stiffness,

Keep posted on the release of Coupon Code. The latest news of 3D Printing, CNC Machining, Injection Molding, and Silicone Molding…