The Best ABS 3D Printing Settings: Achieving Optimal Results

Introduction:

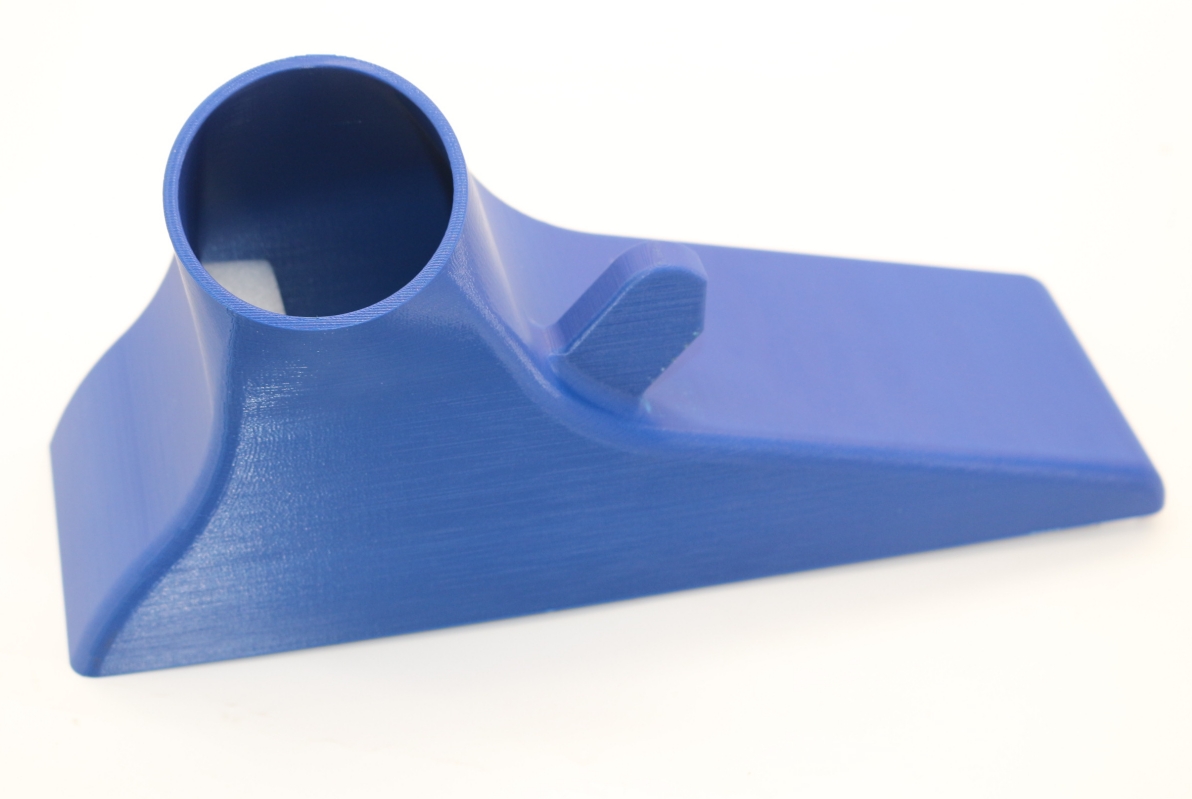

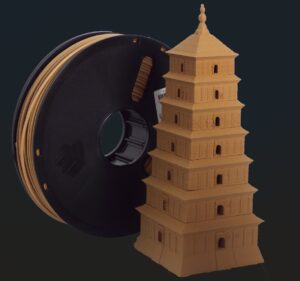

ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic material widely used in 3D printing due to its strength, durability, and heat resistance. However, achieving optimal results with ABS can be a bit challenging, as it requires careful consideration of various printing parameters. In this blog post, we will explore the best ABS 3D printing settings that can help you achieve superior print quality and maximize the potential of this versatile material.

1. Bed Temperature:

One of the key factors in successfully printing with ABS is maintaining an appropriate bed temperature. ABS tends to warp and lift from the print bed if the temperature is too low. Set your bed temperature between 100-110°C to ensure proper adhesion and minimize warping issues. Additionally, using a heated build plate or applying an adhesive like Kapton tape, PVA glue, or ABS juice can further enhance bed adhesion. It will be great if you have a PEI plate.

2. Nozzle Temperature:

ABS requires a higher nozzle temperature compared to other filaments. Set your nozzle temperature between 230-250°C to achieve optimal flow and ensure that the material is properly melted. Keep in mind that different 3D printers may have slight variations in temperature requirements, so it’s essential to refer to the manufacturer’s recommendations and conduct calibration tests if needed.

3. Enclosed Print Chamber:

ABS is prone to cracking or warping when exposed to temperature fluctuations, especially during the cooling process. To mitigate this issue, consider 3D printing with ABS in an enclosed print chamber. The temperature of the chamber recommended to be 40°C- 65C, An enclosure helps maintain a consistent temperature throughout the printing process, reducing the chances of warping and improving print quality.

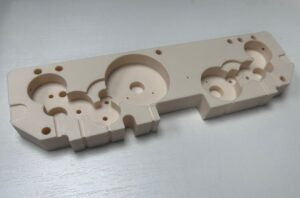

4. Print Speed and Layer Height:

When printing with ABS, it is recommended to use slower print speeds compared to other filaments. Slower speeds allow better control over the material flow and improve adhesion between layers. Start with a print speed of around 60-90mm/s and adjust as needed based on the specific characteristics of your printer. Similarly, using a smaller layer height, such as 0.1-0.2mm, can help achieve finer details and smoother surfaces.

5. Cooling and Ventilation:

Unlike PLA, ABS does not benefit from excessive cooling during the printing process. Cooling fans can cause rapid temperature changes, leading to warping and layer adhesion issues. Therefore, it is advisable to either disable or minimize cooling fan usage( 1st layer must be off, fan can be on from 3rd layer) when printing with ABS. However, good ventilation in the printing area is crucial due to the fumes released by ABS. Ensure proper airflow or consider using a dedicated air filtration system to maintain a safe and healthy environment.

6. Post-Processing and Bed Removal:

After completing the print, it is important to let the print cool down gradually inside the enclosed print chamber to minimize the chances of warping. Once the print has cooled, remove it from the bed with care. Using a flexible build plate or applying a release agent like 3D printing adhesive sprays can make bed removal easier and reduce the risk of damaging the print.

7. ABS Chemical smoothing

ABS smoothing is a technique used to improve the surface finish of ABS objects. By applying specific chemicals, such as acetone, the ABS surface is dissolved and then re-solidifies, resulting in a smoother appearance. Other solvents like ethyl acetate or MEK can also be used. However, caution must be exercised, as proper ventilation and safety measures are necessary. Control over the exposure time is crucial to avoid over-smoothing, which can compromise fine details and structural integrity. ABS smoothing by chemical methods enhances the aesthetics and surface quality of ABS objects, making them more suitable for various applications, including manufacturing and consumer products.

Conclusion:

Printing with ABS can be a rewarding experience when the right settings are applied. By optimizing bed and nozzle temperatures, using an enclosed print chamber, adjusting print speeds and layer heights, and considering cooling and ventilation requirements, you can achieve exceptional results with ABS 3D printing. Remember to experiment, fine-tune the settings based on your specific printer, and embrace the versatility of ABS to bring your creations to life with strength and durability.