FDM vs. SLA vs. SLS: Which 3D Printing Technology Should You Choose?

When it comes to 3D printing, choosing the right technology can make a big difference in the success of your project. Among the most commonly used 3D printing technologies are FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each has its strengths, weaknesses, and ideal use cases. In this article, we break down the differences to help you make an informed decision.

FDM (Fused Deposition Modeling)

FDM is the most widely used 3D printing method, especially for rapid prototyping and low-cost applications.

Printable materials in FDM: ABS,ASA, Carbon fiber, PETG, PLA, PC, PP, PEEK, PPS, PPSU, PEI, POM, NYLON12/66, TPU/TPE(70A, 85A, 92A, 98A, 65D all are available from IN3DTEC 3D printing service)

Pros:

Cost-effective and widely accessible

Easy to operate and maintain

A wide range of thermoplastics available.

Good for functional prototypes and low-tolerance parts

Cons:

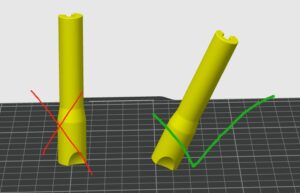

Lower resolution and surface finish compared to SLA and SLS

Visible layer lines

Limited geometric complexity

Best for: Quick and affordable prototypes, basic mechanical parts, early-stage product development, fixtures and jigs

Applications:

Consumer product housings

Automotive test parts

Educational and concept models

Jigs and fixtures

SLA (Stereolithography)

SLA uses a UV laser to cure liquid resin into solid parts and is known for its high precision and fine details.

Printable materials in SLA: Standard ABS, Tough ABS, Somos Evolve, Somos Ledo, Somos Taurus, Ceramic

Pros:

Excellent resolution and surface finish

Ideal for detailed, intricate designs

Tight tolerances and minimal post-processing

Cons:

More expensive than FDM

Brittle material properties

Limited selection of resins compared to FDM thermoplastics

Best for: Highly detailed models, dental and medical components, visual prototypes, and molds

Applications:

Dental molds and aligners

Housing & Casings for all products

Jewelry prototypes

Medical device casings

High-detail display models

SLS (Selective Laser Sintering)

SLS uses a laser to fuse powdered materials (usually nylon) into solid parts. It does not require support structures, making it suitable for complex geometries.

Printable material in SLS: Nylon, Nylon+GF, Nylon+CF, PP, PEEK, TPU

Pros:

Strong, functional parts with good mechanical properties

No need for support structures

Excellent for complex assemblies and interlocking parts

Cons:

Higher cost and equipment complexity

Rough surface finish that may require post-processing

Longer lead times

Best for: End-use parts, mechanical components, small-batch production, functional prototypes

Applications:

Aerospace brackets and housings

Medical equipment components

Functional gears and hinges

Drone and robotics parts

Which Should You Choose?

Choose FDM if you’re looking for an affordable and fast option for early-stage designs or mechanical parts that don’t require high precision.

Go with SLA when you need fine details, smooth surfaces, or prototype models for presentation or fit testing.

Opt for SLS if you’re producing functional, load-bearing parts with complex geometries or small production runs.

Still unsure? Reach out to our team through [email protected] —we’ll help match your design with the right technology based on your budget, timeline, and performance requirements.