Exploring the Costs of Metal 3D Printers

Introduction:

Metal 3D printing has revolutionized the manufacturing industry by enabling the production of complex metal parts with high precision. As the technology continues to advance, many businesses and individuals are curious about the cost of owning a metal 3D printer. In this blog post, we will delve into the various factors that affect the cost of metal 3D printers and provide a comprehensive overview of the expenses involved.

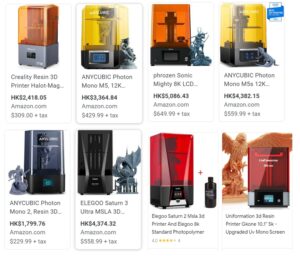

1. Types of Metal 3D Printers:

There are different types of metal 3D printers available in the market, each with its own unique features and price range. The four main categories are:

- Powder Bed Fusion (PBF) printers

- Directed Energy Deposition (DED) printers

- Binder Jetting printers

- Fused deposition modeling(FDM) printers(extruding metal filled filament)

2. Initial Investment:

The cost of a metal 3D printer primarily depends on the technology and specifications. Entry-level systems can start at around $50K, while high-end industrial-grade printers can cost from 300K up to several million dollars. Factors that influence the price include build volume, laser power, precision, and automation features.

3. Consumables of metal 3d printers:

Metal 3D printing service requires consumables such as metal powders, gas supplies, powder mixer, wire cutting machine, and support remove tools. The cost of these consumables varies depending on the type of metal being used and the desired quality of the final product. Metal powders can range from a few hundred dollars to thousands of dollars per kilogram.

4. Maintenance and Upkeep:

Like any other piece of equipment, metal 3D printers require regular maintenance to ensure optimal performance. Maintenance costs may include replacing worn-out components, calibrating the machine, and conducting routine inspections. It’s important to consider these ongoing expenses when budgeting for a metal 3D printer.

5. Post-processing and Finishing:

Metal 3D printed parts often require post-processing to achieve the desired surface finish and mechanical properties. This can involve processes like heat treatment, machining, polishing, and coating. The costs associated with post-processing should be taken into account when evaluating the overall expenses of metal 3D printing.

6. Training and Software:

Operating a metal 3D printer requires skilled personnel who are knowledgeable about the technology and its specific parameters. Training programs and software licenses can add to the initial investment. It’s important to factor in the costs of training and software updates to ensure efficient and safe operation of the printer.

7. Facility and Infrastructure:

Metal 3D printers require a suitable environment with proper ventilation, temperature control, special power, enough space and safety measures. Setting up the necessary infrastructure, including dedicated workspace, power supply, and safety equipment, should be considered when calculating the overall cost of owning a metal 3D printer.

8. Examples of metal 3D printers’ cost

|

Name |

Technology |

Cost |

|

|

EOS – M 100 |

Powder Bed Fusion (PBF) |

$350,000 |

|

|

Arcam – Spectra H |

|

$100,000 – $250,000 |

|

|

HP |

Binder jetting |

$400,000.00 |

|

|

Farsoon, FS121M |

Powder Bed Fusion (PBF) |

$400,000.00 |

|

|

Velo3D |

Powder Bed Fusion (PBF) |

$500,000.00 |

|

|

SLM Solutions SLM125 |

Powder Bed Fusion (PBF) |

$400,000.00 |

|

|

Markforged, Metal X |

Fused deposition modeling(FDM) |

$99,500.00 |

Conclusion:

The cost of a metal 3D printer can vary significantly depending on factors such as technology, specifications, consumables, maintenance, post-processing, training, and infrastructure. While the initial investment can be substantial, the benefits of metal 3D printing, such as reduced lead times, design freedom, and cost-effective production of complex parts, make it an attractive option for many industries. It’s advisable to thoroughly research different models, consult with suppliers, and assess your specific requirements before making a purchasing decision. By understanding the various costs involved, you can make an informed choice and unlock the potential of metal 3D printing for your business or personal projects.