- Author

- 25 February 2026

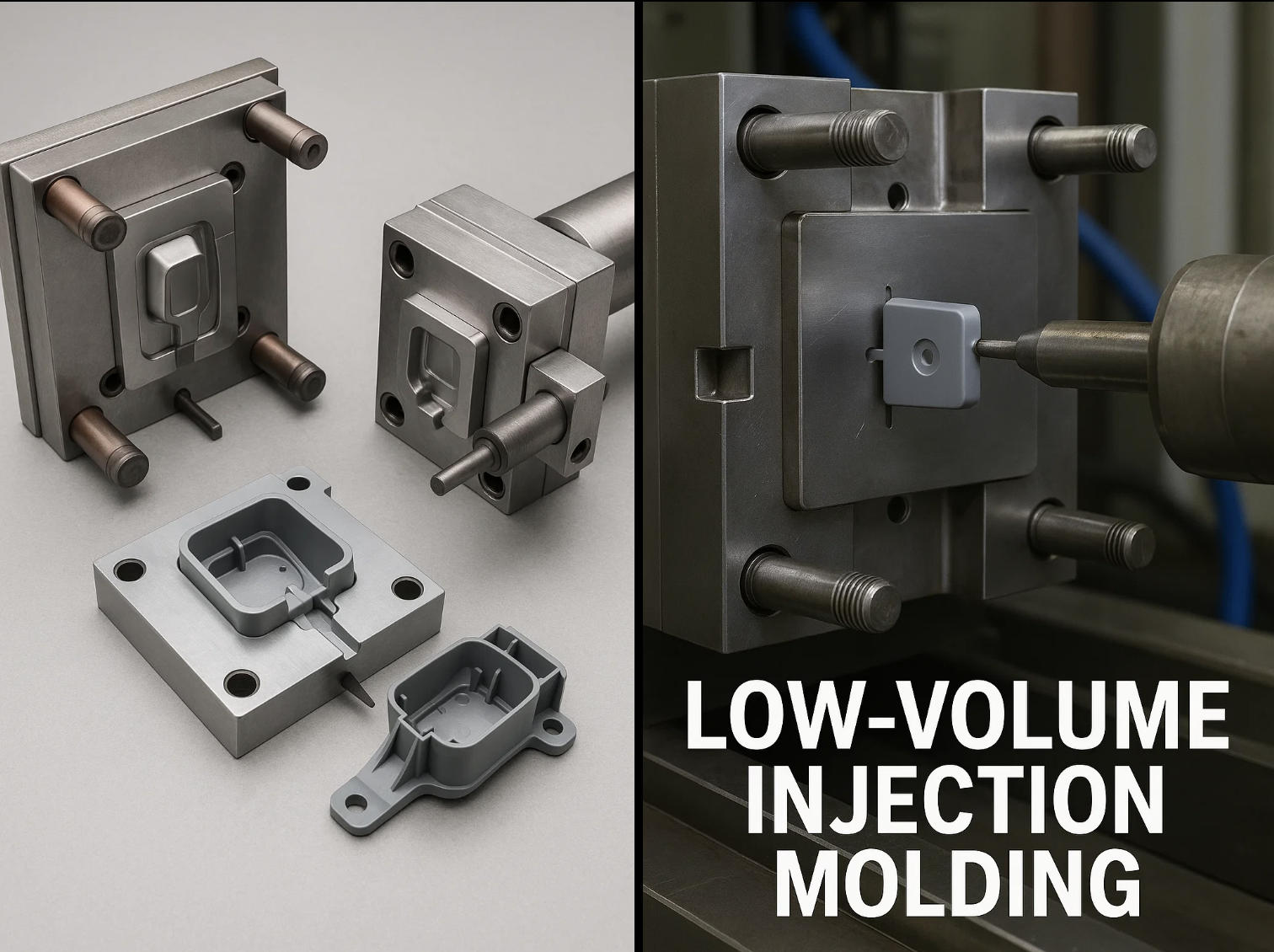

Low Volume Injection Molding: A Smart Choice for Prototyping and Short-Run Production

In today’s fast-paced product development cycle, low volume injection molding has become a popular manufacturing option for startups, engineers, and design teams. Whether you’re preparing for mass production, testing form and function, or creating a bridge tool before high-volume tooling is ready, low volume injection molding strikes the perfect balance between cost-efficiency and product quality.

What Is Low Volume Injection Molding?

Low volume injection molding refers to the process of producing a limited number of plastic parts—typically anywhere from 100 to 10,000 units—using simplified or rapid tooling, such as aluminum or soft steel molds. These molds are faster and more economical to produce than hardened steel molds used in high-volume production, making them ideal for:

Functional prototyping

Market testing

Pilot production

Custom or seasonal products

Benefits of Low Volume Injection Molding

Cost-Effective Tooling: Aluminum molds are much cheaper than traditional steel tooling, reducing upfront costs significantly.

Faster Lead Times: Mold fabrication and part production can often be completed within 2–4 weeks.

High Repeatability: Even with short runs, parts made with injection molding exhibit excellent consistency, detail, and finish.

Material Versatility: You can use a wide range of thermoplastics (ABS, PP, PC, PA, TPU, etc.) in the same machines used for high-volume production.

Challenges of Low Volume Injection Molding

Despite its advantages, low volume molding comes with trade-offs:

Tooling, even if cheaper, still involves lead time and upfront investment.

Design changes after tooling starts can be costly.

For quantities under 100 units, it may not be the most cost-effective option.

3D Printing as an Alternative to Low Volume Injection Molding

When part quantities are very low (e.g., <200 pcs) or frequent design iterations are required, 3D printing becomes a compelling alternative.

Top 3D Printing Technologies for Low-Volume Production

Selective Laser Sintering (SLS)

Materials: Nylon (PA12, PA11), TPU

Strengths: Great for functional parts, flexible or rigid, no support structures, excellent mechanical strength

Available Surface finishes: Vaporfuse Smoothing, Polishing, Electroplating, Painting, Tumbling.

Materials: PA12, PA11, PP, TPU, PA12 with glass beads

Strengths: Faster than SLS, strong and isotropic properties, ideal for enclosures, brackets, mechanical components

Available Surface finishes: Vaporfuse Smoothing, Polishing, Electroplating, Painting, Tumbling.

Materials: Resin-based plastics (ABS-like, tough, high-temp), High detail resin

Strengths: Ultra-high resolution, smooth surface, ideal for cosmetic prototypes and molds

Available Surface finishes: Sandblasting, Polishing, electroplating, painting

Fused Deposition Modeling (FDM)

Materials: ASA, ABS, PETG, PC, Nylon+CF, PC-FR

Strengths: Affordable for larger parts, fast iteration, useful for fixtures and jigs

Available Surface finishes: Sandblasting, Polishing, Painting.

Digital Light Processing (DLP) or CLIP

Used for: Dental and small, precise components with production-grade materials

Which One Should You Choose?

| Criteria | Low Volume Injection Molding | 3D Printing |

| Quantity | 100–10,000 pcs | 1–500 pcs |

| Lead Time | 2–4 weeks | 1–5 days |

| Cost (Setup) | High (mold cost) | Low |

| Cost per Part | Low (in high volume) | Higher per unit |

| Design Iteration | Costly | Easy and fast |

| Material Properties | Real thermoplastics | Approaching injection-grade in some cases |

Final Thoughts

If you’re looking to bring your product to market quickly, or if you’re not quite ready for full-scale manufacturing, low volume injection molding is an excellent choice. But if you need faster iteration, smaller batches, or want to avoid tooling costs altogether, 3D printing can offer powerful solutions—especially as the technology and materials continue to evolve.

At IN3DTEC, we provide both low volume injection molding and advanced 3D printing services, helping you choose the best method for your product stage and budget.

Ready to discuss your project? Get an instant quote here or contact our expert team today.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文